The fine folks at Venom Racing Engines recently dialed us up to talk about one of their recent projects, an insane 369 cubic-inch LS engine that’s designed to do one thing: set the class record in C/Gas Altered at Bonneville in 2018.

The record shot will be taken by Andy Loyd and Gene McFaddin of Bad Andy’s Speed Shop in Houston, Texas. But Bad Andy’s Speed Shop isn’t what you think—you can’t buy parts there and can’t have your car built… it’s simply a place for Loyd and McFaddin to play with cars. The car in question that will receive this engine is SloPoke, a highly-modified fourth-gen Camaro that will feature noted tuner Josh Ledford behind the wheel when its Bonneville aspirations become reality.

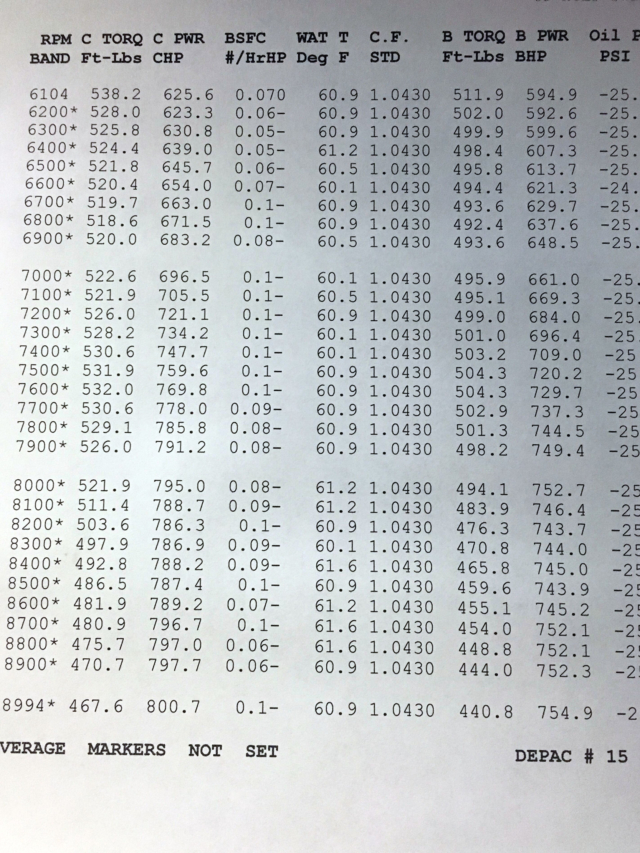

But you came here to learn about the engine that Venom Racing Engines has designed for this beast, so let’s get to it. Venom’s Jim Gray and Reid Sanders are the masterminds of the project, which spun the dyno needle to 800.7 horsepower at 8,994 rpm just before it was shut down.

“Josh approached us last year about building the engine for Andy,” says Sanders.

When you consider that the Bonneville Salt Flats course has a five-mile length, you begin to realize that the engine is required to sing its song for as long as possible to get the car to its maximum speed through the traps. Obviously, tall gearing plays a big part in that capability, but this engine had to be designed to run at maximum RPM for long stretches of time, not the typical few seconds of an all-out drag car running the quarter-mile.

Car owner Andy Loyd, Venom Racing Engines owner/engine builder Jim Gray, and VRE induction specialist Reid Sanders with their creation.

To do this requires a fair bit of engineering prowess from Venom Racing Engines, which developed the engine package in-house.

The foundation is based around an LS Next block from Dart that’s been outfitted with bushed .937-inch lifter bores, 55mm roller camshaft bearings, and a set of piston squirters to help keep the underside of the pistons cool during those looooong pulls on the salt.

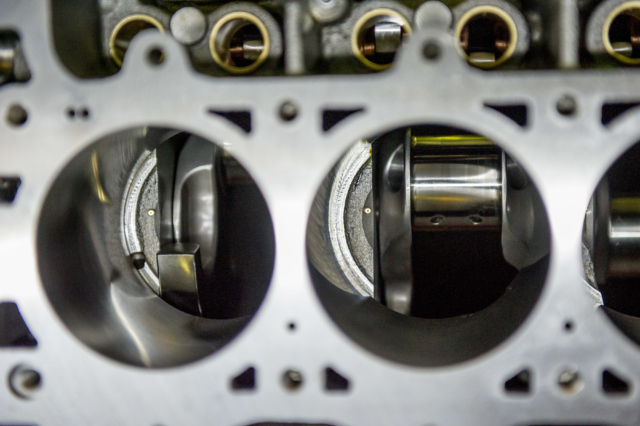

The engine uses a 4.030-inch bore, stock-stroke 3.622-inch Magnum XL lightweight crankshaft from Callies, 6.200-inch connecting rods from Molnar Technologies, and vertical gas-ported CP pistons that were designed to VRE specs with altered ring pack locations and dimensions for this particular combination.

“We added some underhead milling to the pistons to lighten them up, and we’re using DLC-coated pins to help keep friction down. We also have a .9mm/.9mm/2.0mm ring pack on these pistons, and between us being able to finish the cylinder bores right and the Dailey dry sump setup we were able to pull 25 inches of vacuum on the dyno with no additional vacuum pump,” says Sanders.

