It’s no mystery that Pontiac GTOs had horrible brake systems from the factory. While the engines were very high performance, the brakes were not – especially true in the early GTOs. The Delco-Moraine drum brakes were the standard at the time, but woefully inadequate for spirited drivers and downright dangerous for those attempting to push the boundaries in road racing.

Brake system selection was one of the early decisions we had to make when working with Jeff Schwartz for the Project Payback car chassis build. Schwartz Performance offers a couple of different brake systems at the factory. We’ll discuss these in detail later. In order to create a better-balanced performance road racer, we tapped into the experts at Baer Brakes and Jeff Schwartz to help refine a system that would work well with our Schwartz Chassis and Moser full-floating Moser 9-inch rearend.

History Lesson: Pontiac GTO Brakes 101

In 1964, the first Pontiac GTOs were available as an option package for the Pontiac LeMans, often referred to as the “Grand Tempest Option.” Like many other systems in the GTO, the new line was equipped with a brake system that was identical to the Tempest. As mentioned in the intro, this brake system was lacking, even during those times. The four-wheel drum brakes with organic linings were ill-suited for high-speed driving. The semi-metallic brake linings were better, but not by much.

Front disc brakes were offered as an option in 1967 in response to a federal regulation aimed at car safety. Disc brakes have always been a major improvement but few cars were sold with this option to the public. The most significant improvement due to the regulation was the addition of a dual-chambered master cylinder that would prevent total brake loss if a brake line broke.

The 1960s era Pontiac GTO brakes were horrible compared to the performance offered under the hood. There was lots of go, but not a lot of whoa when it came to stopping. It wasn’t a matter of “repair or replace” for us. We were going to upgrade the brakes without hesitation.

In 1968, the four-piston disc brake option was carried over from 1967, but most of the 1968 models that made it to the streets had drum brakes all around. In short, the GTOs were getting more powerful and heavier but the brakes were not improving. These days, it is not a question of repairing or replacing when it comes to GTO restoration. It is simply a matter of which aftermarket kit should replace the stock brake system during a rebuild.

