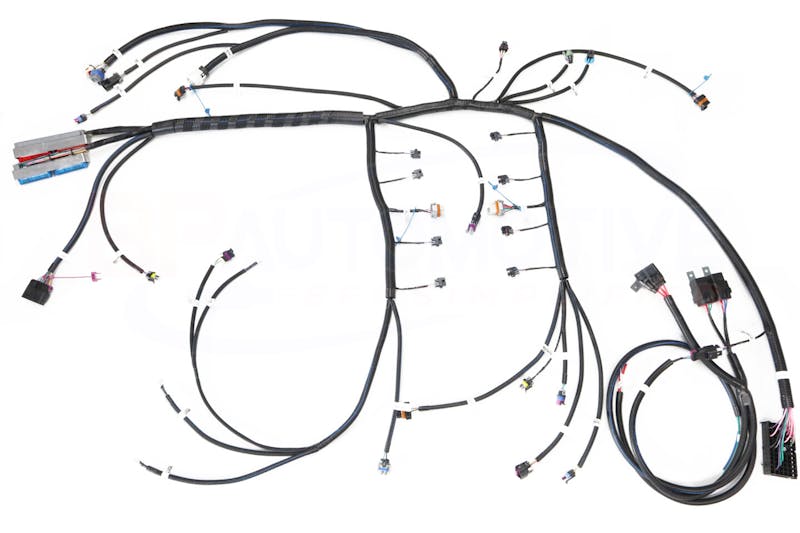

In the early days of the LS swap, chopping, crimping, and taping up a used engine harness was the only viable option. There are a few dozen circuits in an early LS harness just to run the engine, so there was ample opportunity to make a mistake and an eternity to track it down. Thankfully, the aftermarket caught on quickly to help us with all-new LS, and eventually Gen V LT, standalone swap harnesses. It can be tempting to save a buck with cheap overseas harnesses, but that can lead to problems due to poor quality, which is why BP Automotive does in-house LS harness testing on every LS and LT harness that ships to ensure you don’t run into issues.

It’s not always easy to know where today’s aftermarket performance parts are made. In an era where cost-cutting often outweighs quality, some manufacturers will compromise materials or workmanship to save a few dollars. We’ve dealt with an off-brand LS swap harness in the past, and it was immediately clear it came from someone who was lax with quality. The wiring wasn’t automotive-grade, the splices were covered in electrical tape, and the ECU connectors had exposed pins.

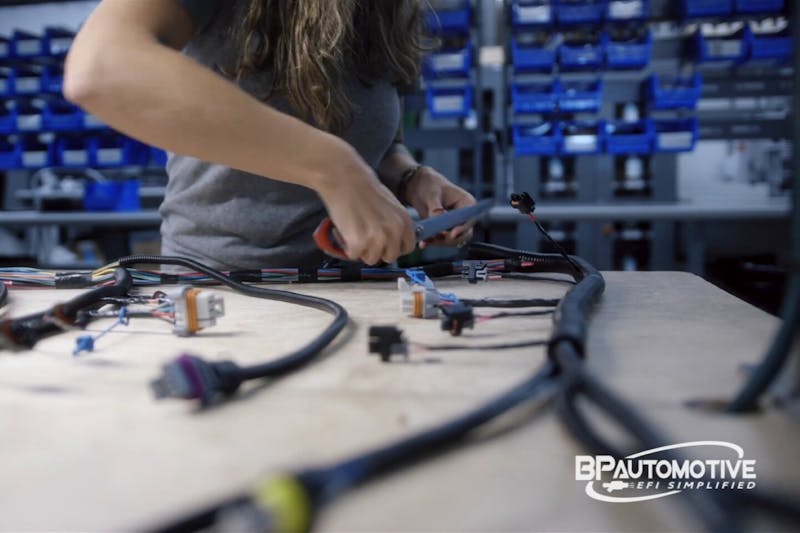

Fortunately, BP Automotive stands on the other side of that spectrum. The company proudly manufactures its harnesses right here in the USA and takes extra steps to ensure every product meets the highest standards. Beyond the advantages of American manufacturing, BP adds another layer of assurance with a dedicated LS harness testing process before any harness leaves its facility.

