A racecar is built a lot like the human body: it has layers of systems that help it function and perform how it should at the track. One of the most important systems in the car is the plumbing that moves all of the fluids where they need to. Everything from your basic bracket car all the way to cutting-edge Top Fuel Dragsters need to be plumbed for adequate fluid transfer. Fragola Performance Systems [2] makes a wide range of products to assist with moving those fluids, and their Sport-Crimp fittings help make installing the plumbing in your car easier and more efficient.

Get In Where You Fit In: Fittings And Hoses

Fittings and hoses are things that are often overlooked on a build or project until it’s time to start the plumbing process. It can be easy to not take into account how complex the job might be or what kind of problems that will be encountered after everything is started, so it’s important to have a plan in place before you begin plumbing. AN-style fittings and custom hoses can be a great tool during a build because they allow the person doing the plumbing the freedom to build hoses as needed for the specific application according to their plan.

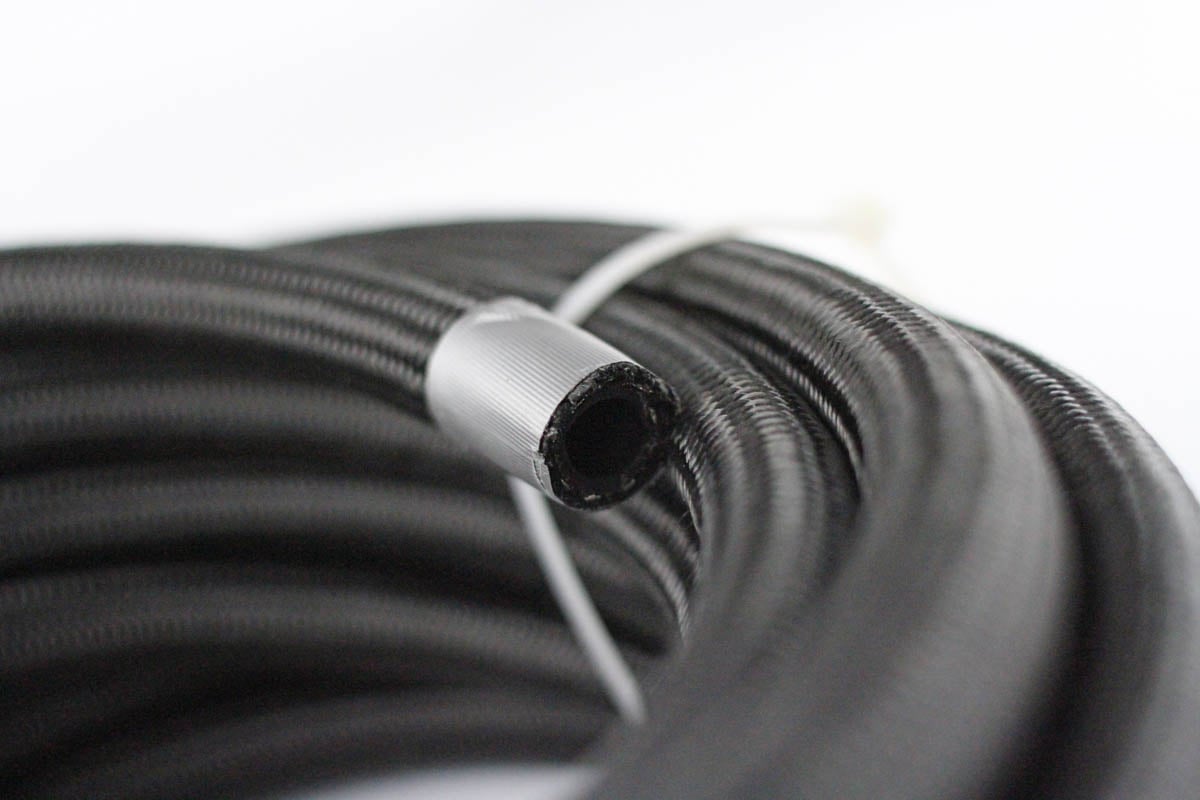

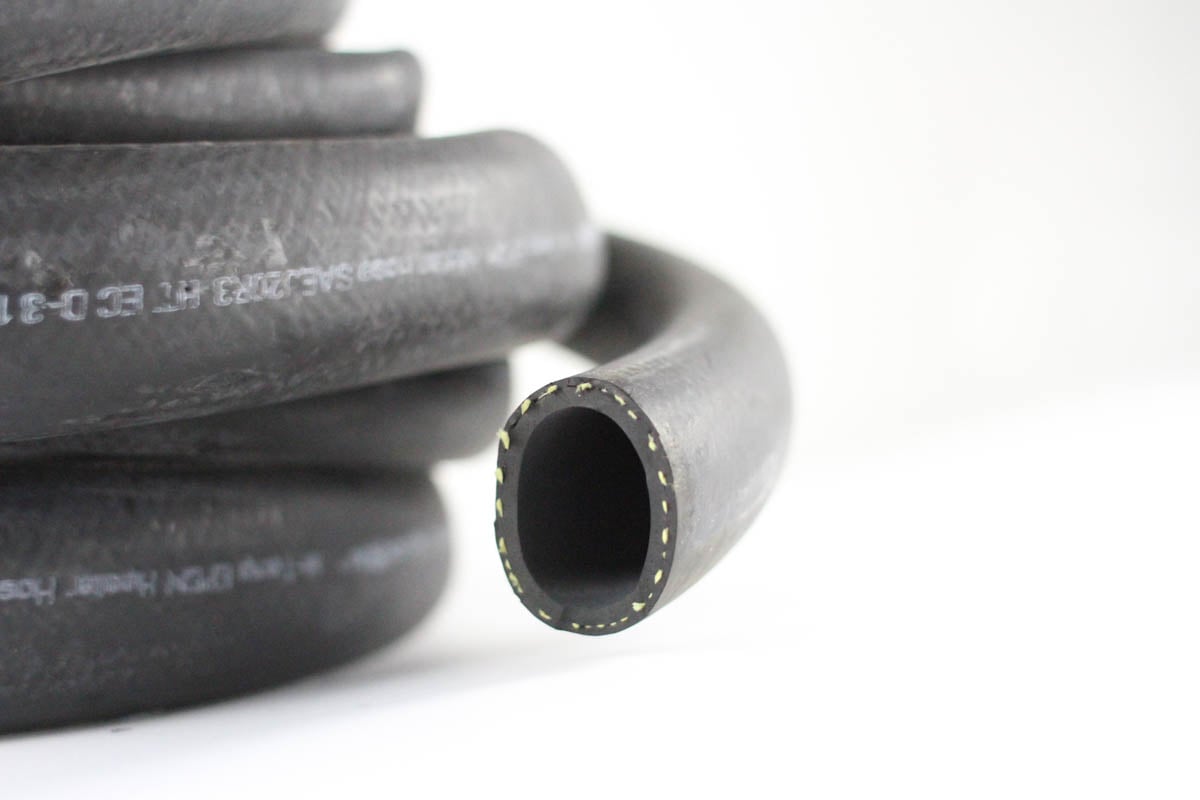

Using a quality hose is very important when plumbing a racecar to avoid any future issues such as cracks or leaks.

…be sure that the hose features the proper temperature, vacuum, and pressure ratings for the system you’re working on. -Brint McLellan

The nylon hose has a special C.P.E. synthetic rubber core that’s impervious to things like oil, fuel, coolant, and even alcohol, for up to 10 years. This style of hose has a working pressure limit of 350-500 psi depending on the size: more than enough to meet the needs of most racers that are building a fluid transfer system. It’s important to pay attention to the operating temperature range of these hoses so you avoid any possible failures, as well.

It's important to use a hose with the correct core for the type of fluid you will be transferring to help mitigate failures or leaks.

