In case you missed it, our sister publication, EngineLabs, held an engine giveaway in conjunction with the PRI Show last winter in Indianapolis. During the show, Late Model Engines (LME) of Texas built one of its signature LS7-based 427 powerplants filled with all the latest high-performance parts. To add to the fun, Vortech Superchargers offered up one of its LS bracket race kits with a V-30 105A centrifugal supercharger. Vortech also offered the winner the option of selecting a more street-friendly kit using a C5/C6 Corvette FEAD hardware to mount one of its V-7 YSi-B supercharger units.

LME assembled this engine on the floor at the PRI show in December 2021, and mounted a sample Vortech blower to give the PRI crowd a look at the quality of their handiwork. When the name was drawn, Celeste Haskins was the lucky winner. Since she plans to put the LS beast into a real street-legal sleeper, a 1991 Buick Roadmaster Estate Wagon, complete with the faux wood paneling on the sides, she chose the V-7 YSi-B unit.

In this article, we will be discussing Vortech Superchargers V-7 YSi-B with a billet impeller that Celeste chose for her build. The V-30 series is a great blower for drag racing applications, but Celeste wanted something that was more streetable. So, Vortech recommended the V-7 YSi-B to allow her to actually drive her grocery-getter to the grocery store.

Basic Blower 101

Superchargers work by pumping additional air into the engine. Feeding compressed air into the engine allows for more fuel to be burned, resulting in more power. It’s a pretty simple concept, but there are several ways that air can be pumped into an engine, and each method has its benefits and disadvantages.

Superchargers that are used in car engines come in two basic flavors: positive displacement blowers, such as Roots-type and screw-type, and centrifugal superchargers that use an impeller driven by the crankshaft like those Vortech makes.

Centrifugal Superchargers

Centrifugal superchargers use a spinning impeller that draws the air in through the center of the blades and flings it outward to the edge of the impeller through centrifugal force. Since the outer edge is moving much faster than the center, the air is accelerated beyond the speed of sound, which creates a low-pressure area, drawing even more air into the center. The faster the impeller spins, the greater the airflow. The overall process is highly efficient and produces a power increase in the middle and top of the RPM range, allowing for more manageable power levels at lower RPM.

The engineering of the shape and angle of impeller vanes has seen some pretty amazing advances over the years, and today’s centrifugal supercharger impellers can be designed to fit almost any type of internal combustion engine.

Vortech Steps Up

Vortech Superchargers has created a huge line of high-performance centrifugal superchargers that almost anyone can install on a variety of modern powerplants. Founded in 1990 by Jim Middlebrook, Vortech originally created superchargers for Ford high-performance engines, and over time, they have added blowers and accessories for nearly every kind of application, from automotive to marine, and even industrial.

Vortech offered the giveaway winner the large V-30 105A with a cogged-belt-drive, which is aimed at the drag racing market, or a smaller, serpentine-belt-driven unit. Because Celeste is building a street-driver, Vortech recommended the V-7 YSi-B unit, which is similar in many ways to the V-30, but uses a lower step-up ratio, an 8-rib belt-drive, and a smaller inducer that makes it a better choice for street-driven applications.

The V-30 105A has a step-up ratio of 4.21:1, while the V-7 YSi-B has a step-up ratio of 3.45:1. That means that the power comes up much sooner with the V-30, at the cost of higher drive belt load which is great on the drag strip, but it can cause trouble when you want to do a slow cruise to find a parking spot at the grocery store.

