When it comes to ignition systems, we’ve come a long ways since the days of distributors, points, and vacuum operated advances. These days, we’ve got coil-near-plug systems that are capable of delivering high-voltage spark to each plug, eliminating the need for one coil to handle the duty of firing all eight cylinders. And while the stock coils of today are lightyears ahead of the ignition systems of yesteryear, there are still improvements to be had when replacing your stock coils with something that packs a little more punch.

As you may be aware, Project C700 is our resident C7 Corvette that we originally set out with the goal of making 700 crank horsepower. We started by installing simple bolt-ons, such as headers and full exhaust and eventually made the step up to a little boost with ProCharger’s i-1 system. That brought our output to just within site of hitting our goal. But something was missing. With increased boost pressures comes the increased propensity for spark blow out, which is where the boost pressures are actually high enough to impede spark transfer from the plug’s electrode to the ground strap. With that in mind, we turned to Granatelli for a set of their Malevolent 85,000 volt ignition coils (PN 28-0514-CPM) and spark plug wires (PN 28-1545HTBB) to help put us over our power goal and ensure that our spark was strong enough for even the highest boost levels.

Before we dive into the coils themselves and the install, lets take a look at coil construction and why modern ignition systems are so much more advanced than their forebears.

Operation

While the operation of a coil may seem simple, there are many complex factors that contribute to the components overall goal of creating spark and igniting the air-fuel mixture inside the combustion chamber. Even though coil-near-plug systems are relatively new, ignition coils have been around for decades; and though the systems that control them may have advanced greatly over the years, the standard operating principles behind them are roughly the same.

Coils are essentially transformers — meaning they amplify or transfer electrical energy from one circuit to another using inductively coupled conductors. A coil is typically constructed out of an iron core surrounded by two sets of wound wire typically referred to as the primary and secondary windings.

The primary windings are typically much thicker in diameter than the secondary windings. Due to the dimensions of the wire, there are more windings in the secondary set than in the primary; by up to as much as 10 times — and even more in performance applications. In essence, the more secondary windings there are in comparison to primary windings, the higher the spark voltage it will be capable of producing. The primary and secondary windings are insulated from one another and do not touch.

The primary windings have a very low resistance, typically less than 1 ohm. The secondary windings, however, will have between 10,000-15,000 ohms of resistance. When testing a coil, these resistance specifications are what you will be looking for to ensure the coil is functioning properly. Excessive or no resistance in either pair of windings will cause the coil to malfunction and can lead to low spark energy, or none at all. This disparity (as long as it is within a specified range) in resistance levels actually helps the coil to produce higher levels of spark energy and prevent electromagnetic interference (more on that later).

The coil is fired by the disruption of electricity to the primary winding. When energy is flowing through the primary winding, the iron core in the coil acts as an electromagnet, creating a magnetic field around itself. When the voltage to the primary winding is interrupted, it causes the magnetic field to collapse. As the field collapses, it excites electrons and induces current in the secondary windings, causing a high voltage surge that produces the spark energy necessary to jump the gap between the spark plug electrode and ground strap igniting the air/fuel mixture in the cylinder.

Once a coil has discharged its energy, it takes time for it to come back up to its maximum charge level and be ready to fire again, this is referred to as dwell. You may have heard of dwell angle in older, distributor-controlled ignition systems. This is a measurement of how long the points are closed given in degrees of camshaft rotation. In other words, it is the time that the points are closed allowing the coil to recover from discharge. In modern ignition systems, dwell is measure in milliseconds. The computerized systems of today are much better and vastly more accurate at regulating dwell and thus at repeating strong ignition events; leading to better emissions, fuel economy and throttle response.

Ignition Wires

Again, while ignition wires seem more than simple, there are actually many complicated factors to take into account when designing them. Since modern ignition systems don’t use wires that are nearly as long as their progenitors, there is less resistance for the spark energy to fight through to reach the spark plug — which again, leads to high spark energy transference and thus better fuel economy, more precise ignition events and more power.