Eight high-strength soldiers awaiting battle. Sanders says the connecting rods from Molnar Technologies are some of the best they’ve seen at VRE, and they use them almost exclusively in builds under 1,500 hp. Note the vertical gas ports and DLC pins.

We found it interesting that the engine uses the small bore and stock stroke rather than a large bore and long stroke, but according to Sanders, there’s a specific reason these specifications were chosen.

“240 miles per hour is the goal, so in order to be able to pull that at Bonneville you’re going to need a tall gear in it. With that in mind we decided to leave a little more stroke in it and sacrifice the bore size to help pull through that. The torque curve reflected it as it’s pretty flat,” says Sanders.

The small bore means plenty of meat between the cylinders. Sanders says the extra stability helps immensely with ring seal. A Callies Magnum XL crankshaft awaits installation of the rest of the rotating assembly.

To get the compression maxed at 15.8:1, they had Mast Motorsports send its Straight Jacket cylinder heads to CP, where the chamber was digitized to help design the piston dome.

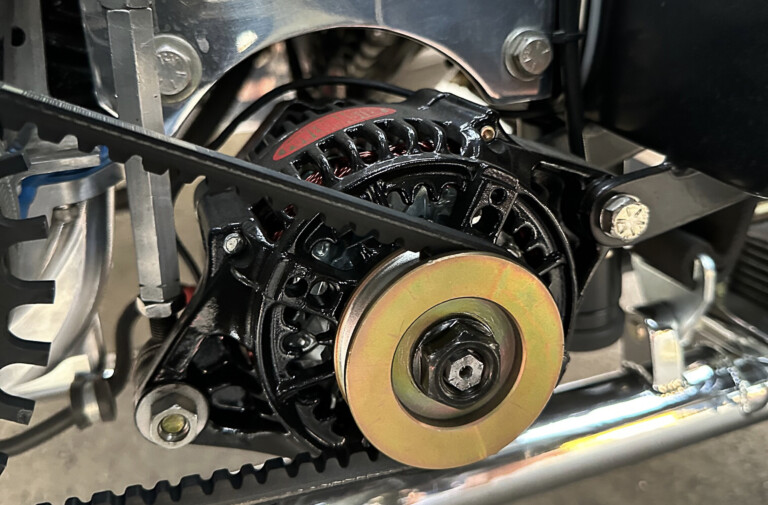

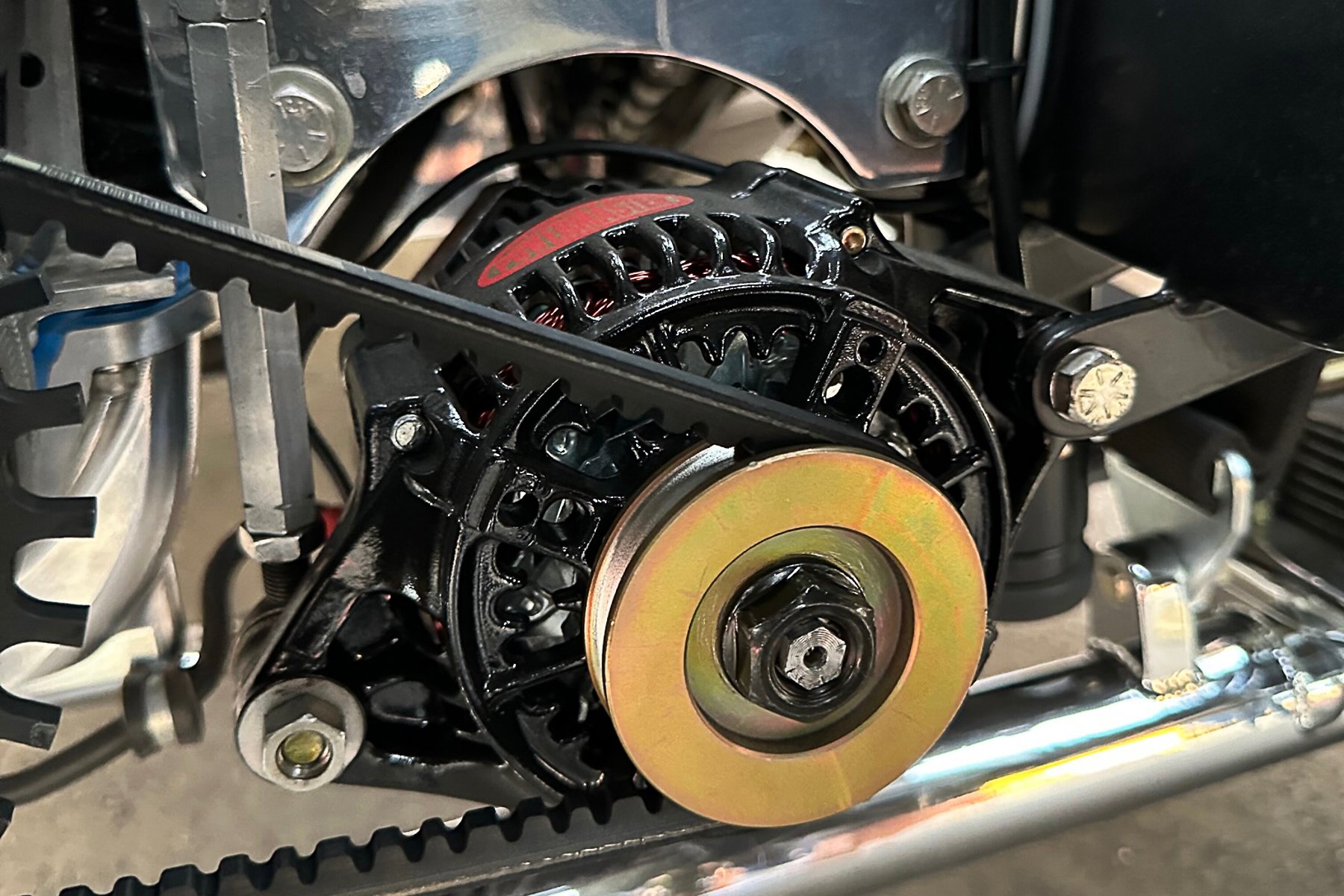

A custom low-lash solid roller camshaft was developed in-house at VRE to get the air into and out of the cylinders efficiently, then brought to life by Cam Motion. Jesel tie-bar roller lifters, belt drive, and rocker arms work in conjunction with Trend 7/16-inch .165-inch-wall pushrods and PAC springs to actuate the Trick Titanium valves. As you might expect, weight reduction in the area of the valvetrain received special consideration.

Using the bushed lifter design–which has a small oiling hole–allowed the VRE team to restrict the oil to the top end of the engine.

The induction system presented its own concerns during the development and tuning process. With a pair of Accufab 6500 four-hole throttle bodies on top of a custom M&M Competition fabricated intake manifold, managing airflow when the throttle is cracked open became a priority.

“The tuning aspect of it was pretty fun—that’s a large door opening on a pretty small engine. We tuned it on the dyno and we’ll be working with Josh when we’re out there at Bonneville. We thought the big throttle bodies were going to be a challenge, but they weren’t. You breathe on the linkage and it goes to 22 percent TPS in a hurry,” says Sanders.

