There are numerous aftermarket engine management systems on the market, and one of the newest is the Infinity Stand-Alone Programmable Engine Management System produced by AEM Performance Electronics. The Infinity system has a number of capabilities that are new to the market, and to get a better handle on the system, EngineLabs followed Ryne Cunningham of Cunningham Motorsports while tuning Jeff Jordan’s LS-powered race car.

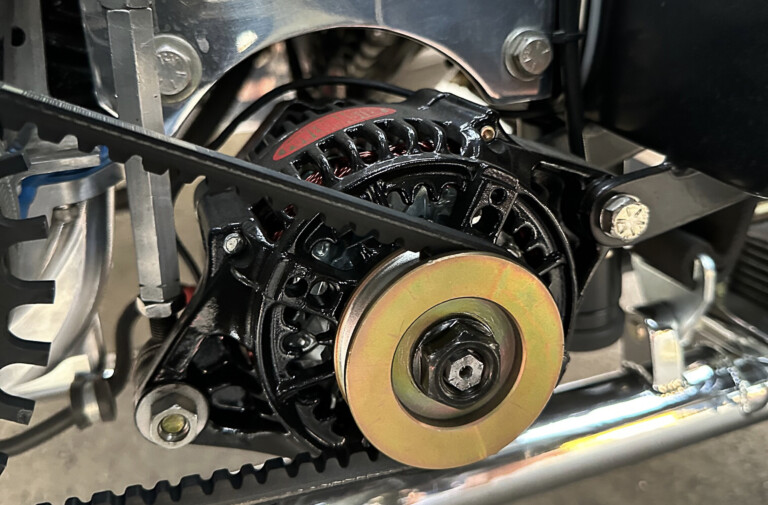

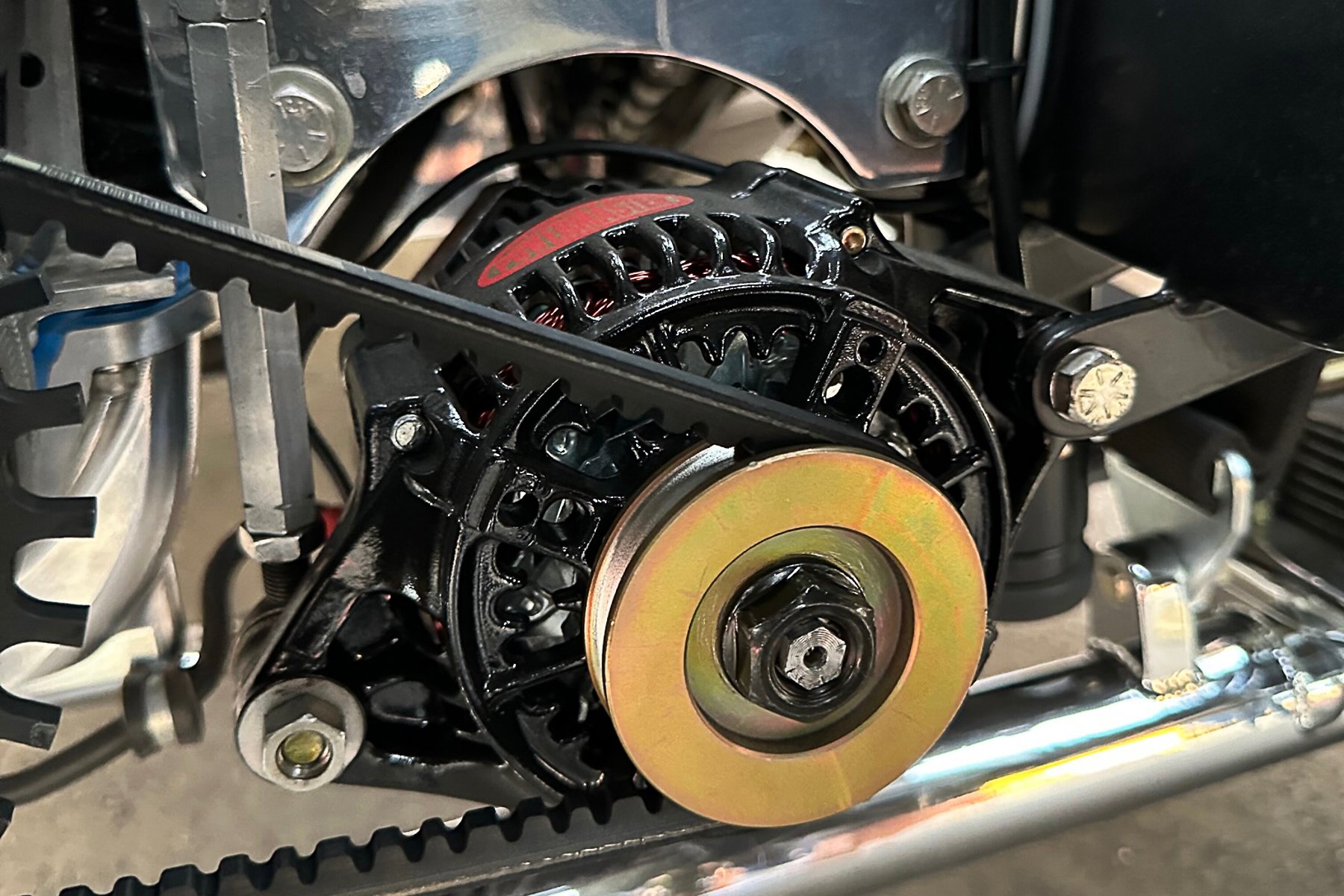

Jordan’s Mazda RX-7 uses an LS3 engine with a Vortech YSi supercharger and plans to make north of 900 horsepower. Jordan built the engine out of his Jordan Innovations shop in Irwindale, California. Cunningham Motorsports specializes in LS-based platforms, so this project was right up their alley.

“Jeff wanted us to tune the car for him, as I’ve done plenty of work on these engines. He wanted us to work directly with AEM,” says Cunningham.

The Infinity system would be a learning experience for Cunningham, so AEM’s Beau Brown helped explain some of the differences between the AEM system compared to the other systems with which he’s familiar.