However, with less resistance comes higher electromagnetic interference (EMI); which is sometime referred to as radio-frequency interference (RFI) when speaking in terms of radio frequency. The less restricted a circuit is, the better it is at creating a magnetic field (which, as we previously mentioned, is one of the main reasons the primary winding in a coil has low resistance).

These two variables create a juxtaposition with one another. You want as much spark energy as possible reaching the spark plug — which would mean less resistance. But the lower you allow the resistance to go, the more it interferes with key electrical components such as the fuel injectors, computerized systems and even the radio. Most manufacturers have settled for a happy medium which keeps EMI to a minimum while transferring as much spark energy as possible.

While compromise is great for selling to the masses and keeping the majority of people happy, it frequently doesn’t help you go faster. Granatelli refused to compromise on performance or drivability with their Malevolent coil pack sets for LT-series engines and found ingenious ways to get the best of both worlds, which is why we turned to them for the punch we needed to put C700 over the top.

Granatelli’s Malevolent Ignition Coils

“On a factory LS or LT engine, the factory coils are rated at about 42,000 volts,” said Joe Granatelli, owner of Granatelli Motor Sports. “Our coils are 85,000 volts, meaning they are double the voltage of the stock coil— what’s special about that is, no one else can do it.”

Granatelli attributes the fact that his company’s coils can produce more spark energy than any other competitor to the fact that the coils are produced domestically and investment in new techniques that allow a more compact design. This ensures that quality control on the units can be monitored directly, and allows the company to produce a coil with more windings packed into their compact shells.

We have customers that are running 2,500+ horsepower pro-mods that aren’t running a magneto. They are still running our coils, and having no problems with them.- Joe Granatelli, Granatelli Motor Sports

He continued, “A lot of other manufacturers aren’t willing to put in the money or effort to figure out how to develop processes to get tighter winding to fit in the compact casings. We wanted to produce the highest voltage coil possible, and we didn’t take any shortcuts to get there.”

But that leads to another question. Do you really need that much more voltage?

“In a forced-induction application, like a supercharged C7, the boost increases the cylinder pressure and starts to cause spark blow out,” Granatelli said. “With our coils, spark blow out is all but eliminated — the stronger the spark the less likely people are to have problems with it.”

He continued, “We have customers that are running 2,500+ horsepower pro-mods that aren’t running a magneto. They are still running our coils, and having no problems with them.”

Not only does the additional power keep things cooking, especially under boosted conditions, it helps to ensure that the coils are producing adequate spark energy at higher rpms, where stock coils have a tendency to become saturated, according to Granatelli.

Higher rpm situations can see a coil’s energy production levels reduced to as low as 22,000 volts in the upper levels of the power band. Not so with the Granatelli coils.

“Our coil on first hit, and in most conditions, is 85,000 volts,” Grantelli explained. “In testing, under high load and high rpm conditions, we’ve never seen them go under 78,000.”

This ensures that C700 will be igniting the entire air-fuel mixture throughout the rev range, regardless of boost pressure, leading to, you guessed it, more power.

Once all that power is produced and the energy is discharged from the coil it heads to our set of Granatelli spark plug wires.

We selected a black set with the additional high temp sleeves to ensure that our freshly installed set of headers wouldn’t cook them to a crisp. They are also available in blue, red or yellow — no judgements here. You can get them with or without the protective selves that we selected. However, we would highly recommend them, since they will be seeing a lot of heat from the headers.

Granatelli’s spark plug wires feature an 8 mm jacket with fiberglass reinforced braid resistant to temperatures of up to 500 degrees fahrenheit. They are constructed with a solid stainless steel core that produces exactly 0 ohms of resistance, meaning every ounce of spark energy makes it from the coil to the spark plug.

