Overheating issues are a common occurrence in older vehicles and hot rods, and nothing is worse than being stranded on the side of the road waiting on the radiator to cool off enough so you can drive a few more miles before it happens again.

When it came time to replace the cooling system for Project Payback, our 1968 Pontiac GTO, we turned to PWR Advanced Cooling, and we did so for two reasons. One, the company is known for high-end heat exchangers, and second, they specialize in custom applications. We reached out to Herb Engelhart, Sales & Technical Support Manager for C&R Racing/PWR North America, to get the correct components for our GTO with the newly added Chevrolet Performance LT4 Connect and Cruise crate engine.

Fortunately, we have a lot of room to work with for cooling with Project Payback which is good when considering the cooling system we need for our LT4.

If you need a new cooling system for your project, PWR will need basic information like vehicle make, model, year, and so on. However, additional details are necessary on a unique vehicle like our GTO to ensure proper fitment and performance. Engelhart said, “It’s crucial that we know these elements, as well as, engine type, horsepower, and the application. For instance, is the vehicle built as a street cruiser, road racer, or drag?”

If you need a custom-built unit, you will also need to know the dimensions, configuration, and other details. But don’t worry, PWR builds hundreds of custom parts a year, and will be happy to provide assistance with any custom request.

Cooling An LT4 Connect & Cruise

Setting up the cooling system for an LT4 Connect and Cruise, like the one in project Payback, is more tedious than a standard naturally-aspirated LS engine. Since the engine is supercharged, there’s quite a bit more to the equation than just a standard radiator installation.

With the Chevrolet Performance LT4 Connect and Cruise in Project Payback, it was time to figure out the custom cooling system for the supercharged powerplant.

“The engine will need a separate cooler called a heat exchanger, or low temperature radiator (LTR), to cool the water running through the intercooler bricks, which in turn cools the air being forced into the engine by the supercharger”, Engelhart explained. “We build these heat exchangers and have also recently released a line of bar and plate intercooler bricks for various applications, with the LT4 being one of them. All of our heat exchangers and intercooler bricks are upgrades over OEM.”

Getting The Right Goods

To make sure we got what we needed for our project, we worked with Jason Smith, Sales & Technical Support of PWR, Jason is extremely knowledgeable, as he had experience with the LT4 when he worked with drag-racer Larry Dixon on a similar project. After we went back and forth on a couple of emails, it was confirmed that we needed a radiator that measured 34-inches wide by 18-inches tall and 7-inches thick, including the fans. The radiator was fabricated out of aluminum and has two 14-inch Spal high-performance fans installed on the backside. PWR even built mounts on the front side of the radiator that our custom heat exchanger attaches to.

The heat exchanger is 30-inches wide by 17-inches tall and approximately 1.5-inchs thick. It’s also all-aluminum in construction and has mounts on the front side for an A/C condenser — these guys thought of everything. The entire package is only 9.41-inches thick, including the A/C condenser. Both cores in the two coolers were designed specifically for our application.

More Power, More Problems?

If you’re like us, you probably tend to swap parts on a project in the quest for more speed and power. After all, the name of the game is to go faster and be more competitive. Thinking ahead, a question came up: if we were to swap out the factory supercharger at a later date, would we need a larger radiator? Engelhart said, “Given the size of this particular package, you should not need to upgrade this unit in the future. We engineer our packages to reject way more heat than what’s typically required for a given application. And, this unit is a good bit larger than what we’re generally given for space claims.”