What Schwarz Offers At The Factory

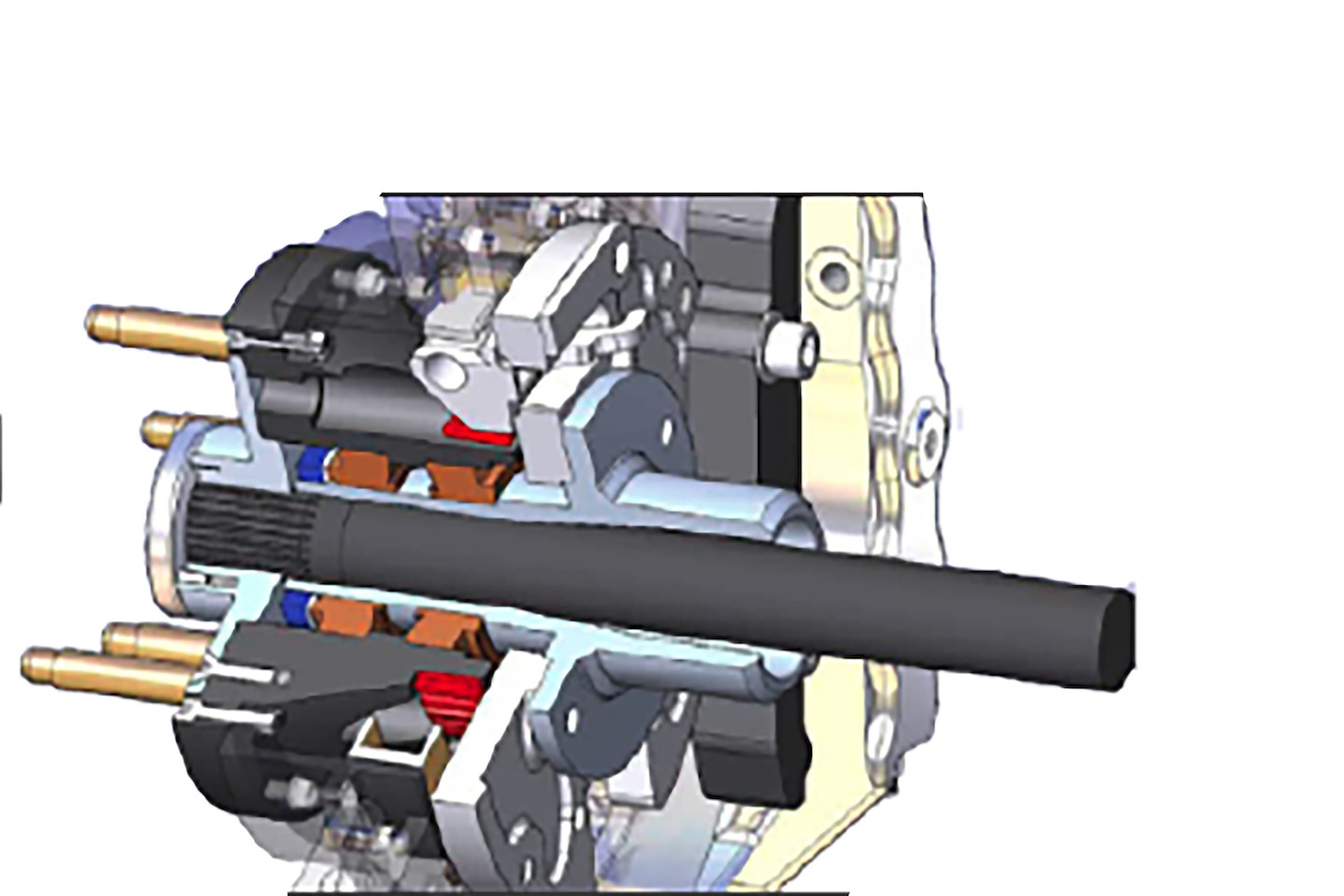

When it comes to brake systems, they are generally divided into sliding (floating) caliper and fixed caliper. As the name implies, a fixed caliper is solidly mounted and can apply more clamping power. Not only does the fixed caliper brake provide more clamping power, but it also provides the clamping power more evenly to both sides of the rotor.