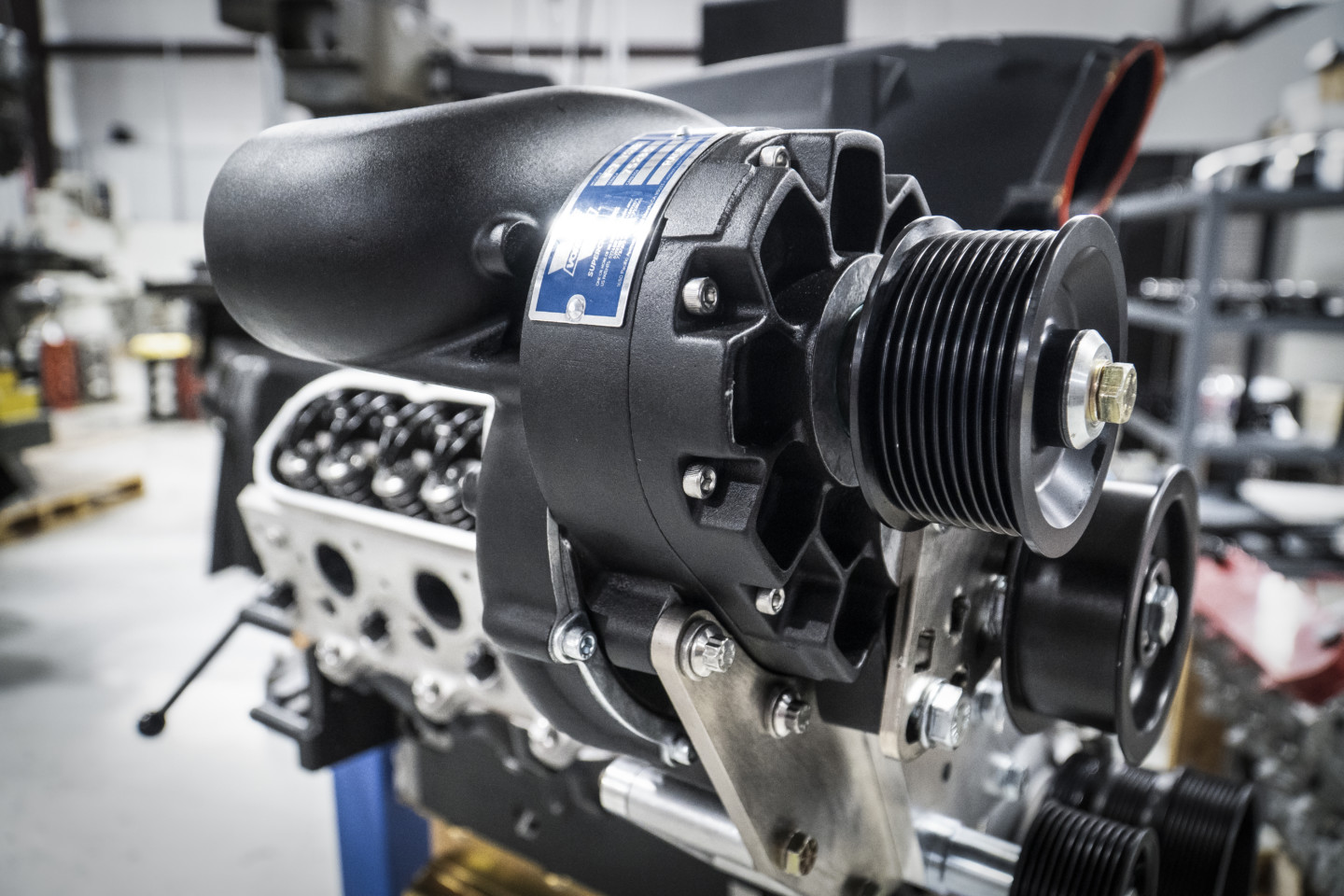

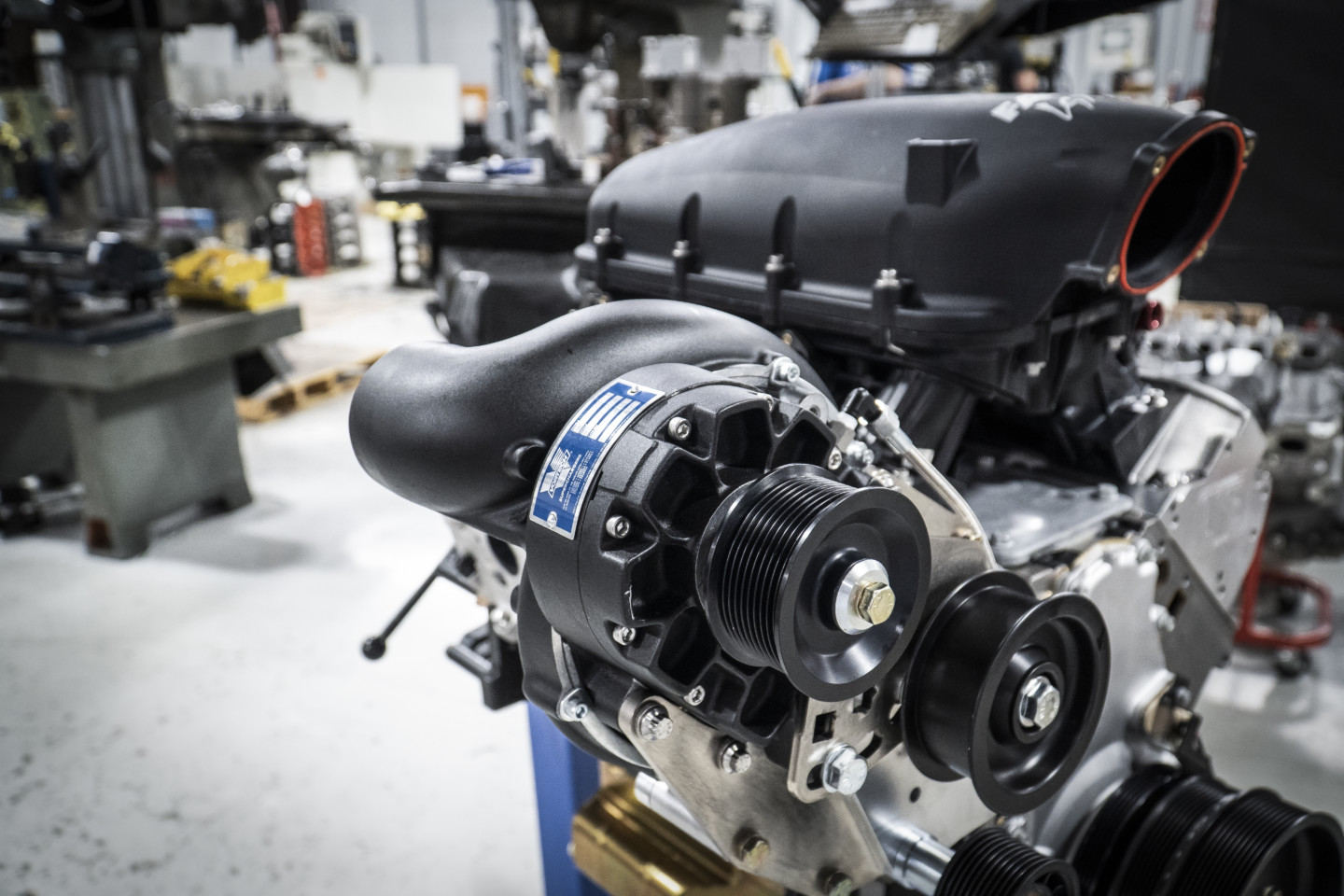

For that reason, Celeste, decided to go with the V-7 YSi-B. Vortech supplied all the hardware needed to mount the blower to the LS7, including the supercharger, plus the mounting hardware from their GM LS-Swap Supercharger Systems for the C5/C6 Corvette FEAD.

Master Plan for the RoadMaster

Celeste already had an LS conversion underway in her Roadmaster, so the LME giveaway engine will fit nicely into her plan. One of the benefits of the V-7 YSi-B supercharger that Celeste chose is the serpentine drive the kit offers. This will allow her to use all of her existing accessories. And the nature of centrifugal superchargers will make the Buick very streetable, with close to 800 horsepower under normal driving conditions, and offering an additional 400 horsepower whenever she decides to spin up the engine past the 5,000 rpm point.

The LME engine will require changes to her original plan for the build. But Celeste says that she is OK with that. “Everything will have to be upgraded to handle that amount of power. I’ve got a lot of research and budgeting to figure out — transmission, rearend, suspension, fuel setup, etc. This isn’t a typical 400-horsepower build and it’s going to be a learning curve for me, that’s for sure. But I’m not only excited for this, I’m so truly blessed. This is a dream come true.”

LME Installs The V-7 YSi-B on to PRI Giveaway Dart 4277976