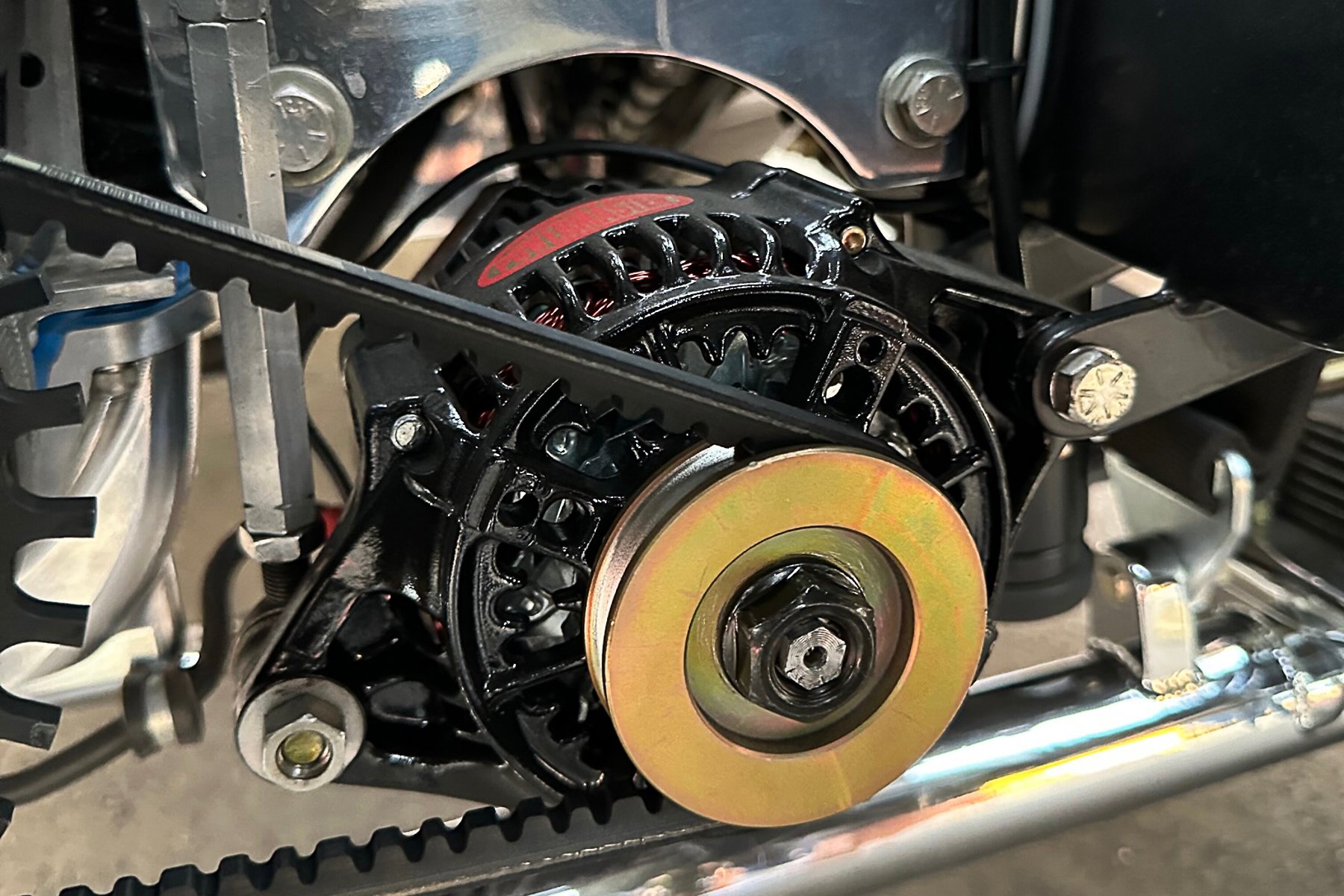

In this image, you can see the low temperature radiator (LTR) for the supercharger mounted to the radiator. Everything about this package is a work of art.

While most of PWR’s aftermarket products are built to cool up to 1000 horsepower, we were assured our’s would handle a good bit more, depending on how the vehicle was being used.

While our radiator is large compared to most on the market, so are the heat exchangers for our application. It should not need to be upgraded, ever,” stated Engelhart. “However, one thing that would elevate this vehicle nicely would be a set of our bar plate intercooler bricks. These would further decrease the intake air temperatures (IATs), which creates more horsepower. Our bricks also recover very quickly after a throttle hit when compared to the stock LT4 units.”

While we decided not to upgrade our bricks at this time, we can always revisit this modification after we get some track time with the GTO to see if it’s a need or not.