According to Fragola’s Brint McLellan, it’s ideal to go with the best hose possible for any high-performance plumbing project.

“I always recommend using the highest quality hose your budget will allow when plumbing your car. More to the point, be sure that the hose features the proper temperature, vacuum, and pressure ratings for the system you’re working on. This will keep it from failing and make the difference between doing the job once or multiple times over the years.”

AN fittings come in many different shapes, sizes, and styles to fit any application.

When you’ve selected the hose you want to use, it’s time to pick the correct hose ends for the application. These fittings are made of high-quality aluminum or stainless steel depending on the temperatures they will be subjected to. Most hose ends feature a female nut, but Fragola Performance Systems does offer a direct-fit product line that incorporates male pipe thread or O-ring adapters into their design.

Using direct-fit hose ends eliminates the need to run as many adapters, which keeps potential leak points to a minimum, cuts weight, and reduces the space needed to fit components. Hose end size will correspond with the appropriate hose size. Fragola Performance Systems offers hose from -3 (3/16-inch) through -20, (1-1/4-inch) that come in different angles to meet specific plumbing needs.

There are several methods of fitting the hose end to the hose. Fragola offers a few of these.

The first is the “cutter” method, which can be found on their 3000 Series hose ends. Here, the socket is tightened on the nipple, and the hose is drawn into the cutter, creating the seal. In their 2000 Series hose ends, they attach to the hose using what is known as the “single nipple” method. In this design, the socket is tightened down, and it draws the hose over an elongated single nipple that seals the hose to the fitting by crushing the hose in-between the inside of the socket and the outside of the nipple. Both styles are reusable and allow the user flexibility to make changes to their plumbing if necessary. Another option is the crimp-style fitting, which we’ll get into in a bit more detail later.

All fittings and hose ends aren’t created equal, so some serious thought must go into the choices you make for this vital part of your build.

“Many times, buying a higher quality hose end or adapter will save you time, money, and aggravation down the road over a lower-quality option. The higher quality ends tend to last longer and hold up to the rigors of being put on and taken off multiple times,” McLellan explains.

The Sport-Crimp Style Fitting

Reuseable style AN fittings have been around since World War II when they were first introduced as a solution to meet the military’s needs for a high-quality fitting to use in aviation applications. The fittings worked well with the various hoses on aircraft and eventually found their way into the plumbing of high-performance cars. The one major downfall to the reusable-style fittings is the time and effort it takes to assemble them. Crimp-style fittings have been the answer to the time issue and make fabricating runs of hose on a racecar much easier.

(Far left) To build a hose with the Sport-Crimp fitting you first cut it to length, then put the crimp collar on. (Second from left) You then insert the fitting into the hose and collar. The crimping process begins by using the appropriate die for the hose that you’re working on. (Third from left) You then put the hose through the die before you go to begin the crimping process. (Far right) There’s a cone that comes down that puts pressure on the sides of the die and that’s what actually performs the crimp to whatever specification you need.

The Sport-Crimp fitting from Fragola is a simpler way to make any size hose when you’re plumbing a racecar. The hose is inserted over the nipple of the fitting, and the collar is crimped over the hose to create a leak-proof seal. “The ends make it a lot quicker and easier for just about any application, and that’s the real draw to use them with any style hose. You don’t have to use aluminum vice jaws, wrenches, and everything else that’s part of the process when you make the hoses with the reusable fittings,” McLellan explains.

Fragola’s Sport-Crimp ends are made from high-quality 6061-T6 aluminum. The fittings are made with a one-piece tube design that are a mandrel bent, therefore eliminating a joint that’s brazed together. By using the mandrel bend-style, it makes the fitting much stronger overall, minimizes any leak threats and helps the fitting flow better. Inside the fitting, a pair of Vitron O-rings are used to create a seal that keeps fluids inside the fitting, and can’t be damaged by oil, fuel, or coolant.