LME returned home from the PRI show with the assembled engine and then went to work installing the V-7 YSi-B onto Celeste’s engine, AKA “PRI Giveaway Dart 4277976” on the LME in-house paperwork. We’ll just call it “7976” for short.

The optional V-7 YSi-B supercharger that Celeste chose for her build is very similar in many ways to the V-30 105A that Vortech offered for the EngineLabs giveaway. Both feature high-speed ceramic bearings and the ability to use either a cog belt or serpentine-type drive belt.

There are several differences between the V-7 and the V-30 superchargers. One of the biggest is the V-7 uses a drive that’s suited for street use, while the V-30 has a beefed-up transmission designed for racing applications. The higher step-up ratio of the V-30 puts the airflow range way up at nearly 2,900 cfm with the larger 105mm impeller and can produce more than 1,700 horsepower. The V-7’s lower step-up ratio and 94mm impeller keeps the airflow in the range of 1,950 cfm and produces a maximum of 1,400 horsepower. Both blowers can work well on the dragstrip, but the V-7 YSi-B airflow and horsepower numbers should prove to be much more practical in a car that will spend most of its time on the street.

LME recently completed 7976 and sent us some graphs and photos to show their finished work and let us see what kind of power Celeste can expect from the Dart block and LME-ported Brodix BR7 heads topped off with a Vortech supercharger.