“It really wasn’t that complicated. I’ve worked with other stand-alone systems in the past, and they are pretty archaic in their design compared to the Infinity. From what I understand, one of AEM’s goals with the Infinity system was to make it simpler to use,” Cunningham explains.

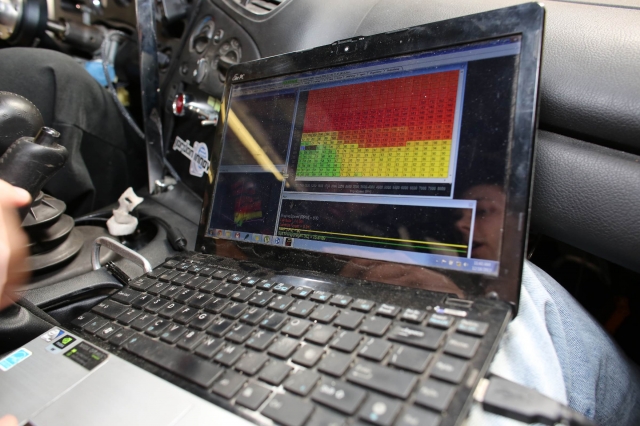

Cunningham typically works with OEM-style tuning systems to properly calibrate customer vehicles, leaving Cunningham a bit of challenge finding specific parameters for adjustment. Once he familiarized himself with the system configuration, the tuning process became more familiar.

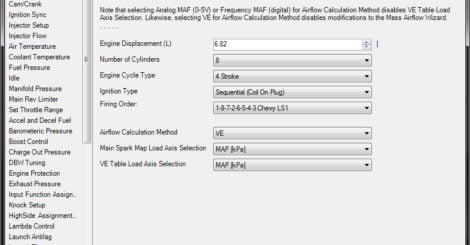

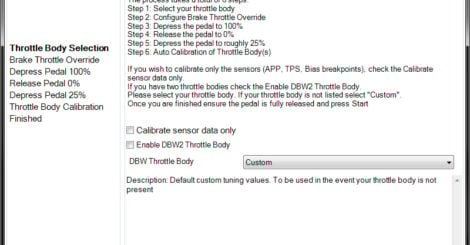

Left - The Startup Wizard in the InfinityTuner software walks the tuner through the steps needed to create a base map for the vehicle. Right - Powerful drive-by-wire controls help the tuner to first calibrate the throttle body's values to enable the system to properly recognize it.

Building the base file

The system uses AEM’s InfinityTuner software to assist the user in building a base file, and Cunningham was very impressed with it.

“It asks how many cylinders you have, what size injectors you’re running, the style of crankshaft pickup, questions like that, and then it builds a base file for you pretty quickly instead of you having to build it from scratch. It asks all of the pertinent questions in order to get you up and running,” he says.