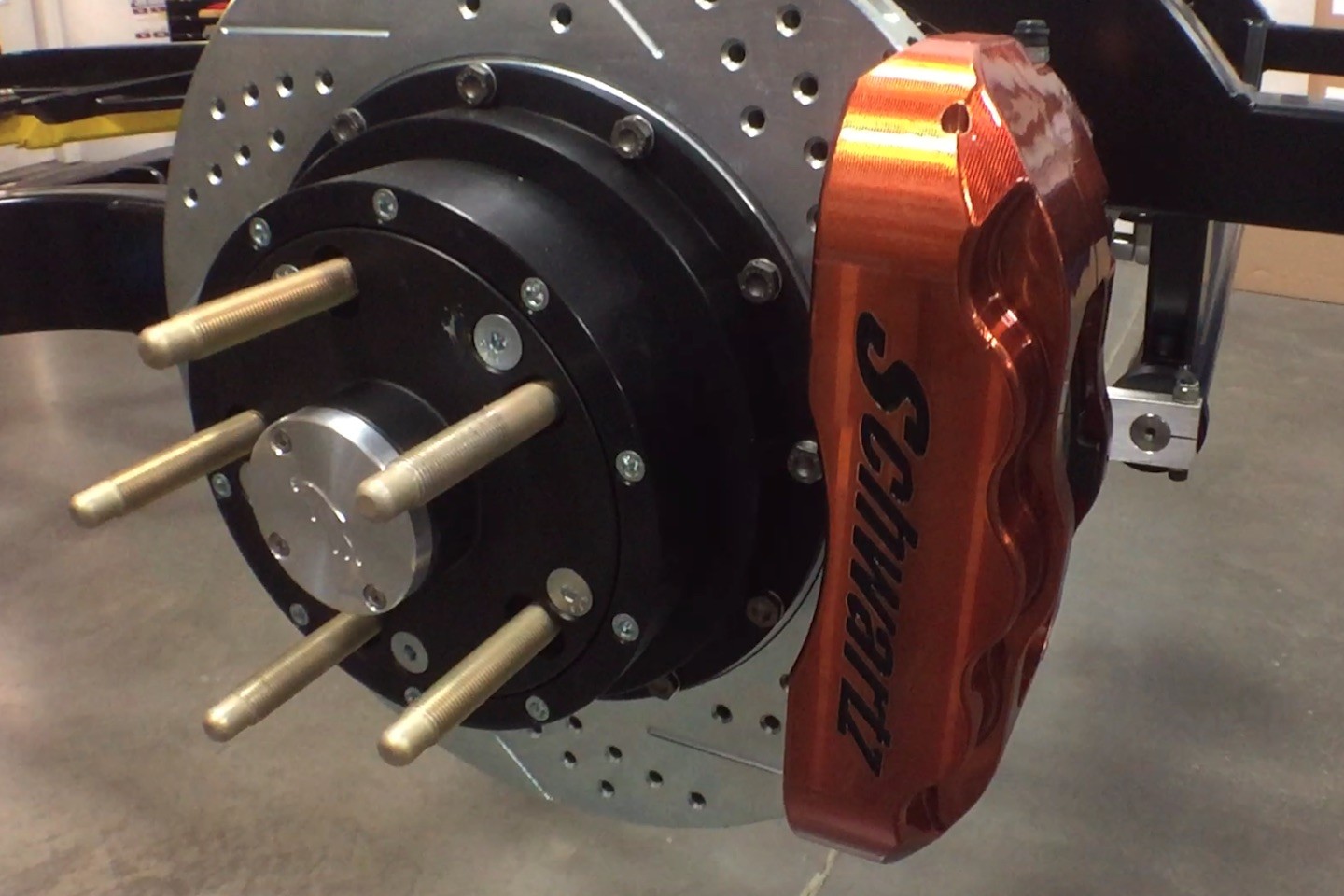

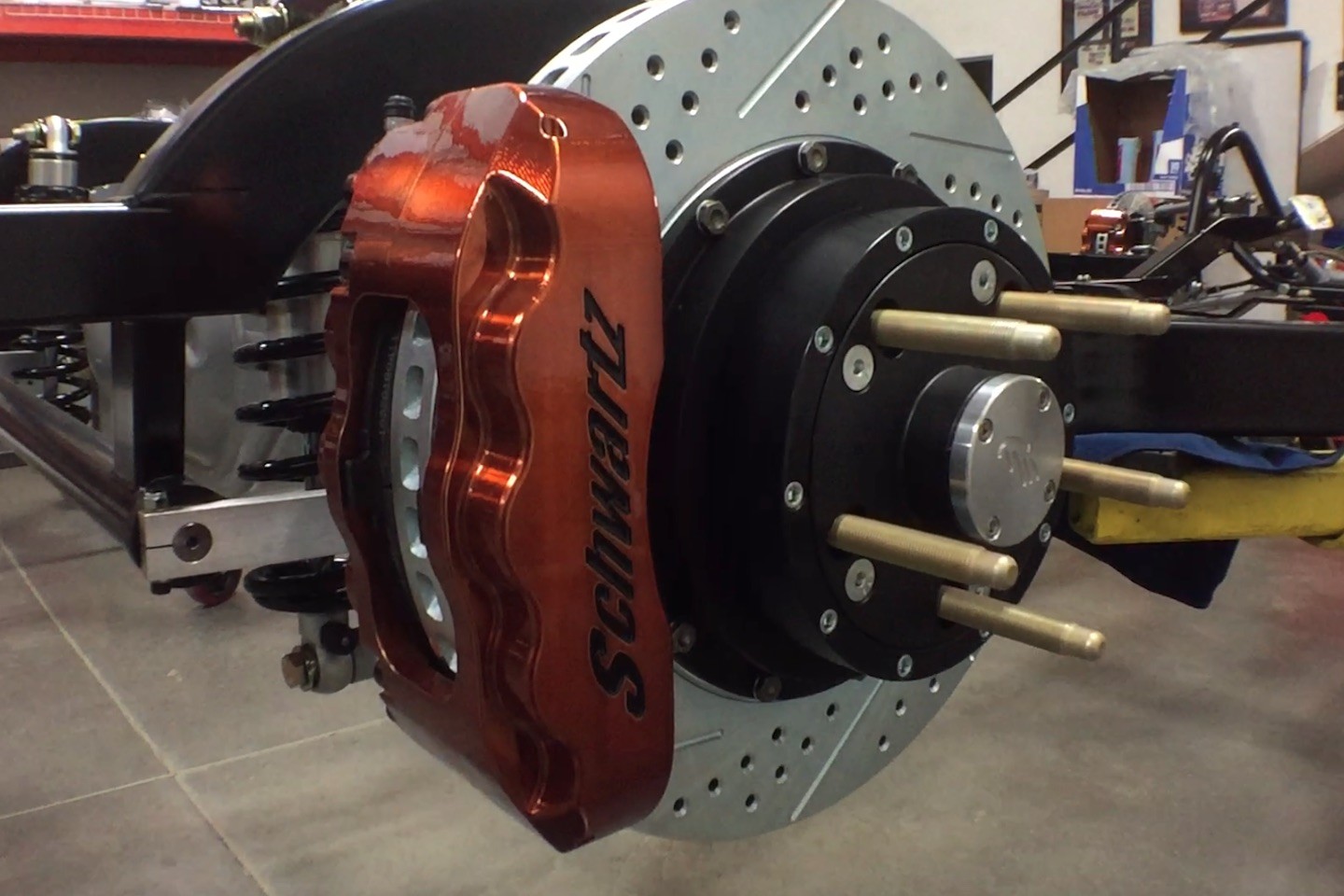

Schwartz Performance offers three different brake options for the GM A-body chassis. Two of these brake systems are manufactured by Baer Brakes for Schwartz Performance. We opted to go with the top of the line for safety and performance.

The fixed caliper uses multiple pistons that are sorted in pairs of two, four, and six as opposed to the sliding or floating type caliper which uses a single-piston. This gives the fixed caliper brakes a better feel through the brake pedal which is preferable in performance vehicles. Schwartz Performance offers three different brake systems for this chassis at the factory.

Starting with a 13” Wilwood kit that is designed for daily drivers and occasional autocrossers/road racers. This setup requires a 16” diameter wheel. However, some 15” wheels will work but plan on having to pick up a set of 16’s just to be safe. The Wilwood brake package from Schwartz feature 12.88” rotors and six-piston calipers front and 12” rotors with four-piston calipers in the rear for a nicely balanced brake kit. The calipers are finished in a black powder coat. The rotors are available in slotted only or in cross-drilled and slotted engineering designs.

The next step up in Schwartz’s brake options is the 14” Baer 6P Pro-Plus system. “This is a brake system that will suit whatever you want to do,” said Schwartz. It is at home on the street, at an autocross event, Pro Touring, and can handle road racing without a problem. The Baer 6P kit rotors are cross-drilled for cooling and cleaning.

