Heat control and protection should always be a priority for any high-performance build. Parts can be damaged from both direct contact with a hot surface, or through prolonged exposure to heat. Anything you can do to protect electronics, wires, or fluids under the hood of your vehicle from heat is important.

We worked with Design Engineering Inc. (DEI) on Project Number Cruncher and Project Red Dragon to come up with a heat control plan for each vehicle. In this article, we’re going to cover some of the DEI products we used, and why we used them, with Steve Garrett from DEI.

DEI's turbo blankets are available in multiple sizes for different turbos.

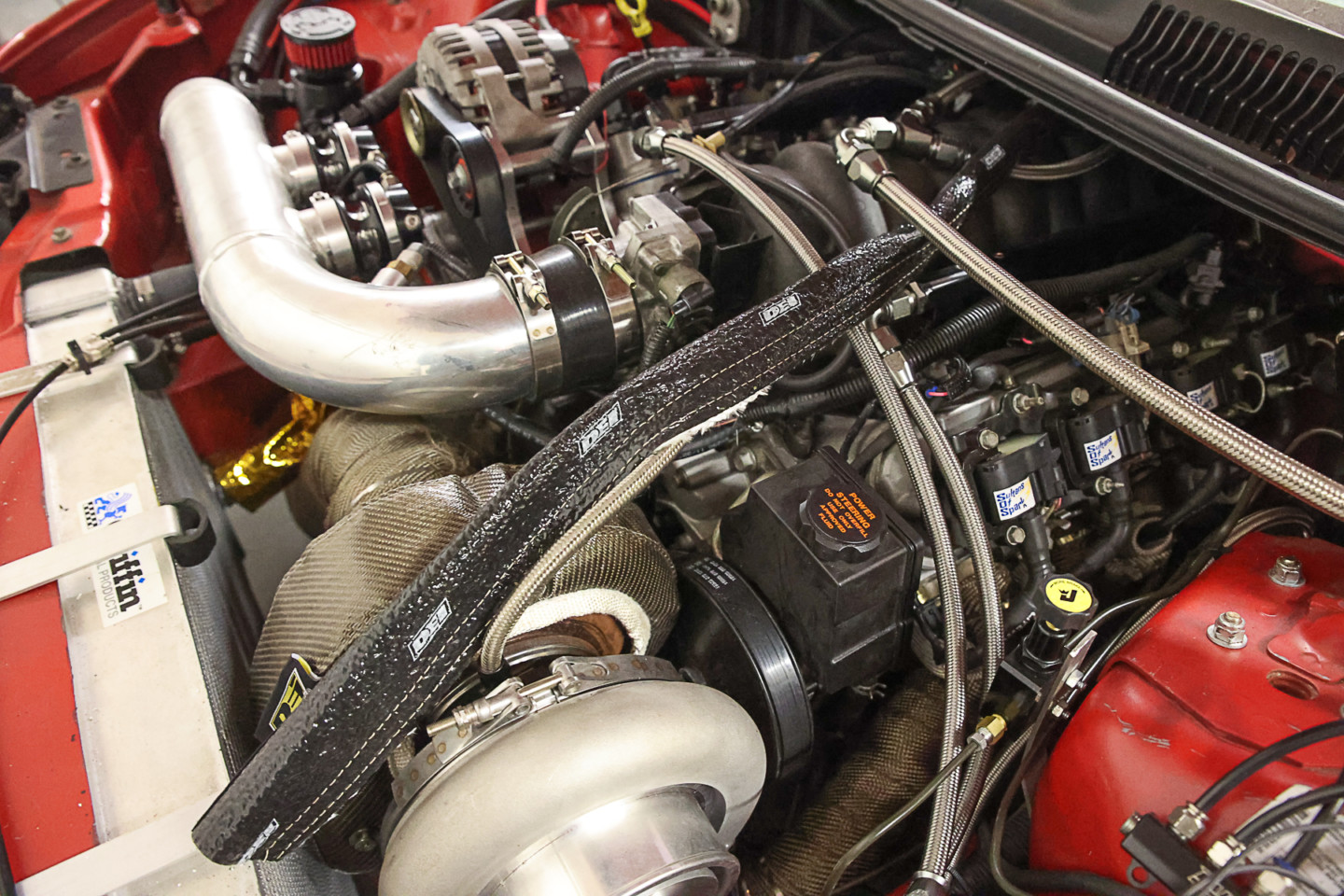

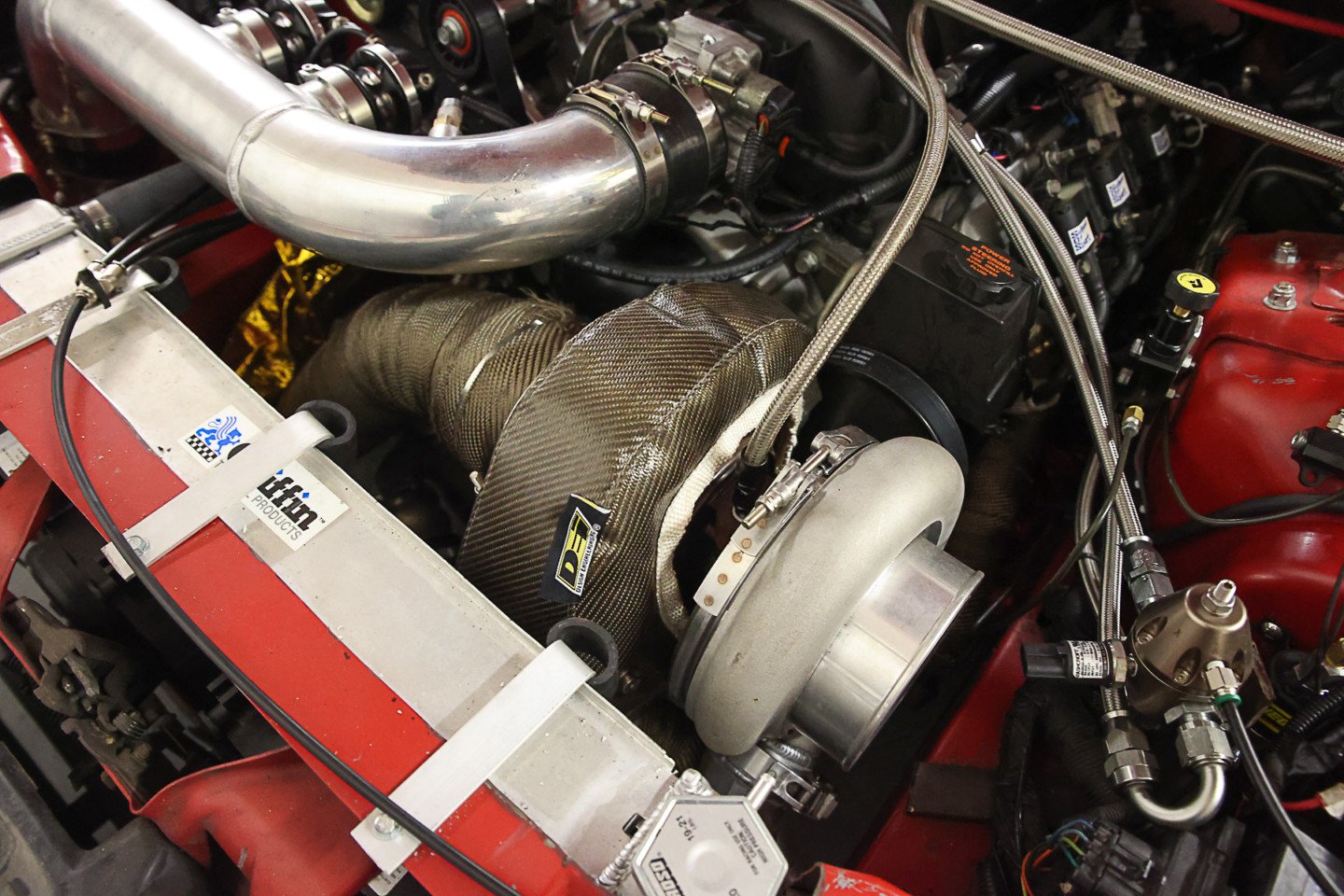

Keeping Turbo Heat In Check

Now that we’ve swapped Project Red Dragon’s nitrous system for a turbo kit, it was time to limit the amount of radiant heat the turbo could produce. The 80mm VS Racing turbo is going to make plenty of horsepower, but it’s also going to crank out some serious heat. A quality turbo blanket is the only way to fight the heat a turbo can generate under the hood of a vehicle.