LS/LT Harness Testing System

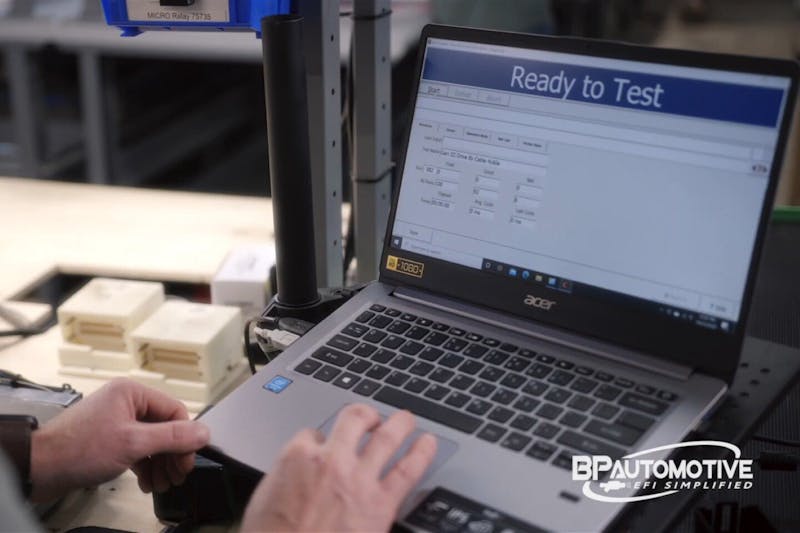

Anyone who’s worked in a hands-on job knows that even the best employees can have an off day. Now, imagine assembling a complex EFI swap harness containing hundreds of individual wires, terminals, and connectors. One misplaced pin could cause hours of troubleshooting, frustration, and downtime. To eliminate that risk, BP Automotive developed a safeguard with its in-house computer harness tester.

This system ensures that every harness is 100 percent verified before shipping. If an issue arises later, BP knows it stems from installation rather than assembly error. The tester can even pinpoint specific wiring faults with precision. The end result? Peace of mind for the customer, knowing their BP Automotive harness is as reliable and accurate as the engine it’s connected to.

We’re very specific in what we do, even down to the tenth or hundredth of a millimeter for crimp height and width. —Bill Hillock, Owner of BP Automotive

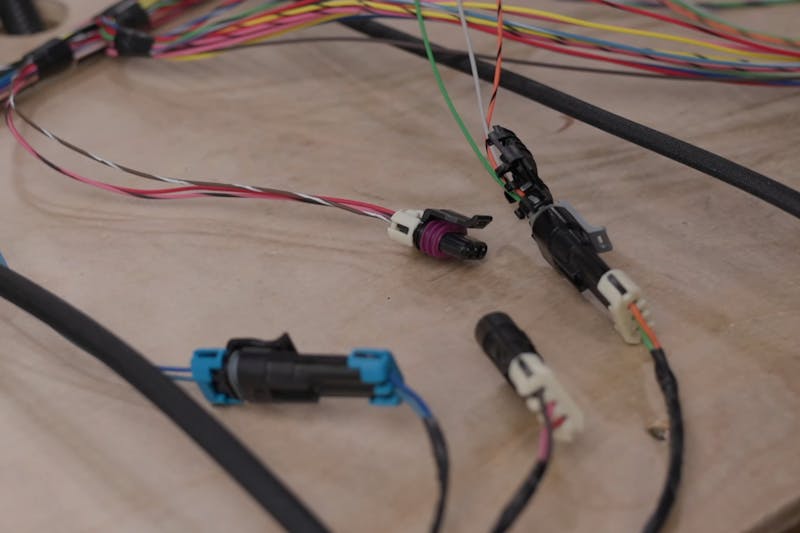

Bill Hillock, owner of BP Automotive, isn’t just the big boss; he’s heavily involved and hands-on with the business. Bill shows us the different ways his LS harness testing computer program can catch quality control problems like a missing or broken wire, a pin in the wrong location, a connection with too high of resistance, and a short circuit between two or more wires with adapters that mimic these problems.