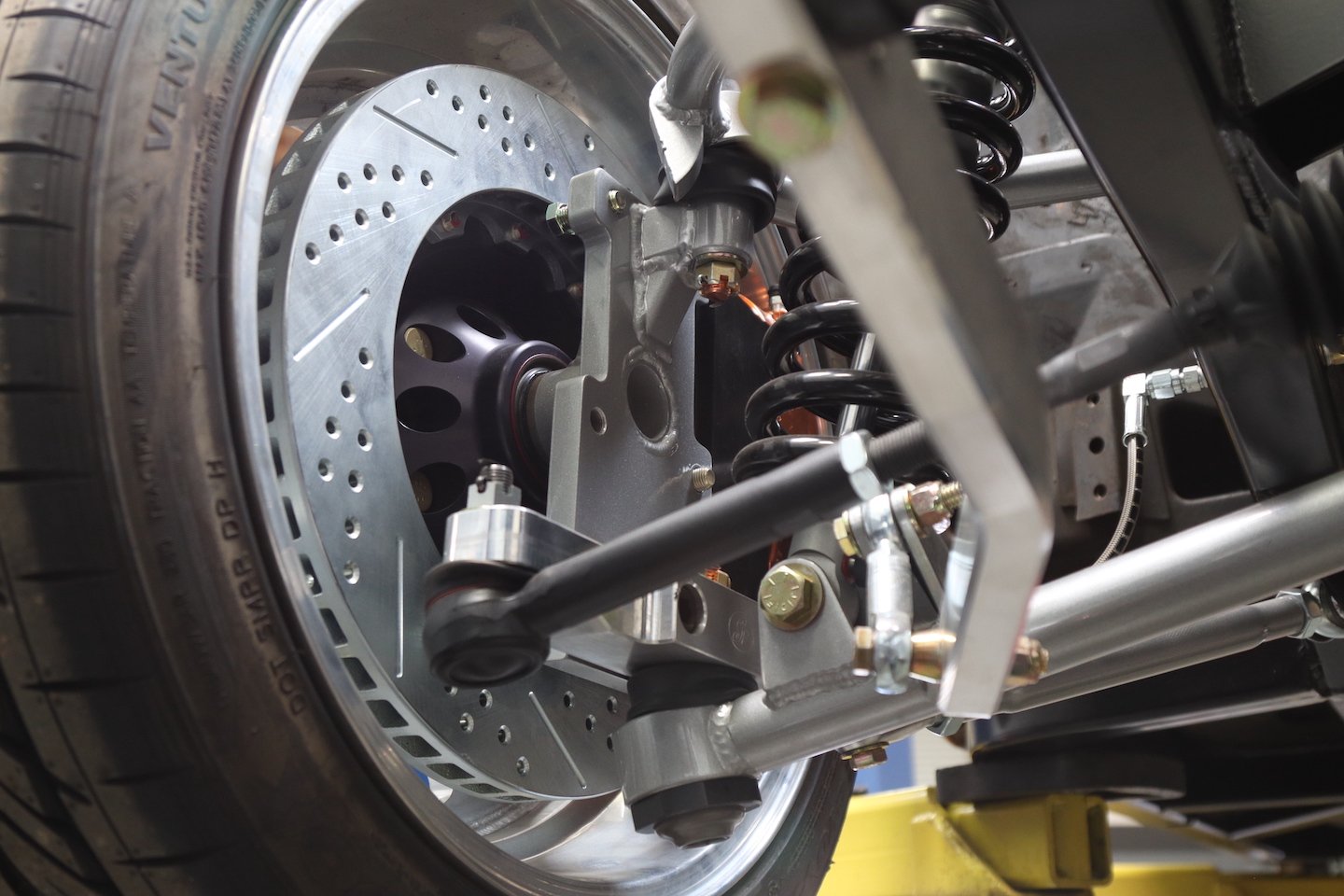

The front calipers and rotors fit into the chassis and wheel nicely. With larger wheels and tires that grip the asphalt extremely well, we knew that the leverage on the rearend was going to be high.

The top of the line brake kit in the Schwartz arsenal for the GM A-body chassis is the Baer 6S brake kit which is a one-piece forged caliper. “This brake kit suits the hardcore roadracer but does not sacrifice street driving. However, the 14-inch brakes require an 18-inch diameter wheel,” Schwartz added. The Baer calipers are available in many colors for those builders looking for color matching. The Baer 6S 14” rotors are also cross-drilled for performance.

