Earlier this week, we shared a photo via social media of a highly-modified (relatively speaking)

Fox body Mustang that Nick Plewniak has been racing in small-tire no-prep events this season. The car, which sports an extended wheelbase forward of the firewall, a straight front axle, and no nose, has been rather controversial, and not surprisingly, it drew a bevy of contrasting opinions. One person who saw the chatter was South Carolina racer and fabricator Nate Weimer, who reached out to us privately.

Weimer’s message said, in effect, “hey, I’ve got something I want to show you.” How were we going to turn down an invitation like that?

What Weimer has quietly assembled may be the most unique and modified of no-prep cars to date. It is however, not a new concept, as there are shades of 1960’s-era A/FX’ers and Gassers evident in its design. And, truth be told, both he and Plewniak’s cars are very functional for their purpose, even if they do ruffle some feathers for their looks. The challenge to true no-prep racing of course, is the supreme lack of traction, and so these two (and others) are pushing the envelope as far as they can to maximize weight transfer onto the rear tires, until someone tells them they can’t. Form be damned, this is about winning. And as those modified cars made famous in the ’60s proved, enguiniety translates to victory.

“I really didn’t put two and two together that what I was building was something that had already been done before, until I got done with it,” Weimer says. “I had a ’79 RX-7 that I raced for a couple years, and realized over time I either had to custom fabricate a front suspension with Fox body parts for it, or go with something else. So I bought a Fox body and raced it for a while, and it worked perfectly. Within a few passes it was pretty competitive. But I found that it’s not really hard to make something work like everybody else is doing, but there’s 10 other guys doing exactly what you’re doing.”

“So you get to where you’re showing up to a race and 60-70 percent of the people don’t have a chance at winning, but those that do, have the same chance, because they all have Fox bodies that work really well, all have the same converters, same shocks, it’s all the same,” he explains. “So then it just comes down to who had the better light or got the tune right that day. So I knew I needed to build something where I could make a bad pass and still beat the average Fox body that’s doing everything perfect.”

Weimer didn’t borrow from the past for inspiration, but simply took physics into account: he needed to move the center of gravity back and up. “By doing that, if you create a vehicle that’s 2,000-lbs versus 3,000-lbs. and the center of gravity is higher and further back, it’s going to transfer weight easier, go faster, and it’s not going to care as much about how bad the surface is as a heavier car.”

What Weimer did was purchase a 1994 Chevy S-10 standard cab pickup. He trimmed the bed forward of the rear wheels about 18-20 inches, and slid the cab back on the factory frame. In doing so, he retained the factory wheelbase, along with the required factory framerails, floor, and firewall, but achieved a whole different realm of weight transfer. He was then able to move the engine back an estimated 22-24 inches.

He utilized a Tin Soldier 4-link bracket kit and bars, TRS front and rear coilovers, custom-valved AFCO shocks on the front and Viking shocks on the rear, and TRZ tubular front control arms in the build. Weimer estimates the overall front shock extension travel to be 10-12 inches, and around 8-inches in the rear. All of the roll cage and chassis work was completed in his garage under his Area 51 Innovations fabrication namesake.

Garrett Tew at White Bread Tuning and Fabrication built the turbo hot and cold side — Weimer says Tew has done fab work on the last few cars he’s built and “pretty much taught me how to tune the car to an extent and has helped a lot in realizing you don’t have to spend a million dollars to go reasonably fast.” The wing was built by another local, Felix McLellan.

“I’m starting a shop focusing on street and no-prep cars for the ‘regular guy,’ instead of a shop that does chassis work on $200,000 cars for radials,” he says. “I want to work on regular guys’ cars with regular guy budgets. Right now, no-prep guys only have the option of building stuff themselves or paying a person that really does radial prep stuff mostly to build them something they aren’t familiar with, and it’s usually out of the normal guys’ budget. And I want to change that if possible.”

In addition to most of the fabrication, Weimer also did all of the wiring and plumbing, which includes a Megasquirt Gold ECU. “The basic setup is nothing fancy as far as electronics, other than C02 boost control; there’s no traction control, no fancy shock sensors, or any of that stuff,” he says.