“Our wires basically have no resistance,” Granatelli said. “If you ohmed the wire, you would maybe see .0001 ohm — since its impossible for a wire to have absolutely no resistance — but these are as close to no resistance as you will ever see.”

However, as we previously discussed, if there is no resistance, that means there is an increased possibility for electromagnetic interference (EMI and RFI). So how does Granatelli make sure that they don’t interfere with your cars electronics? Through a process they have patented that ensures none of the electromagnetic energy is making its way outside of the spark plug wire.

“We are the only ones that can get you a 0-ohm wire without EMI or RFI,” Granatelli explained. “That’s where our patent comes in; we have a ring that goes on the outside of the wires, that we call the magic donut, that suppresses all electromagnetic interference.”

We are the only ones that can get you a 0-ohm wire without EMI or RFI. That’s where our patent comes in; we have a ring that goes on the outside of the wires, that we call the magic donut, that suppresses all electromagnetic interference.– Joe Granatelli

Combined with a coil capable of producing up to 85,000 volts, our spark plug wires ensure that ample spark energy is making its way to C700’s spark plugs. After hearing of the coils’ and wires’ capabilites, we were eager to get them on C700 and see what they could do.

Installation

Before we were ready to bolt on the new coils, we strapped C700 to our Dynojet to see what kind of power we were making with our stock coils. We were pleased to see that the ProCharged LT1 was churning out a very respectable 566.32 horsepower and 570.39 lb-ft of torque — which works out to around 675 at the crank using rough estimates. However, we were hoping to see just a little bit more to push us closer to our goal of 700 crank horsepower. So, without even moving the car off the rollers, we started the install of our Granatelli Malevolent 85,000-volt coils.

Installation of the coils was extremely straight forward; especially on a C7 Corvette, and just might be the quickest way to put some extra ponies on to your LT1 — especially if it is running a power adder like we are.