Traditional Axles Kick Back Problem

Our goal with this build is to push the GTO hard in road racing and autocross events, so we decided to go with a Baer Brakes setup from Schwartz. “The Baer 6 piston calipers have a slightly smaller piston diameter so the proportioning is proper,” said Schwartz. “Our chassis comes standard with a full-floating rearend. The one in this project car is a Moser full-floater with Baer floating hubs on it.”

Keeping in mind the goal of this entire build is to bring race car technology to the street, going with a full-floating rearend was a no-brainer. A full-floating rearend handles side loading better during hard cornering. Traditional flanged-axles tend to experience axle deflection when exposed to lateral forces. The problem becomes worse with higher cornering speeds, and we fully intend on using higher cornering speeds.

Traditional axle’s deflection “kicks back” or pushes the pads into the pistons, which forces the pistons back into the caliper. The pistons stay in the caliper which creates space between the rotor and the brake pads. This space is felt by the driver as he steps on the brake pedal as dead space until the pistons are pushed out far enough to force the pads to contact the rotor. The brake pad kickback problem is exacerbated by larger, tackier wheels which increases the leverage effect.

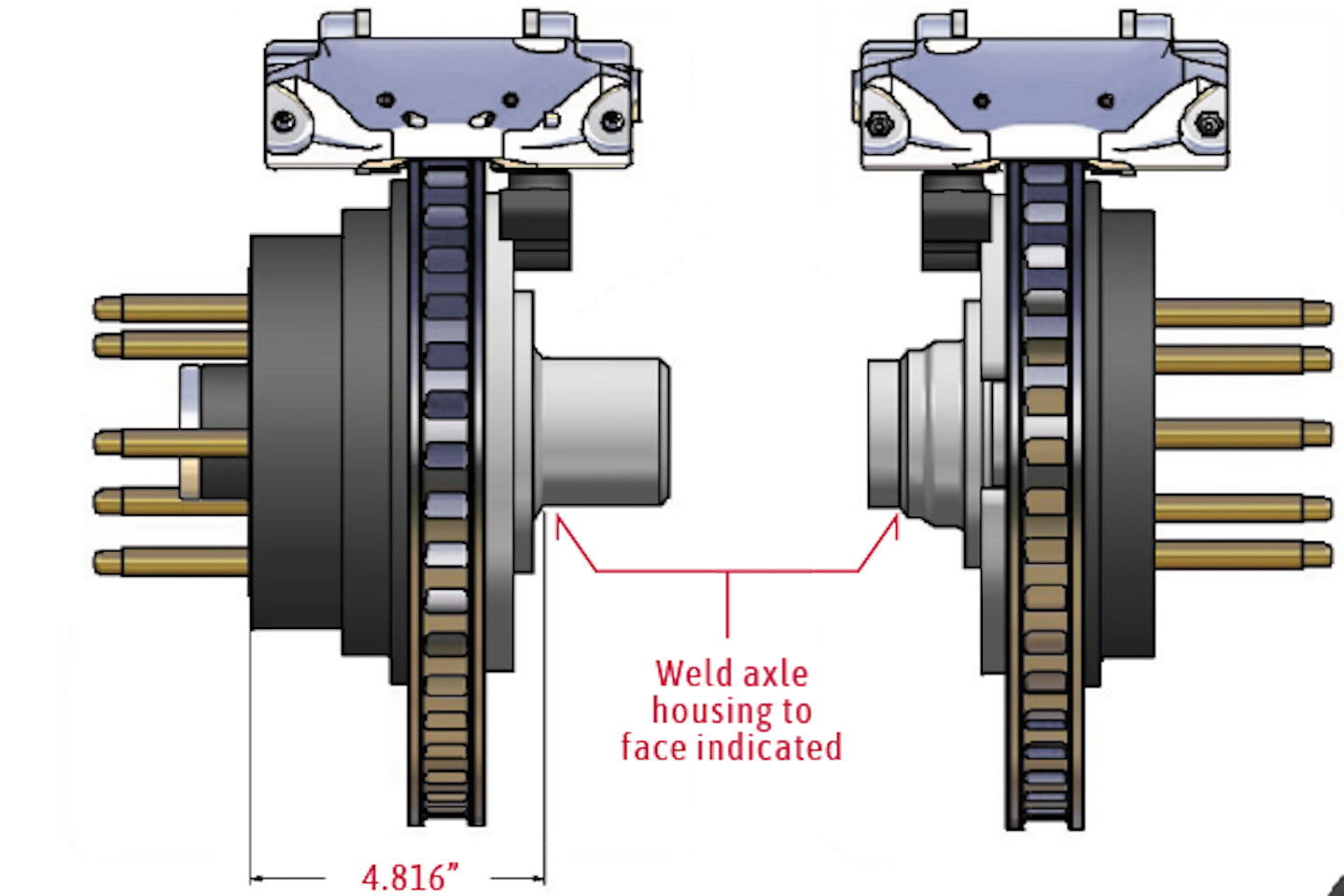

The snouts have to be welded onto the axle housings so the conversion is not something you can easily do in your home garage. This operation is best left to professionals like Jeff Schwartz.

Converting to a full-floating rearend will prevent that kick-back which allows the system to take full advantage of the fixed calipers without the pulsing or dead space feel in the brake pedal. In addition, the constant deflection of traditional axles decreases bearing life. Changing to a floater rearend will add longevity to the components. To sum it up: Fixed caliper brakes and full-floating rearend should be used when more powerful braking and dependability are a priority over low cost.