No Connection

Starting with a 24x standalone LS harness, Bill begins the demonstration by connecting the first adapter designed to simulate a missing circuit or a broken wire in the cam sensor signal side of the harness. In this case, the adapter intentionally omits the signal circuit from the connection to show how the test system reacts. Once the adapter is plugged in, Bill powers up the computer harness tester, and the software instantly begins running its diagnostic routine. Within seconds, the system identifies that the cam sensor signal circuit is incomplete, confirming that there’s an open or missing wire in the harness.

What makes this testing process impressive is the level of detail it provides. The computer harness tester doesn’t just detect that a fault exists; it shows exactly where the issue lies within the harness, pinpointing the start and end points of the missing or broken wire. This precision allows BP Automotive to verify the integrity of every connection before a harness ever leaves the shop, ensuring each customer receives a product that’s been fully validated from end to end.

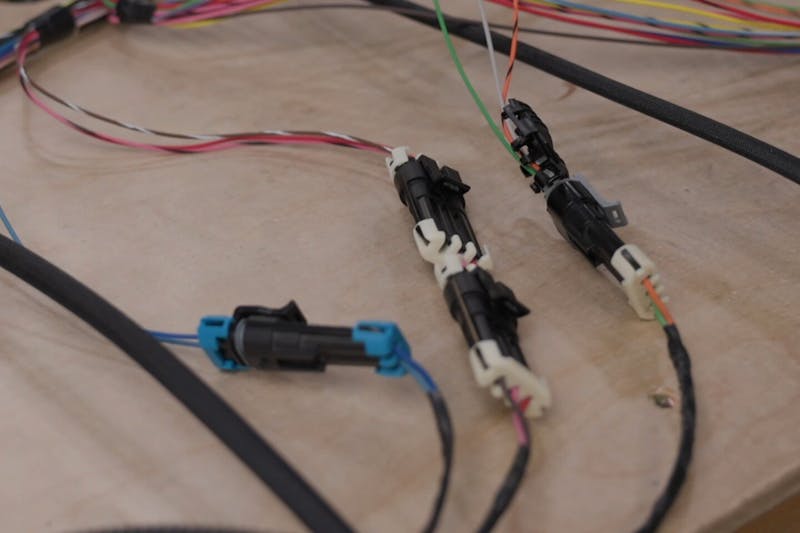

This Pin Is A Little Lost

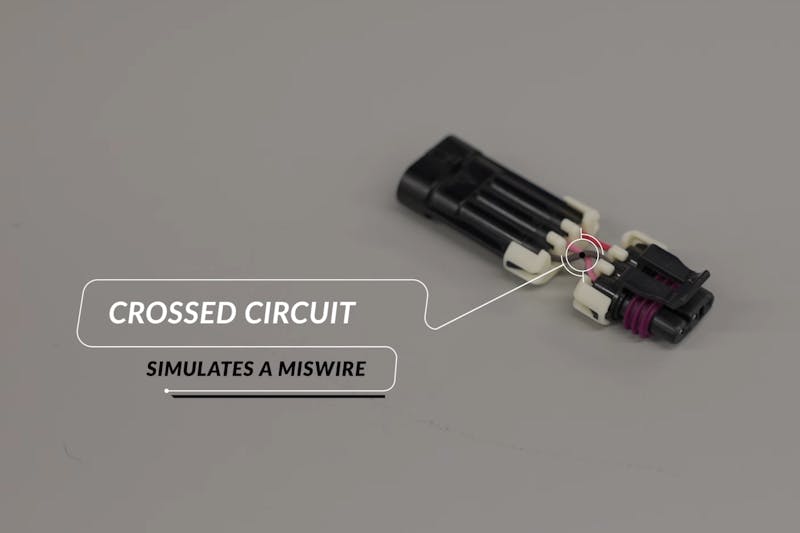

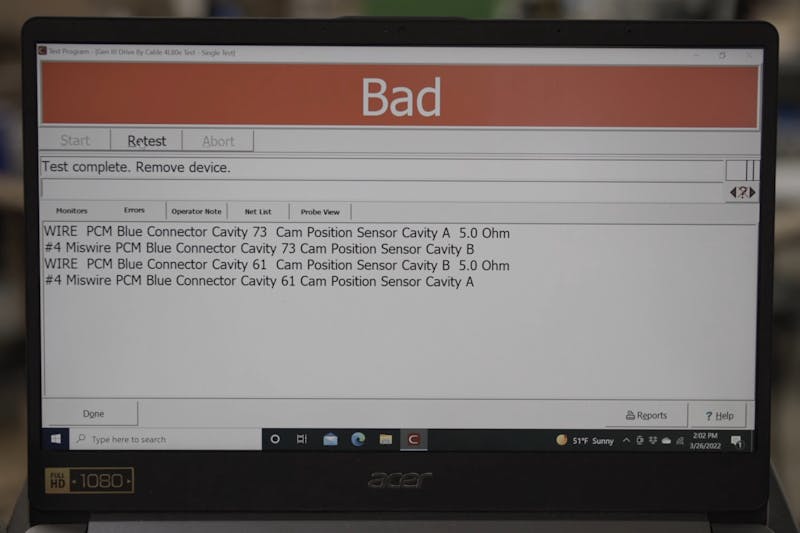

The next adapter that Hillock tests is known as the crossed wire adapter, which is designed to simulate a common assembly-line mistake: mis-pinning a connector. In a complex LS engine harness with hundreds of wires, it’s easy for two terminals to get swapped during production, and this adapter allows BP Automotive to test such errors. Once the adapter is plugged in, Bill initiates the diagnostic sequence, and within moments, the computer harness tester identifies the fault. The software highlights which specific wires have been crossed, instantly flagging the error for review.

In this case, the test reveals that pins A and B are reversed at the cam position sensor connector. What’s impressive is that the system doesn’t just alert the user to a generic fault; it displays the exact pin cavities at both the PCM and the sensor connector where the mistake occurred. This precise feedback means technicians can immediately pinpoint and correct the miswire without hunting through the entire harness.