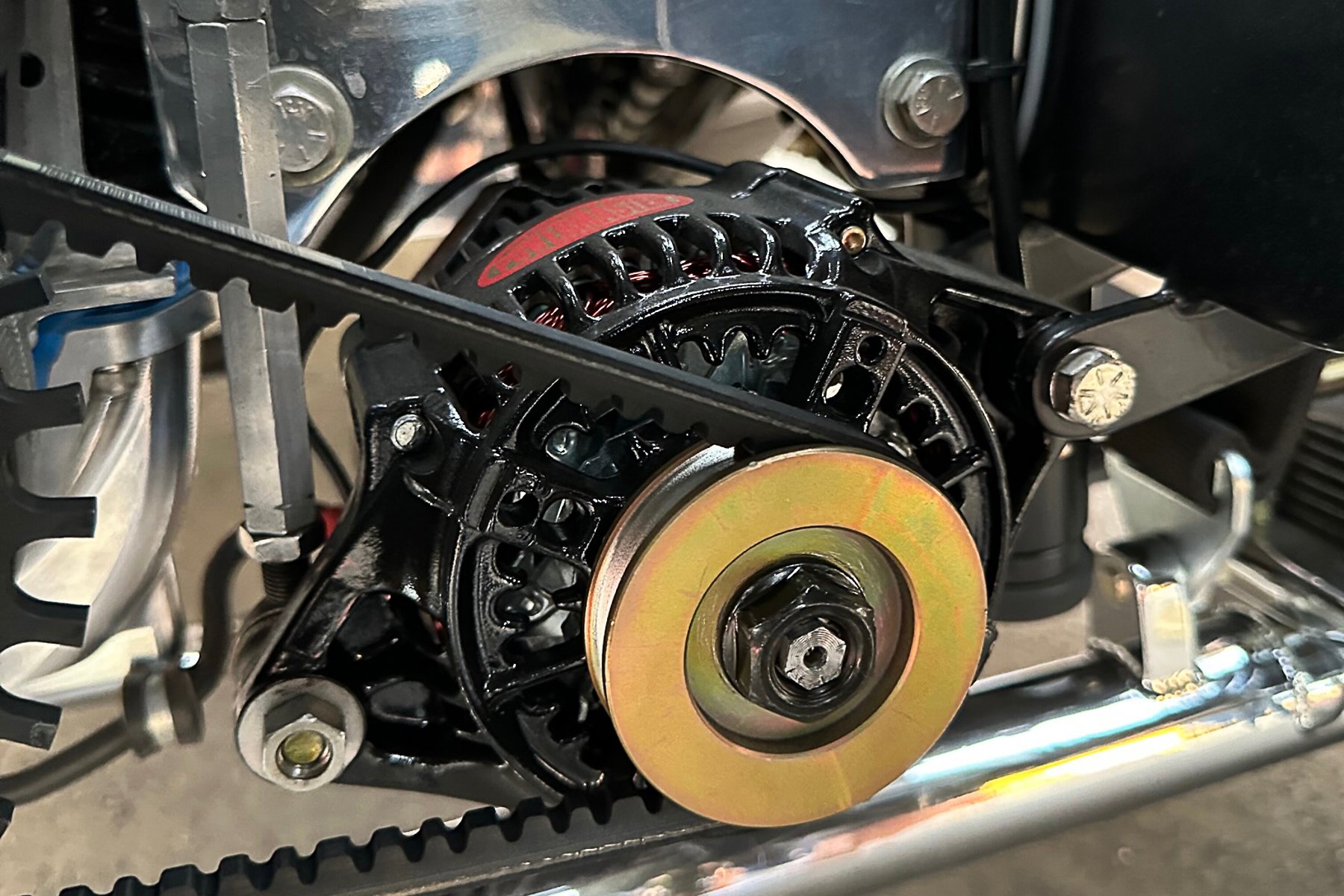

Powering this wild ride is an aluminum Gen IV LC9 block, with stock 799 heads. Weimer procured a forged rotating assembly and had it all built by Richard Coates in North Carolina. The mill will burn M1 fuel, fed through 16 Bosch 210 injectors via a belt-driven pump. Boost is provided by a pair of Comp 76/75 turbos. The power transfers through a Hughes Powerglide and billet bolt-together converter.

“I put the whole idea together and started questioning whether it would work. Over a month or two of working on it and sitting back and thinking about it, I got to researching and found some of the old cars from ’60s and realized that what I was doing, they had already done a long time ago for the same reasons, just with primitive technology,” he says.

In recent days, he tested the “UFO” on the street with a Dragy, and while the numbers are a secret between us and him, he found traction to be satisfactory enough to begin plotting a plan to debut it, where it is sure to draw plenty of attention, both positive and negative.

“I think some people will see it for what it is — the evolution of racing, and that it’s come full circle,” he says of the expected reception. “Some people really don’t want things to change, for whatever reason, whether it’s going to cost them money, they won’t be competitive, or they just don’t like to see change. A measurement of success in drag racing is, when you bud a car, if it doesn’t work, nobody gives a s—t, but when you build a car that works, people are going to come to two conclusions: one, make it illegal, because they don’t want to do that, or two, say it’s a good idea, let’s all start doing that. And I think that’s what is going to happen, they’re going to realize it makes sense and they can go faster than they’ve been going. But in the past, they split it up between cars that were altered and those that weren’t, so I feel like it will go that way again — some guys like me will want to push the limits.”

“A lot of guys build a car with basic setup and then once it’s done they’ll put 500-lbs of ballast in the back, and they’ll get it work, but then they’ve got a 3,500-lb car,” he continues. “I tried to build this from the ground up so I didn’t have to add any ballast at all. I missed the mark slightly I believe, but it’s still substantially less ballast and less overall weight than most competitive no-prep cars on a small tire. So far I’ve made three small ‘test hits’ with 60 to 80 feet of 100-percent TPS and it seems promising.”

Weimer named the truck the “UFO,” in part because it’s sanded down to the bare metal and cleared. “In person it’s really weird, and almost takes a minute or so to even realize what it is, so it kinda’ made sense with it being unidentifiable. And hopefully it flies,” he closes with a laugh.