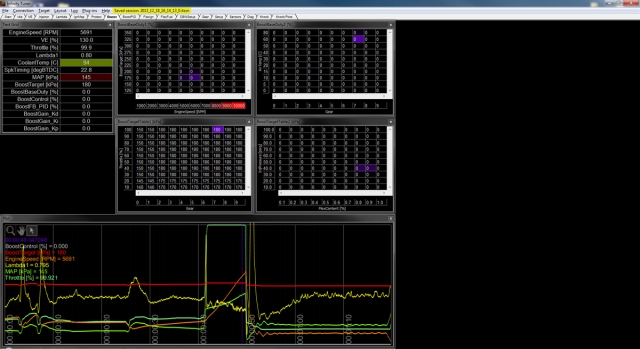

The InfinityTuner software allows the user to choose boost control, idle control, traction control, launch control and more. Each of those controls are synced to real-time logged data provided by the onboard logger, and allows the end user to edit the calibration data during log playback to minimize tuning time. Also included with the system is the AEMdata program, which is the company’s advanced datalogging analysis software that assists in providing more detailed review of those datalogs.

AEMdata will log any parameter available to the engine management system, much like the loggers on the market today – but it’s all built in.

Infinity is one of only two systems on the market to adapt OEM drive-by-wire throttle control, which was helpful with Jordan’s machine.

“The drive-by-wire system was real nice. It was simple to figure out the controls and worked very well,” says Cunningham. “It will allow people with drag- or road-race applications, it will allow them to have a spec for their traction control, so instead of pulling timing, you can actually cut the throttle angle and have even more exact traction control.”

Grasping the controls

“Since I have experience with other systems on the market, Beau was able to show me where the controls were in the Infinity software, and I took it from there. I know what I need to do, they just had to show me in the software where to do it. When you’re working with a stand-alone versus an OEM computer, you’re building a base file – you don’t have a base to work from. It’s more complicated initially, but once you get it going, it’s actually simpler. The factory PCM will have limitations, with the mass airflow sensor and others – you can’t go beyond a certain value, and this one doesn’t,” Cunningham explains.

The X and Y axes for all four tables are user-selectable in the InfinityTuner software. The setup wizard explains each function, and if the user has questions, AEM has free technical support available during normal business hours.

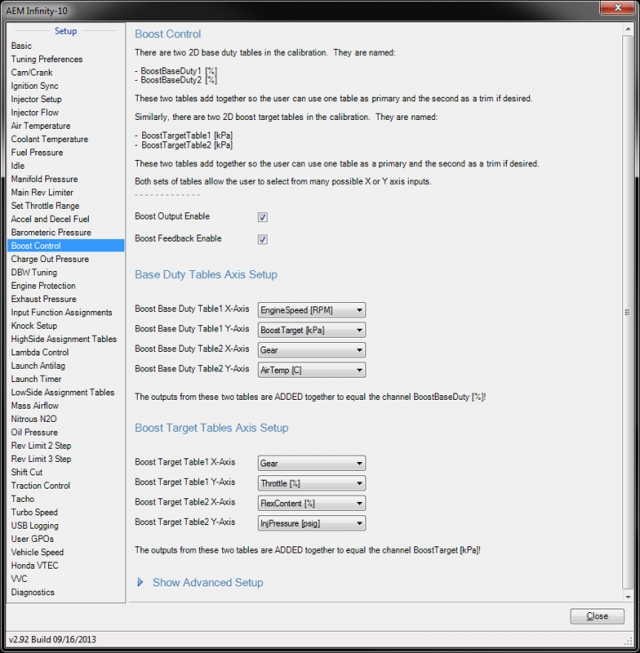

Boost control is achieved through a number of different strategies, including time, gear, vehicle speed, and switch-based, among others.

This capture of the boost control screen in the Infinity tuner shows all four boost tables. The X and Y axes for all four tables are user-selectable in the InfinityTuner software.

There are two 2-dimensional base duty tables and two 2-dimensional boost target tables. The secondary tables can be used as trims or adders. Users have the ability to choose from variables including IAT, MAP, barometric pressure, throttle percentage, flex fuel content, boost target, and more.