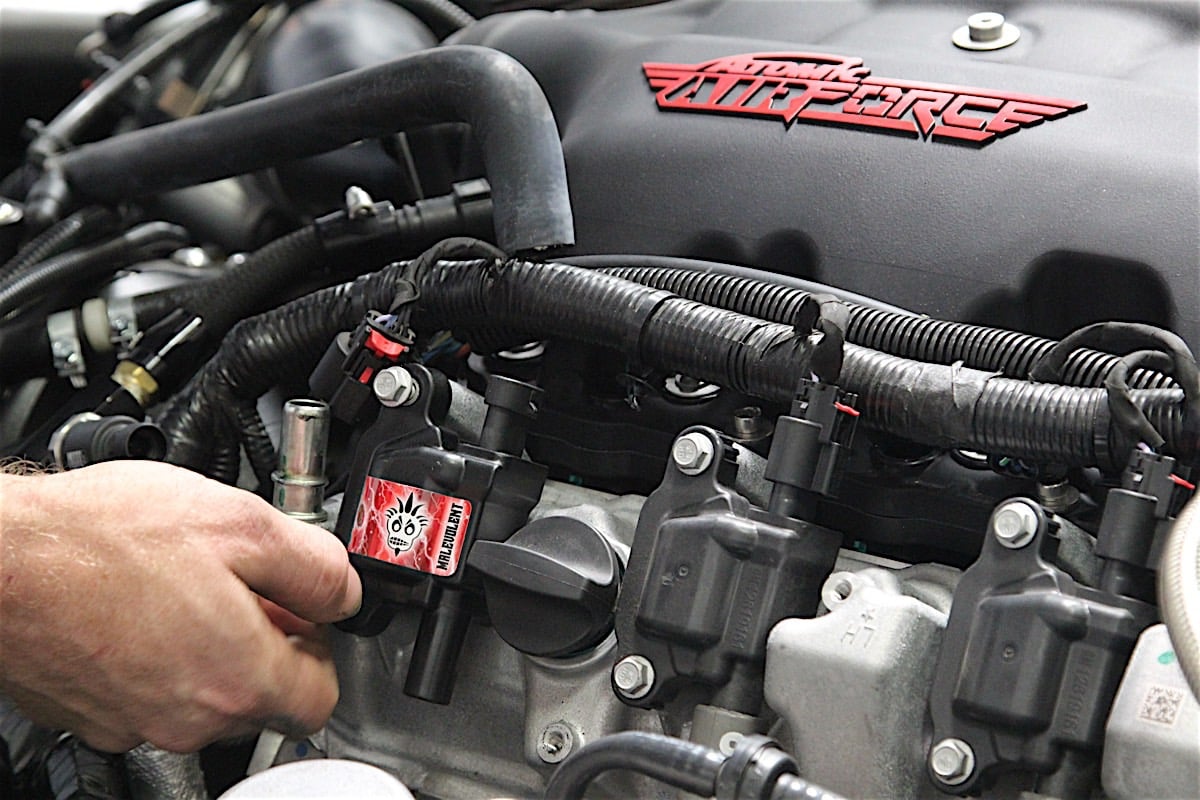

We started by removing the coil covers and unplugging the stock wires from our factory spark plugs. We then unlatched the stock connectors by sliding the red locking tab back and depressing the connectors and gently wiggling them until they broke free.

The spark plug wires we ordered came with the optional spark plug boot protectors. We chose them to ensure that our new wires wouldn't get too hot or touch the headers. As you can see here, the new wires are much beefier than the outgoing stock pieces.

Once all eight of the stock coils were unplugged from their connectors and disconnected from the spark plugs, we began the process of loosening the two 10 mm bolts that hold the factory coils in place. We replaced them all one side at a time, but feel free to replace them in any order that suits your fancy.

After removing and installing the first coil, we decided to move down each bank in one pass.

Once the old coil was out of the way, we reversed the procedure by lining up the Granatelli coils and hand threading the 10 mm bolts, which were then snugged into place. We replaced the connector, slid the locking tab back in place, and then snapped our new spark plug wires into position. Make sure that you feel a positive click on both ends of the spark plug wires to ensure they are seated on the plug and coil correctly.