Tips For Crimping

McLellan offers some great advice on how to get perfect crimps every time. “You want to make sure you’re using the correct die set for the crimp you’re trying to perform. If you use one that’s either too large or too small you end up getting really large parting lines on the crimp collar, so you won’t have a full contact patch. You really want as much contact between the hose and collar as possible so it’s very important to have this done correctly, otherwise, you will have leaks and failures with the hose.”

According to McLellan, there’s a good reason the Sport-Crimp fittings are so close to the 2000 Series hose ends.

“We’ve designed our Sport-Crimp fittings to be almost identical to our 2000 Series Reusable fittings to help keep the cost down. By keeping these fittings the same as the 2000 Series, we were able to limit our tooling costs and pass some of that savings to the end-user. They can be used on our Black Nylon Race Hose or 3000 Series Stainless Steel Hose, so you don’t need to invest in different hoses if you decide to switch to the Sport-Crimp fittings.”

Applications And Advantages Of Sport-Crimp Fittings

Plumbing a racecar can require creative solutions on how hoses are routed and fittings are used, depending on the situation. The Sport-Crimp fittings are a product that can be used in a variety of applications just like a standard reusable AN fitting, and that makes them useful on any build. Fragola has worked hard on making sure the Sport-Crimp fittings can do just about any job the end user needs them to do.