A turbo blanket is going to help reduce intake temperatures, as it lowers the amount of heat that can soak into the intake and charge pipes. The turbo blanket is also going to protect all of the electronics that might be close by, as well as any wires or fluid lines from intense heat. According to Garrett, the turbo blanket holds heat in the turbo, therefore, it helps the turbo spool faster and become more efficient.

Turbos can generate a punishing amount of heat under the hood of your vehicle. A turbo blanket will help control the temperatures your vehicle’s critical parts and systems are exposed to.

We opted to use one of DEI’s GEN-3 turbo blankets on Project Red Dragon’s turbocharger. Garrett provides some details on how you can get the most out of a turbo blanket, and how to properly install them.

“Make sure you have the proper size blanket for your turbo. You need to ensure the turbo is covered as much as possible; you also need to make sure the blanket is secure. You’ll want to use some heavy gauge metal wire or a spring to tie it down around the riveted tie-downs to hold it in place.”

Properly Protecting Plug Wires

Spark plug wires can easily fall victim to heat damage when they touch your headers. The heat that headers put out can also impact how well the spark plug wires will perform. We knew that since Project Red Dragon was getting a turbo kit from Huron Speed, that some form of plug wire protection was needed. What we didn’t realize was Project Number Cruncher’s spark plug wires would need some heat shielding, as well. We turned to DEI and added one of its spark plug wire protector kits to Project Number Cruncher.

DEI's plug wire protectors are designed to deal with the heat created by headers.

If you’re still on the fence about adding some spark plug wire protection to your wires, Garrett stressed to us why it’s a good idea.

“Headers can route differently than stock manifolds, and that can allow plug boots and wires to come really close to the tubes. Spark plug wire protectors prevent plug boot and wire burn-through if they happen to touch the headers. This is important, because if the wires are damaged, they could possibly arc and hurt engine performance. The spark plugs wire protectors also allow you to pull the plug boots and wires off the spark plugs by giving you a firm grasp on the plug wire/boot.”

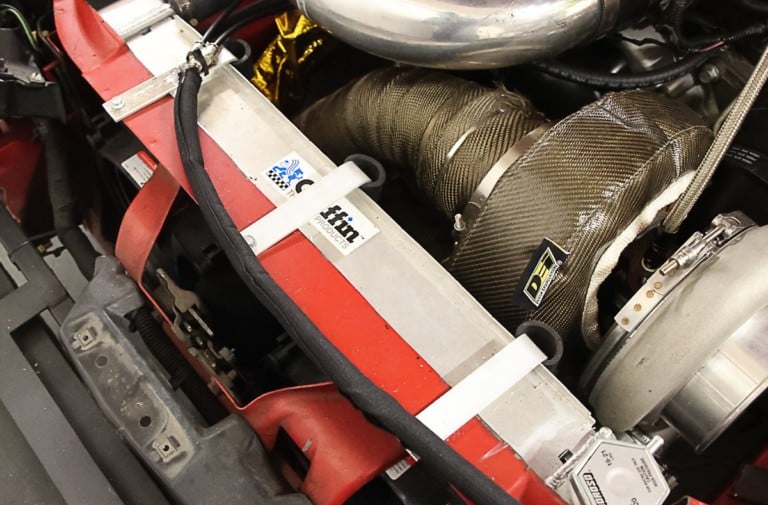

DEI includes everything you need in its Easy Loom Master Kit, including a tool to hold the wire loom open as you’re wrapping it around wires.