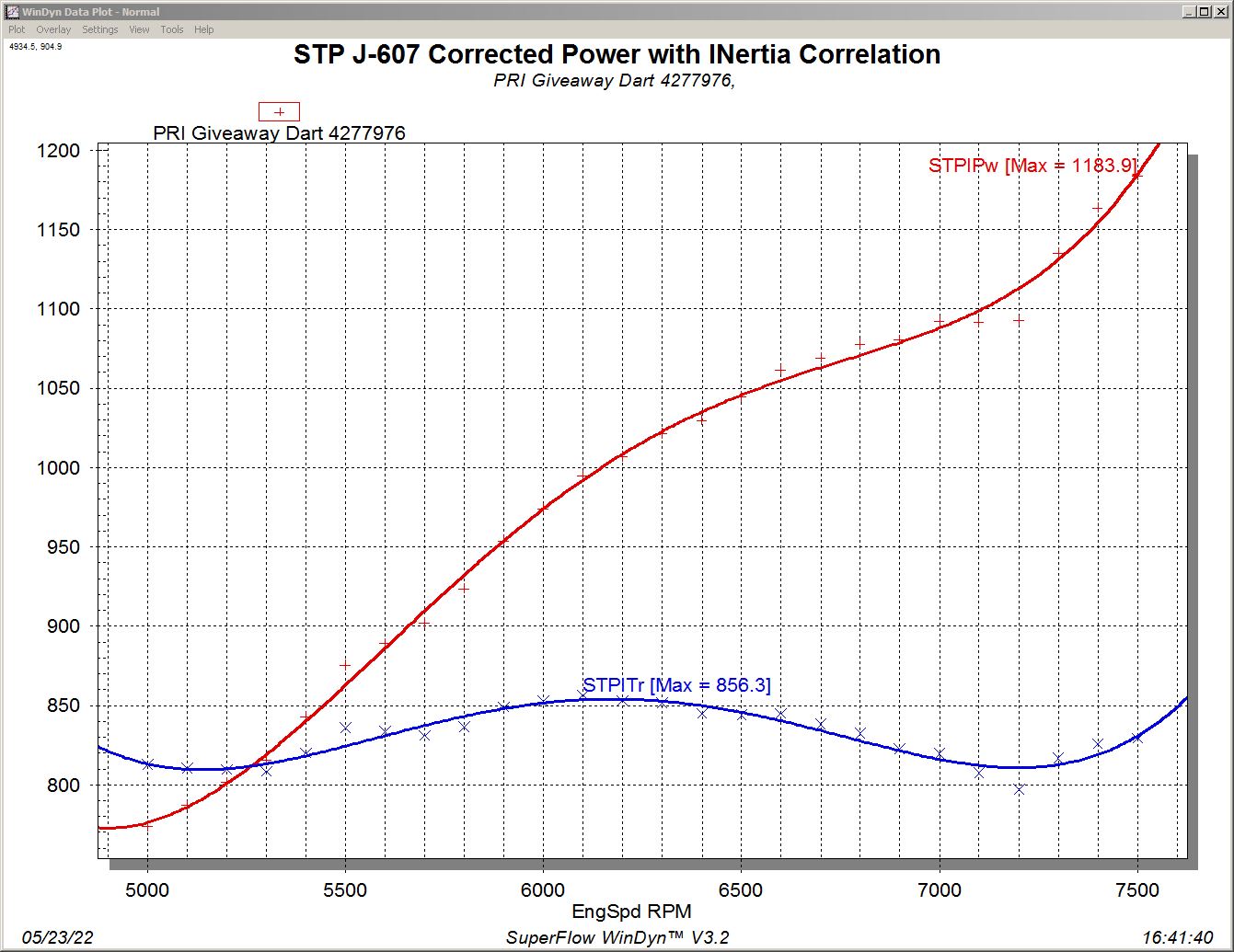

Vortech and LME were targeting 1,200 horsepower on the dyno, and they hit their mark pretty well, will solid peak horsepower numbers of 1,183.9 at 7,500 rpm. That’s not too shabby for a car that will be driven on the street, and maybe occasionally at the drag strip. At 5,000 rpm the horsepower is still pretty close to 800, so getting the big Roadmaster out ahead at a stoplight shouldn’t be any problem. The torque numbers are also impressive, in the range of 800-850 lb-ft throughout the dyno run.

Thanks to Vortech and Late Model Engines for sharing the finished product, Celeste Haskins should have a lot of fun in her Buick Roadmaster with all that horsepower under the hood.