Project Lucky 13 started two years ago with the intent of turning a theft-recovery Camaro into one of the wildest road course carvers around using quality parts and some tuning ingenuity. In the last forty-eight months, we’ve added a roll bar, Z/28 buckets, sticky Toyo tires, incredible suspension, massive Wilwood brakes, cooling upgrades, and more recently—GM’s venerable LS7.

Those of you who have kept up with the surge of reports on Project Lucky 13 won’t be surprised to hear we took the next step and started prepping its LS7 for the demands of the track and addressing the weak points of GM’s soaring, seven-liter engine this time with Peterson Fluid Systems.

Though powerful in the lower revs, the LS7 engine thrives at high RPM—where it requires a steady supply of oil.

The LS7, thankfully, comes suited for the high-performance conditions the car is expected to endure. With parts like titanium connecting rods, a forged steel crankshaft, and CNC ported heads filled with lightweight titanium valves, it’s happy to rev. Thanks to the headwork, it isn’t simply forceful in the low- and mid-range; it provides that exhilarating step near the redline which goads the brave driver to push harder and harder. Such a high-revving and large motor, predictably, requires plenty of oil—which brings us to its weak points.

Loading and Lubrication

However exciting and well-designed the LS7 is, it does have one or two flaws. As many people who’ve used the motor on a road course know, it needs to have its oiling system upgraded for serious track work, since the factory dry sump system has been criticized for not being up to the task on track cars that generate a lot of stick. As our car is bound to spend a good chunk of its life in fast corners, heavy braking zones, and other high-g situations where oil sloshing occurs, we felt that we’d protect our investment with a few carefully chosen pieces to complement the stock LS7 pan and ensure lubrication in the most demanding conditions.

Fancy shoes: Forgeline GA3-R wheels, Toyo R888 tires, and big Wilwood brakes will make Lucky 13 a monster in the corners.

Our Lucky 13 Camaro uses BMR Suspension’s front and rear sway bars, rear lower control arms, trailing arms, and toe rods; Whiteline’s polyurethane bushings, Vogtland coilovers, and sticky Toyo R888s to generate neck-wrenching cornering forces. To keep the occupants stable and secure at speed, we installed a set of Z/28 seats, an Autopower roll bar, and Schroth harnesses.

Understandably, we had to ensure the motor would withstand the lateral loading all those goodies help provide, and to avoid oil starvation that can occur in the middle of a fast corner, we turned to Peterson Fluid Systems for their expertise in this department. Though we considered using some of the Z/28 components. We decided to use the Peterson alternatives since they “outperform the factory pieces in oil control and de-aeration,” says Peterson’s Pat Haberkorn. We were interested in using simple, off-the-shelf pieces with our build, as Lucky 13 is intended to motivate others to try their hand at tuning their car for track work. Therefore, we went with a selection of upgrades that were easily integrated and accessible.