Cleaning Up and Protecting Wiring

Wiring issues can take you out of a race just as easily as a major parts failure. One of the easiest ways to prevent wires from being damaged is to not let them roam free under the hood of your vehicle. Not only will using a product like DEI’s Easy Loom protect your wiring from heat, but it will also make it easier to troubleshoot any electrical issues you might run into. Plus, it will just look nicer under the hood without seeing random wires everywhere.

The Easy Loom split-line sleeve was the perfect choice for both of our vehicles, since it can withstand temperatures up to 345 degrees Fahrenheit. Easy loom is also resistant to most automotive fluids and chemicals, so it won’t break down if you get a little brake cleaner on it. The self-closing design has a built-in 30-percent overlap, so it really wraps up your wires.

The Easy Loom is perfect for wires and hoses like our boost controller's plumbing.

Garrett provides some tips on how to get the most out of DEI’s Easy Loom and how to make using it easier.

“One tip is to use the installation tool included with the master Easy Loom kit. Longer wires can be a challenge to place inside of a split sleeve — the tool is designed to hold open the sleeve while wires are easily inserted inside the sleeve. Another tip is you can pull individual wires out of the sleeve as needed to run them to a specific location if you have a long run of wires inside the sleeve.”

Easy Loom is great for cleaning up and organizing wiring, but it has a limited amount of heat resistance. If you need something to provide real heat protection for wires and hoses, DEI’s Fire Wrap 3000 is perfect. Fire Wrap 3000 is very flexible and can withstand 500 degrees Fahrenheit of direct heat, and upwards of 2,000 degrees Fahrenheit of intermittent heat.

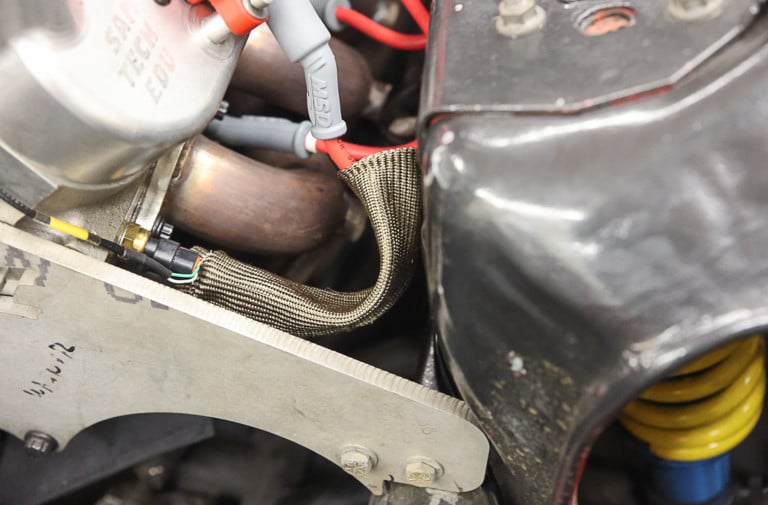

Since Fire Wrap 3000 uses a split design, you don’t have to disconnect anything you’re trying to place inside the protective sleeve. Fire Wrap 3000 is easy to cut, and it’s flexible enough to fit around tight bends. We used it in numerous locations on both cars to protect the wiring for O2 sensors, cooling system hoses, and other items in the engine bay.

You can wrap the Fire Wrap 3000 around whatever you want to protect.

“Fire Wrap 3000 is made of thick glass-fiber insulation, and it helps prevent heat-soak into lines that are close to a heat source. The thick silicone coating on the outside of the wrap protects against abrasions and wear on hoses and wires. Fire Wrap 3000 can help with ruptured fluid lines, too. We’ve had racers rupture fuel, brake, and oil lines in a crash, and the Fire Wrap 3000 has helped contain the fluids,” Garrett states.

When you’re working on a build or are planning a new one, make sure you account for some type of heat control and protection. Not only will using the right heat control products help extend the life of critical components, but it will also increase performance and improve the reliability of important vehicle systems, too.