Too Much Resistance

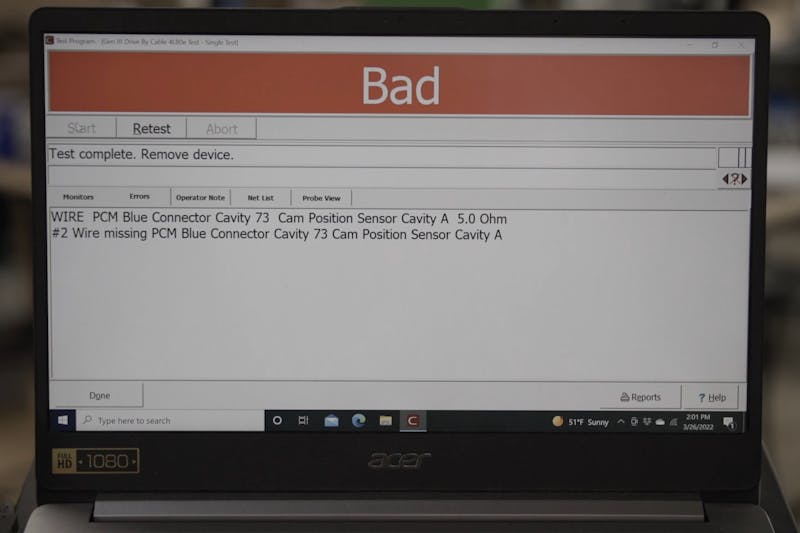

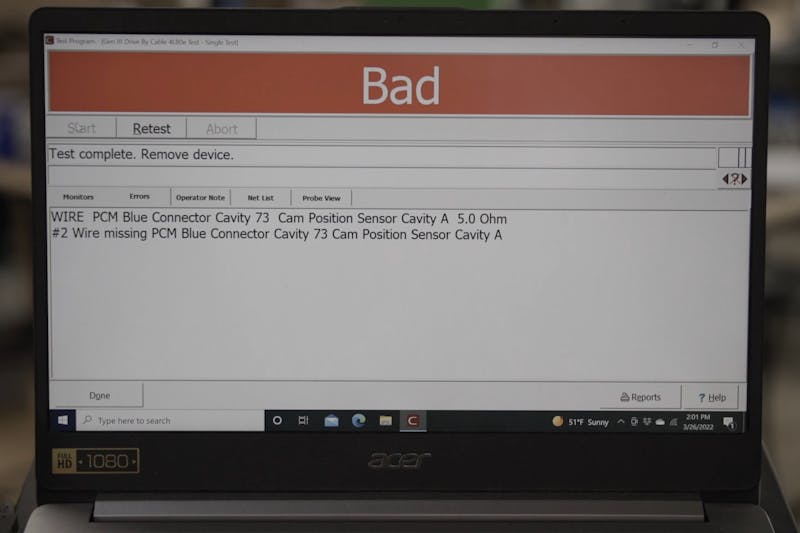

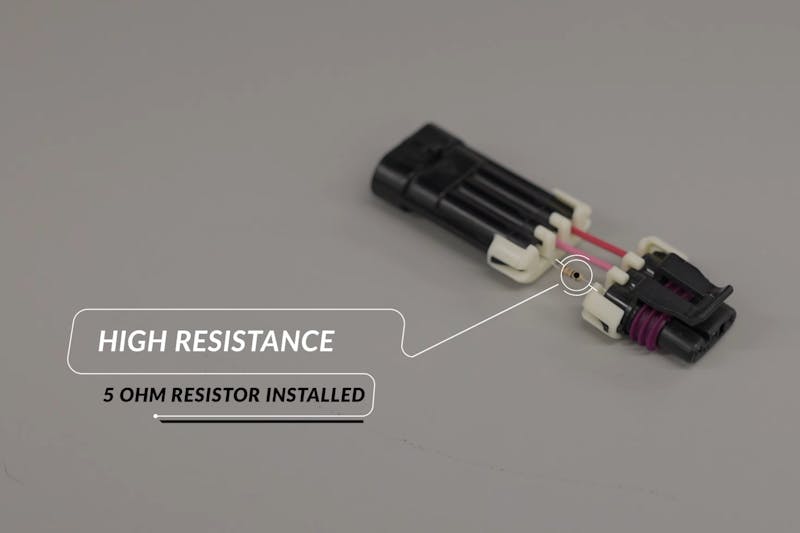

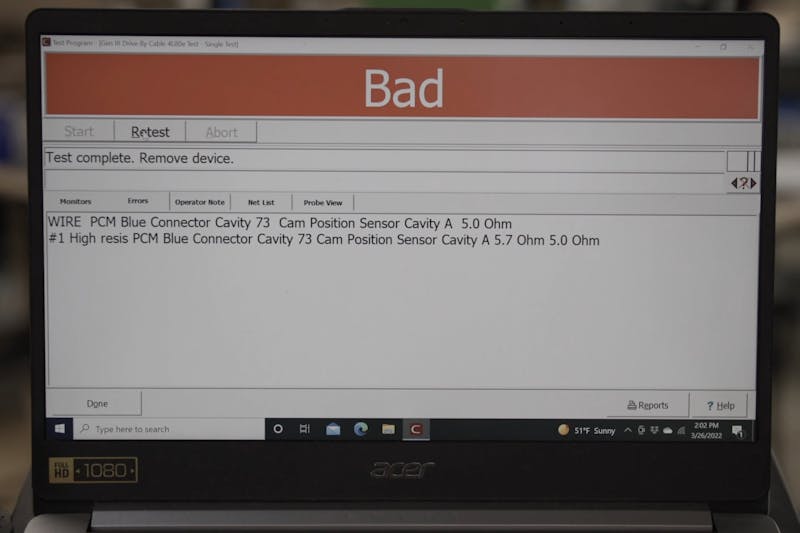

The third adapter Bill Hillock demonstrates in BP Automotive’s LS harness testing process is designed to simulate high resistance in the cam position sensor signal circuit. Unlike a missing or crossed wire, this type of fault is more subtle and can easily go unnoticed during assembly. The company’s testing standard is strict, and any resistance over 5 ohms will trigger a failure in this circuit. To illustrate just how sensitive and accurate the system is, Hillock installs a 5-ohm resistor into the circuit before beginning the test. Once the software runs its check, the results appear instantly on-screen, showing a total resistance of 5.7 ohms in the circuit for pin A at the cam position sensor signal.

That small increase of less than one ohm is enough for the system to flag a potential problem. In a real harness, such a reading would suggest a damaged or compromised wire—possibly a broken strand hidden inside the insulation or a poor crimp at a connector. This kind of precision ensures that even the smallest electrical irregularities are caught before the harness leaves the shop. It’s a level of scrutiny that prevents future troubleshooting headaches and underscores BP Automotive’s commitment to OEM-level reliability and performance in every LS swap harness they produce.

This is why we do it this way. It’s because this is the standard, and we want to meet the standard. The true standard of what it takes to build a harness to GM standards. —Bill Hillock, Owner of BP Automotive