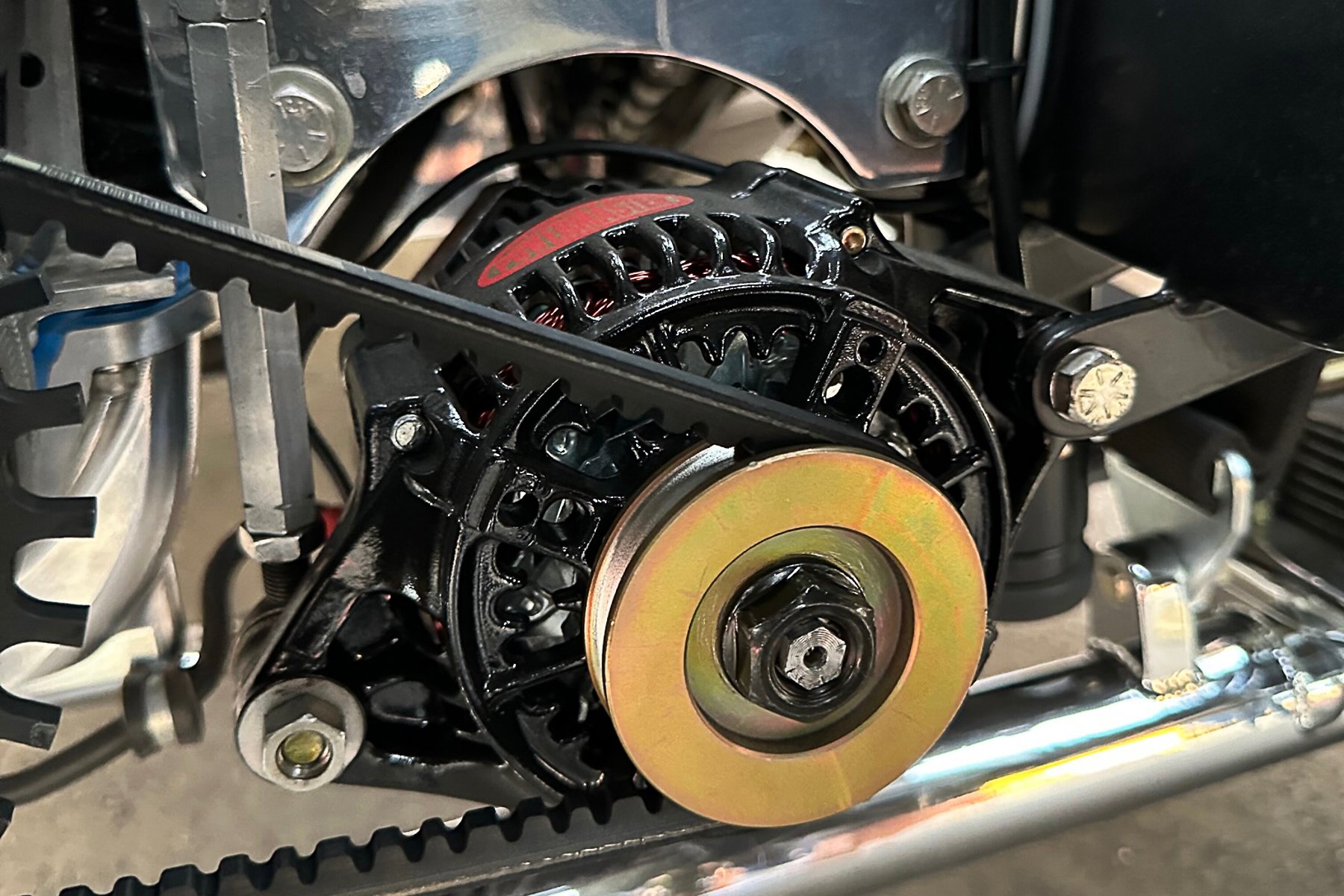

The list of parts we used to avoid the sloshing and oil starvation was small, but made up of quality pieces that fit well within the entire scheme and contributed to overall performance. Not only are the brackets and fittings motorsport-grade and capable of withstanding the jarring and jolting experienced on the road course, they’re also extremely light—we want to keep our Camaro as svelte and athletic as possible.

Peterson’s Oily Bits

Before we added Peterson parts to the mix, we had to install the Z/28’s fans, set up as a pusher-and-puller combo to clear up some space for the sizable tank. We then mounted Peterson’s two-gallon oil tank (P/N 08-00XX) in the Z/28’s factory location—using a little bit of tinkerer’s good sense—to simplify the installation process. If it works on the Z/28, it should work for our purposes.

Peterson’s oil tank is internally baffled, which provides excellent de-aeration of the scavenge oil while maintaining a tall column of oil over the pickup. Additionally, it features a lightweight aluminum composition, high-quality spinnings, and is TIG-welded and pressure tested. What’s more, the tank tops can rotate in relation to the bottoms for ease in fitting placement. Quite simply, this tank is perfect for our purposes.

The low-profile bracket helps the tank fit comfortably in the narrow confines of Lucky 13’s engine bay.

As Haberkorn notes, “The tank is a significant upgrade from stock as the baffling design de-aerates the oil, as well as constrains it around the pickup point. This is

“The tank is a significant upgrade from stock…due to the fact oil can’t slosh away from the pickup point.” –Pat Haberkorn, Peterson Fluid Systems

With a slim bracket, unobtrusive fittings, and a subdued appearance, the Peterson tank fit right into the Camaro’s cramped engine bay. Power Automedia’s Dean Jigamian, the man responsible for installing this collection of parts, comments on this particular piece: “The tank has plenty of cool features like the baffle, the drainplug, and the well-designed, anodized aluminum fittings.”