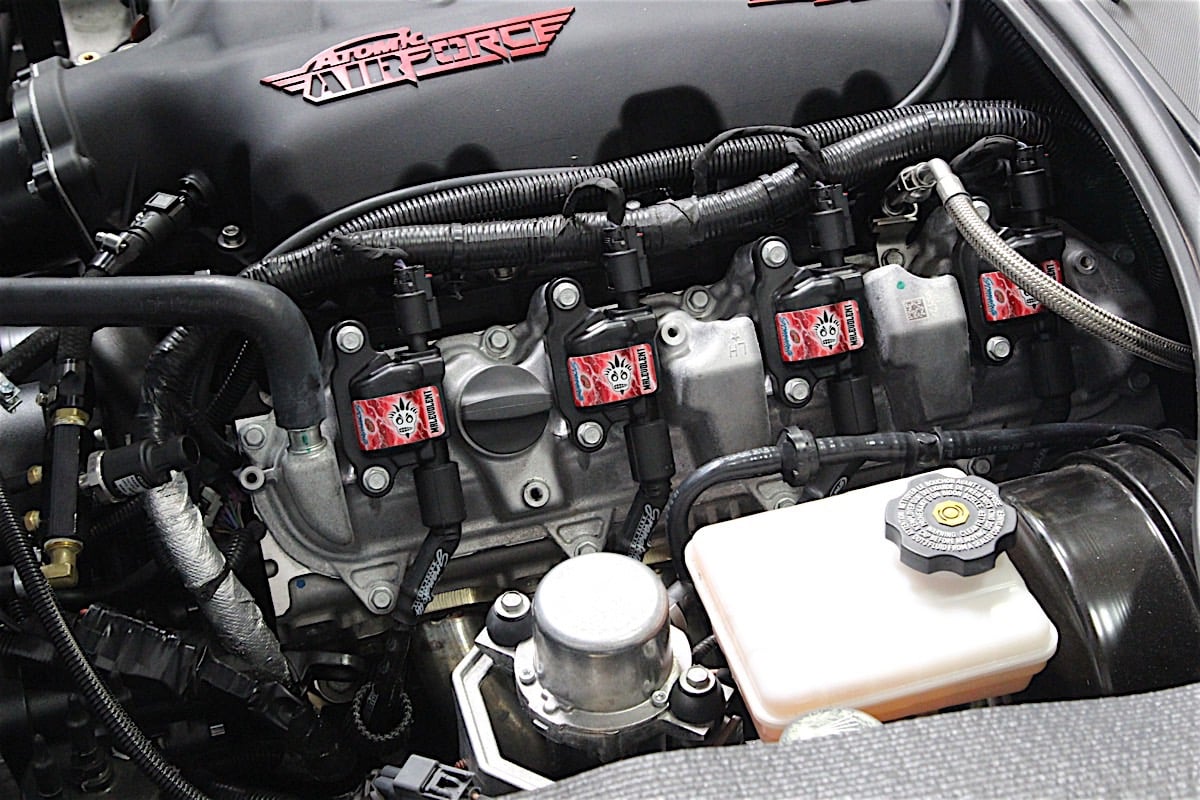

As you can see, there is plenty of room to work with on the driver's side of the engine. Installation was a breeze and only took about five minutes to accomplish.

The passenger side of the car is a little harder to work with but still provides ample clearance. You should be able to complete the job in far less that 45 minutes. Our install took maybe 20. Once we had the coils all back in place, we fired up the motor and gave it a couple of revs to make sure that we were firing on all eight.

As you might be able to tell from the pictures, there is less room to work with on the passenger side. However, there is still plenty of space to work, and you shouldn't have any problems wrapping this side up with maybe and additional five minutes.

After the coils were snugged into place and connected to the wiring harness and spark plugs, we were ready to hit the dyno again.

Once we were satisfied that everything was installed correctly, we were ready to spin the rollers on our in-house Dynojet again to find out just how much power, if any, the coils had brought us. All of our runs were performed in sixth gear, which is a 1.00:1 ratio on the 8L90E transmission used in all 2015+ automatic-equipped C7 Corvettes.

We were stunned to see what the Granatelli coil and wires had brought us in the power department. Power had jumped from the previous 566.32 hp and 570.39 lb-ft of torque to 585.58 hp and 589.12 lb-ft of torque— a gain of 19.26 hp and 18.73 lb-ft! Needless to say, we were thrilled by the power gained by such a simple, easy-to-do swap.

As you can see, our Granatelli Malevolent 85,000-volt coils and 8mm solid stainless steel ignition wires gained us horsepower throughout the rev range, but really showed their stuff in the upper rev range.

As you can see from the above graph, the Granatelli coils start to pull away at 3,200 rpm and never looked back, widening the gap in the upper rpms. This is due to the new coils’ resistance to saturation and lack of resistance in the ignition pathway from the coil to the spark plug. In essence, you are getting a more precise and stronger spark on every fire that is less susceptible to spark blow out created by the ProCharger. This results in a more complete combustion of the air fuel mixture and more precise ignition events, leading to higher cylinder pressures and thus more horsepower.

Using rough estimates (since we don’t know the exact drivetrain losses), that puts project C700 basically on the nose of our 700-crank-horsepower goal. We’ll resist the urge to use a “coming down to the wire” pun and simply say that we were pleasantly surprised to see how much power we gained with the Granatelli coils and wires. Even if you aren’t running a forced induction setup like we are, it seems you would still benefit from an upgrade to a set Granatelli coils and wires. Stay tuned as we hit the track with Project C700 to find out what all of our new found ponies are good for.