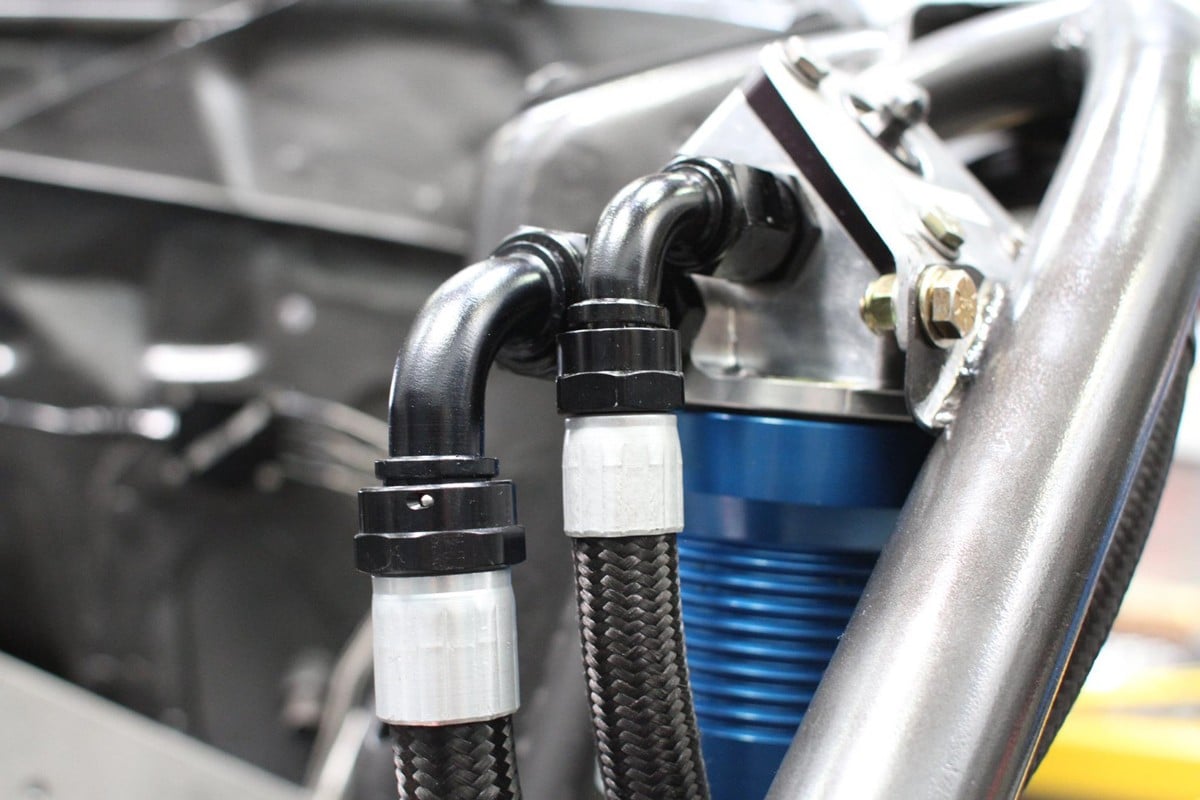

Sport-Crimp fittings can be used in many different locations on any build and will speed up the hose making process for any project.

The Sport-Crimp fittings are just as good as the reusable ends in regards to leakage (or lack thereof, rather), but the convenience and ease of making the crimp ends are what pushes them to be the best choice for high-end applications. “I tend to recommend this particular product segment to customers who are planning to use reusable hose ends but want to take their build to the next level. This fitting is also a great application for shops that will be doing a lot of plumbing and hose assembly in-house, because of the time savings they offer,” McLellan says.

[21]

[21]Here’s an example of a racecar that would benefit from the weight savings and convenience of the Sport-Crimp fittings.

I tend to recommend [Sport-Crimp fittings] to customers who are planning to use reusable hose ends but want to take their build to the next level. -Brint McLellan

“Used with our Black Nylon Race Hose or 3000 Series Stainless hose, our Sport-crimp hose ends are a great choice for plumbing your racecar’s dry sump, fuel system, intercooler, or coolant lines. With the crimp machine and the correct dies, you can even make nitrous lines, brake lines, and PTFE hose. These ends can also work with high-pressure systems like power steering lines,” McLellan explains.

The fittings offer more than just good looks; they can save time and make the plumbing process easier. “A lot of shops make the switch to our Sport-Crimp hose ends to speed up the assembly process. Hoses can be mocked up on a car, taken off, and brought over to the crimp machine to complete the installation process. No more fooling around with aluminum vise jaws, AN wrenches, and having to be careful not to mar or scratch the finish on new parts,” McLellan says.

(Left) Making the reusable-style hose ends seems prehistoric and cumbersome compared to using the (Right) Sport-Crimp system with its clean crimping machine.

Another advantage the fittings offer is their weight savings when used in conjunction with the correct hose package. If you think about it, there are a lot of hoses and fittings on your typical racecar and their weight can add up in a hurry. Being able to save upwards of 15 pounds in just fittings and hoses would allow a racer to put that weight to better use in the car for ballast (or just be lighter and quicker). “Typically, the crimp-on ends are about a tenth of a pound lighter per hose than their 2000 Series reusable counterpart. I recommend using these ends with our black nylon race hose, so you can get the maximum weight savings possible as you plumb the different systems on the car,” McLellan explains.

Here are just a few of the locations we used the Sport-Crimp fittings on our Evil 8.5 project car to help save weight.

We’re using the Sport-Crimp fittings on our Evil 8.5 project car [28] and did some weight comparisons to see exactly how much was saved between the reusable fittings versus the Sport-Crimp fittings. Below is a table showing how much weight was saved just in fittings alone for AN fitting sizes that are very common on most racecar builds. As you can see, the ounces start to add up quickly, and when you factor in using a lighter weight hose, it becomes easy to shed weight in a car.

-16AN -12AN -10AN -8AN

Sport Crimp: 2.7 C: 2.0 C: 1.2 C: 0.9

Reusable: 4.8 R: 3.0 R: 1.9 R: 1.4

Difference (in oz.): -2.1 D: -1.0 D: -0.7 D: -0.5

Using higher quality fittings and hoses to plumb your racecar has many benefits that will make the car function better and save weight. Fragola’s [2] Sport-Crimp fittings are a product that will help save time on your build, and when used with a quality hose, will save weight in key areas of the car. When it comes time to plumb your next project, make sure you put some thought into the process and consider using Sport-Crimp fittings to make the job easier.