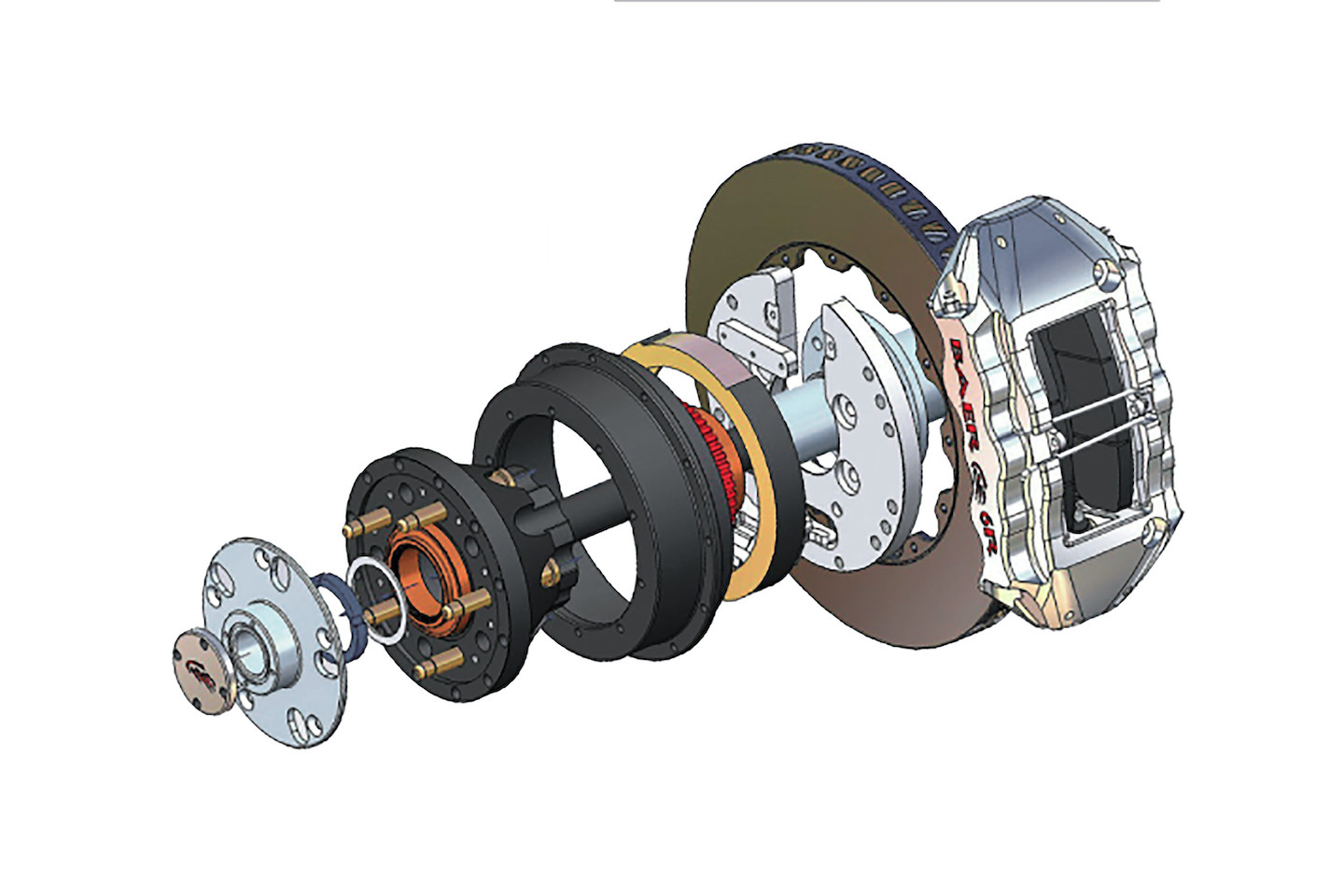

A floating axle does not rely on a flange and a bearing to position and drive the wheels. As seen in this illustration, the axle goes straight through the hub and splines into a drive plate. This setup allows the axle to move along the splines as needed.

Baer Brakes Full Floating Axle Conversion

“To be clear,” said Baer Brakes’ Tim King, “The Tracker Full Floating Axle Conversion System is purchased as an upgrade to a variety of our brake systems.” Not a stand-alone kit but certainly one that is needed to refine floater axles for the Pro-Touring market. “When the Tracker conversion system is purchased it does not include any brake parts, just the parts needed for the floater conversion,” King added. “And is 100 percent USA built.”

Features And Benefits Of Tracker Full Floating Axle Conversion

- A narrower footprint than traditional floater designs.

- Smaller register to fit street-type wheels.

- Standard car stud patterns (5X4.75” and 5X4.5”).

- Fully ABS compatible with Ford and GM configurations.

- Drive plates built by Speedway Engineering specifically for Baer that uses a 24-spline arrangement based on NASCAR specs. Baer’s 24-spline drive plate is .050” larger than a standard 35 spline axle.

- ARP 1/2” X20 race studs.

- Dramatically improved handling through predictable and consistent brake pedal height and tire contact patch.

- Longer service intervals on rotational parts, bearings, and axles.

- First floating axle conversion with fully integrated park brake assembly (1-piece shoe design has 35-percent greater break-away-torque than conventional 2-piece shoe configurations).

- Fully ABS compatible.

The conversion process includes removing an additional 0.640” from the axle tube in order to maintain wheel location. The tube’s snout has a machined flange to allow systems with late-model big Ford ends – commonly referred to as Torino ends – to bolt onto the snout. Once the snout is installed, this is a complete bolt-on with no need to weld brake brackets onto the rear end. If you have an existing brake system with a backing plate other than Torino, new backing plates will need to be ordered.

For more information on Baer Brakes Tracker Full Floating Axle Conversion, go here. For Baer Brakes calipers and other braking components visit Baer Brakes online at baer.com. For more information on Schwartz chassis visit them online at www.schwartzperformance.com. For information on Moser rearends, visit Moser Engineering online at www.moserengineering.com.