For ease of installation, the tank tops can rotate in relation to the bottoms, which made this addition a no-brainer.

Next, we opted for Peterson’s 400-series aluminum breather tank (P/N08-0407), which, like the oil tank, is baffled to stop any oil from pushing out of the breather system. The breather tank features a two-stage baffle system, which consists of a spun perforated bell baffle and a fuel cell foam to further separate the oil droplets out of the incoming air.

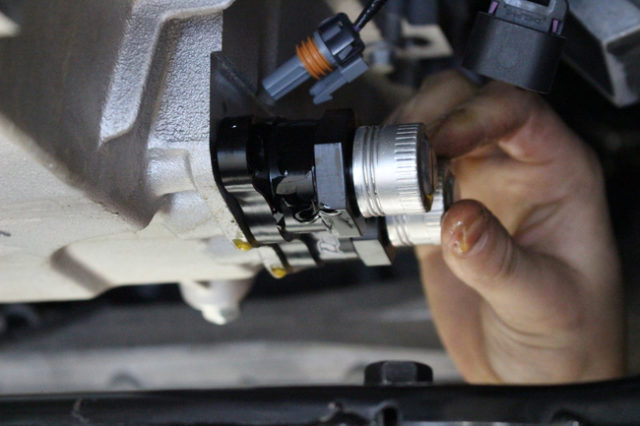

Next on our short but impressive list of upgrades were Peterson’s pan adapter (P/N 15-50X1) and oil cooler adapter fittings (P/N 08-050X), which are both “convenient, cost-effective ways to cleanly convert the factory oil hookup points to AN flare fittings,” Haberkorn says. “They eliminate the need to weld a male bung on to the factory assembly or having to buy multiple adapters to get to the line size required to feed and return oil to the dry sump tank.”

To link all these components together, we used Fragola reusable hose ends, which feature a one-piece design to improve flow characteristics. The design also eliminates brazed ends, which can develop into leak points. The hose ends uses two Viton O-rings, which form a redundant seal which is impervious to fuel, oil and coolant. Our plumbing was first-rate and up to the task of track work.

The pan adapter and oil cooler adapter fittings convert the factory oil hook up points to AN flare fittings, and eliminate the need for a male bung or multiple adapters to feed and return oil to the dry sump tank.

As Lucky 13 will spend plenty of its time at high revs, banging off the limiter and enjoying that soaring top end the LS7 offers, oil temperatures will be high. We were aware that the factory secondary oil cooler—which uses coolant to exchange heat from the oil—wouldn’t be up to the task. Therefore, we picked up one of Derale Performance’s external liquid-to-air oil coolers and mounted it to the radiator. This, hopefully, should provide the cooling needed for repeatable fast laps on a sweltering August afternoon.

Headache-Free Installation

Getting the parts installed was, as you might predict, straightforward. Dean Jigamian, who led the effort, remarks, “the installation was pretty straightforward—the most difficult part was finding a location for the tank. Building the brackets took a little effort, too, but nothing was too demanding.” In less than a few hours, the assembled pieces were resting snugly in their new bay.

Jigamian adds, “As far as adapters go, they all bolt up cleanly.” Because routing of the lines is crucial to the success of this build, we consulted Peterson’s diagrams to be absolutely sure everything was hunky dory. In the end, we had a clean collection of lines that did not scream aftermarket, but added some zest and purpose to the understated stock bay. The Forgeline wheels and sporty stance might’ve done Lucky 13’s curb appeal some good, but the AN fittings and black braided lines are what will have the track rats salivating.

And with that, we had given our Camaro the ability to run quick laps without fear of starvation or overheated oil, all without breaking the bank and keeping a stockish appearance in the engine bay. What’s more—the installation process was simple and painless, and knuckle busting was kept to an all-time minimum. When we take Project Lucky 13 to the track in the not-too-distant future and run a few laps in anger, we can rest assured knowing that the mill is well-prepared for the challenges, and that should—hopefully—free up enough mental energy to figure out how to drive the thing properly. It might be time to start hitting the gym and building up those neck muscles.

For those of you interested in the rest of Project Lucky 13’s lengthy build process, you can enjoy the relevant articles here.