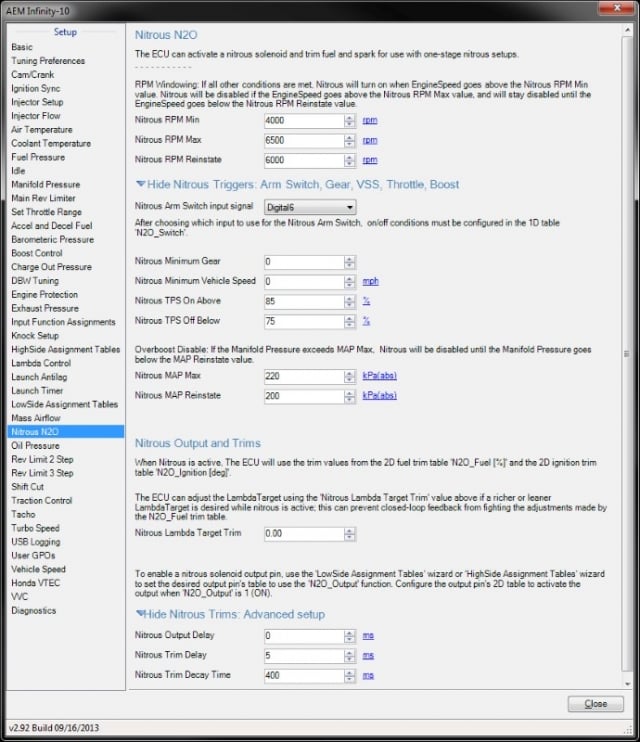

Nitrous control is also built into the Infinity ECU. Currently, the ability to run a single stage of either wet or dry nitrous injection is embedded into the system with a four-stage controller in the works for a future update. The nitrous controller includes fuel enrichment, ignition timing retard, and solenoid triggering. The user can set minimum gear, minimum vehicle speed, and TPS on and off percentages. There is also a built-in window switch that will activate the nitrous above a minimum RPM level, turn it off at a maximum level, and then reinstate it once the engine speed drops below the programmed Reinstate value. The feature can alternatively be set up for water/methanol injection tuning.

There are a ton of nitrous controls available in the software, and the ability to run four stages will be released soon in an upcoming software update.

Impressive wideband control

In addition, the InfinityTuner wizard allows the user to program the base duty, limit and variable-valve-control camshaft targets for up to four camshafts. It offers independent intake and exhaust cam position 2-dimensional target tables, with each camshaft controller activated by an independent closed-loop PID loop for accurate tracking.

Once you get past the initial building of the base file with the standalone, the sky’s the limit as far as power goes. – Ryne Cunningham, Cunningham Motorsports

Cunningham was also impressed with the closed-loop wideband control.

“It’s very fast and very accurate. In case you have a fuel pump failure, or let’s say the car’s going lean for whatever reason, the computer will compensate very quickly and allow you to save the engine, especially in a big-horsepower, forced-induction application,” he says. “It’s a safety feature and a consistency feature as well. Let’s say a guy is used to racing at sea level, then goes to a track like Bandimere that’s 5,000 feet up in the air, he’s going to have that air/fuel ratio stay consistent.”

There are multiple integrated engine protection strategies built into the Infinity ECU as well. A MAP-based limp mode uses an assumed pressure ratio table to compensate for pressure if a sensor fails or goes out of range. Overboost protection cuts the fuel until the boost pressure or throttle pressure decreases. Oil pressure, fuel pressure, coolant or oil temperature-dependent rev limit are also available for use with additional sensors, and knock control is offered with dual sensors that allow precision measurement of knock levels.

As many of the systems on the market command a specific air/fuel ratio, but have no feedback to determine what the ratio actually is, the Infinity has a leg up on the competition in this regard. The Infinity has a feedback loop controlled by a pair of internal wideband oxygen sensor controllers that allow intelligent control of the feedback, adding or subtracting fuel as necessary to meet the demands specified in the programming.

Here the team is checking out the VE table after a dyno run and making changes based on their findings.

Datalogging is also standard using one of two methods; FAT (File Allocation Table), which will support 10 channels at up to 1KHz, 20 channels at up to 500Hz, or 100 channels at up to 200Hz. Using the Infinity’s custom file system option (called RAW) allows the user to log up to 100 channels at 1KHz per channel using the included high performance 4GB USB flash drive. Though if you are looking for larger storage, AEM has successfully tested card sizes up to 64GB.

One of the advantages to using the RAW system is that if the memory chip is pulled, all data remains on the chip for viewing, instead of the loss of data that can occur with FAT datalogging if the chip is removed prematurely. However, one caveat to RAW logging is that it cannot be read by a standard PC – the chip must remain installed in the ECU and read from the PC through the ECU connection.

At the end of the day, Cunningham was very impressed with how easy the Infinity system was to operate in practice. Although the subject vehicle had an issue with the previously-installed boost controller, he’s looking forward to getting the car back into the shop to complete the tuning process. “I’m building a drag car myself and I’m strongly considering using this system based on my experience,” he says.