VRE selected the Straight Jacket cylinder heads for one reason in particular.

“They were the baddest heads we could get to work with the 4-inch bore,” says Sanders.

Specific attention is paid to the oiling system for engines that compete at Bonneville. With such long runs, it would be extremely easy for an engine to push all of the oil to the top end, starving the crankshaft of necessary lubrication. Sanders worked through that challenge by employing a number of different engine design elements to prevent the issue as much as possible.

“We wanted to use the roller bearing design for the camshaft because it shuts off the oil supply and keeps more of it at the mains,” says Sanders. “For an extended period of wide-open throttle, we’d rather have the oil at the mains than at the camshaft.”

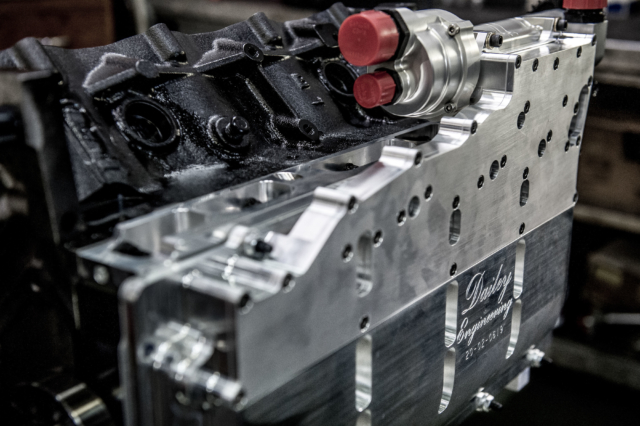

Dailey Engineering’s dry-sump pan and oil pump offers simplicity and consistency for the oiling system.

In addition, a dry-sump five-stage oiling system was sourced from Dailey Engineering to ensure that the oil was scavenged as efficiently as possible to help keep the engine running smoothly. They’re also employing a Spintric air/oil separator to help prevent the oil from foaming.

“It has a billet pan, the pump bolts right to the pan, and there are no scavenge lines. We knew with the piston squirters there was likely to be some windage happening inside the engine, but we were willing to sacrifice that to keep everything oiled,” he says.

Initially, they had a set of valve covers with spring oilers inside, but quickly found out that they might be just a bit too much.

“We were priming the engine with our Peterson primer system, and the drill didn’t make three revolutions and we shot oil three feet out of the rocker adjuster. We decided we weren’t going to hook up the spring oilers on the dyno. We don’t think we’re going to need them at Bonneville either, but they are there and can be used if we start to see something abnormal,” Sanders says.

Keep in mind, though, that Bonneville racers can’t go wide-open on the throttle until after the first mile of the course.

“The salt is like driving on snow. It’s not as hard-packed as everyone thinks it is. I didn’t realize that until we went there this year,” he says.

Even with the challenge of competing on the salt, the Venom Racing engines team feels that this engine—and Andy Loyd’s car—will run the number as expected on the track.