A Short Circuit

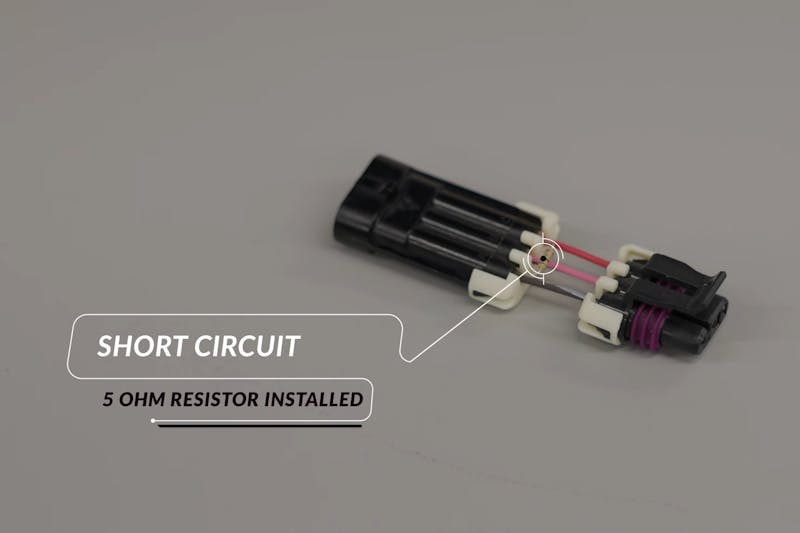

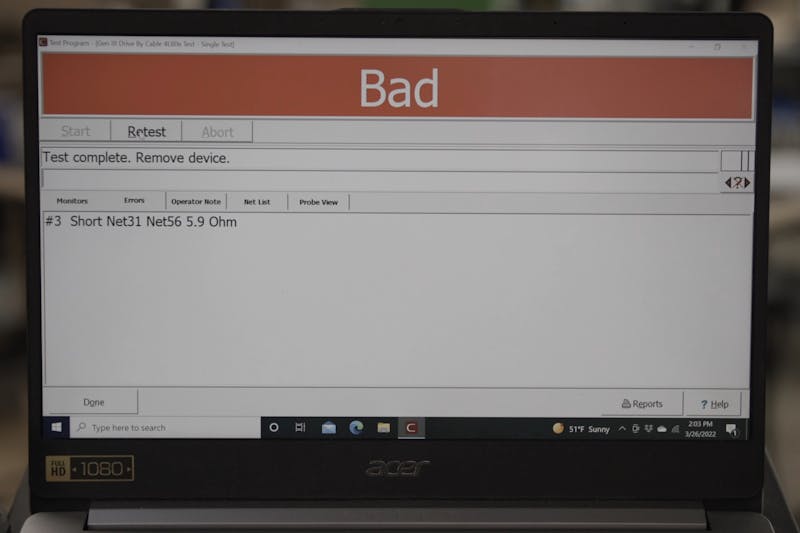

For the final LS harness testing demonstration, Bill connects the fourth and final test adapter, which is designed to simulate a short circuit between pins A and C on the cam position sensor connector. These pins represent the 12-volt reference and sensor signal circuits, two of the most critical paths in the camshaft position sensor circuits that can’t be crossed. When shorted, they create an electrical overlap that could cause erratic sensor readings, ECU faults, or even prevent your LS from running.

Hillock explains that while the BP Automotive computer tester won’t explicitly say “short between A and C,” it still identifies the issue through its network of connections, since the short technically spans four total connection points within the system.

Even though the readout doesn’t pinpoint a single circuit-to-circuit short, it immediately alerts the technician that multiple connections are behaving abnormally. This level of diagnostic feedback allows BP Automotive’s quality control team to isolate, trace, and repair the fault before the harness ever leaves the shop. The process highlights just how comprehensive their in-house testing is at catching not only the obvious open or crossed wires, but also the complex shorts that can cripple an EFI system once installed.

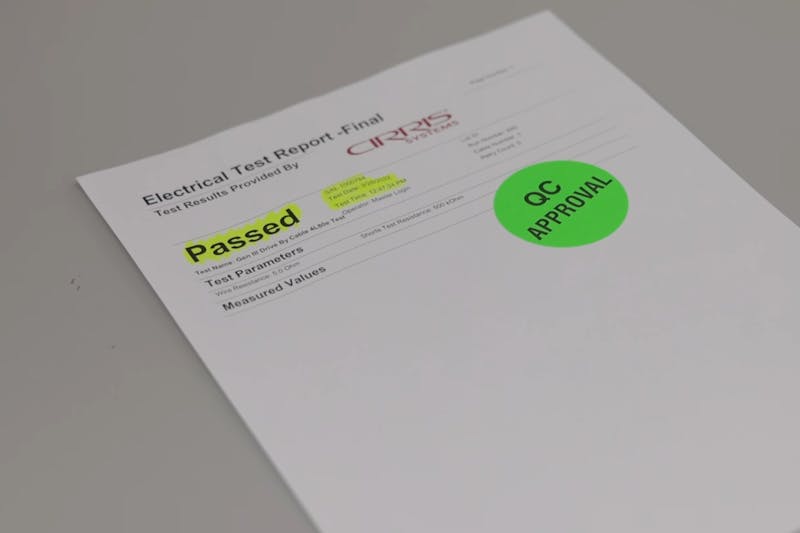

Tested, Tracked, And Trusted

Every BP Automotive harness that completes testing comes with a printed report verifying that it has passed the company’s full diagnostic inspection. This isn’t just a checklist; it’s a record generated directly by the same computer harness tester used during quality control, confirming every circuit’s integrity and signal path. If the harness doesn’t pass every phase of testing, the printout simply doesn’t generate. That means customers can be confident that any harness shipped from BP Automotive has cleared a rigorous electronic audit and is ready to perform flawlessly once installed, so you don’t pull your hair out hunting electrical gremlins.

For standalone LS harnesses and select specialty models, BP takes quality control even further by assigning each one a unique serial number. This number, printed on a sticker near the fuse block, corresponds to the individual test report recorded by the system. It’s more than just a label — it’s a traceable certification of craftsmanship and accountability, ensuring that every harness can be tracked and verified from assembly to installation.

You might also like

Melling LS Valvetrain Kit Focused On Measured Performance

The Melling LS valvetrain kit combines matched valves, springs, and hardware for LS builds selected by specification rather than application.