Oil Cooler

Oil temperature is often overlooked when it comes to engine vitals because, in the past, it’s never been deemed necessary on a street car. And if a vehicle didn’t have an oil cooler from the factory, the odds of someone adding one are pretty slim. However, with modern technology comes high horsepower, and the more power a vehicle makes, the more heat it generates. Plus, LS and LT engines are known for elevated oil temperatures, which is why we decided to run an oil cooler on our LT4.

While an oil cooler is an excellent idea on any high-performance vehicle, Engelhart tells us that it’s mandatory for a street car making even decent power at the wheels. Engelhart said, “A lot of street car enthusiasts are not used to utilizing an oil cooler. With our racing background, we are. And we find in today’s world, with horsepower levels where they are, an oil cooler has almost become mandatory for any street car in the 600 horsepower range and above. And it only makes sense, in caring for the motor and its longevity to run one verse running with hotter temps and stressing parts,” Engelhart continued. “From our experience with the LS/LT engines, it’s very difficult to keep the water temperature at a reasonable level when the oil temp is in the upper 200-degree range. The two fluids run side by side in the engine, with the oil being hotter, so it’s only natural that the oil temperature will elevate the water temperature to a higher degree, the hotter it is. If you cool the oil down, you will reduce your water temperatures as well.”

To give you an example of how well oil coolers can work, PWR recently developed one for the Camaro ZL1. This test vehicle is a dedicated track car with 800 horsepower, and they were able to reduce the oil temperatures by 45-degrees with just a 10 x 10-inch oil cooler. Engelhart said, “The oil cooler was a huge help controlling the water temperature given the tight space claim for the radiator.”

The Fans

While the radiator, heat exchanger, and oil cooler are all crucial pieces of the cooling equation on our LT4, airflow is, too. Without it, even the most efficient cooling system parts will not get the job done. “Fans are essential as well, as airflow is always the top priority, and this package has some powerful units integrated,” Engelhart explained.”

Each SPAL fan used on our application can move 1,864 CFM of air which is enough to make sure we have plenty of airflow for the track even on the hottest day.

For our package, we used fans manufactured by SPAL, and these are the only fans that PWR has offered for a decade. Each one of the fans on this combination is capable of moving 1,864 CFM of air. “We’re limited in the various fan sizes and models available, as well as the overall depth available. So it comes down to how much space is available on a given cooler and the options for that size fan.” Engelhart continued, “In general, we always spec the highest performing fans available that fit the parameters of the cooler and application. Our engineering department can calculate what is needed at a higher level, but there are many variables. Typically, this additional process is not required for most aftermarket applications.

Coolant Check

Even though we’re not ready to fill up the radiator just yet, there is one more important piece of the puzzle remaining: the coolant. As you probably know, water mixed with antifreeze is the best option for a street car, but don’t use just any water. We know that using tap water is a terrible idea, and we asked Engelhart his thoughts on this topic.

“The best water to use in a cooling system is distilled, as it’s had all the impure minerals removed from it through the distilling process. Tap water is a big no,” Engelhart explained. “It has many minerals and other impurities that lead to build-up and corrosion inside a radiator. I believe the water used in a 50/50 antifreeze premix to be good, but hard to be sure. The safest bet is to mix your own distilled water with full-strength antifreeze.”

Another bad idea along with using tap water is mixing water additives. Sometimes, the enthusiast will run an additive like water wetter or purple ice because they are not allowed to run antifreeze at the track. These additives are designed with lubricating properties for the water pump, since antifreeze is not used. Mixing any of these additives with antifreeze has serious repercussions.

Engelhart said, “Sooner or later, you will get two chemicals that don’t like one another. It will cause a corrosive chemical reaction that will eat the radiator from the inside out. We have seen several cases of this with customers who developed leaks and sent their radiators back to us.”

If you need to change the fluid in your cooling system, be sure to flush out the system entirely before refilling the radiator or heat exchanger. This simple step could save you a lot of headaches and money.

Breaking In A Cooling System

While we’d like to think we know everything about the automobile and its systems, there’s always something to learn. With that said, we were surprised to hear that you might need to break in your cooling system on a vehicle. While speaking with Engelhart he gave us some more valuable information on why it’s essential to break in a cooling system with a new aluminum radiator.

“One thing that’s important for everyone to know is that all-new aluminum coolers using a water-based coolant should be passivated upon filling them with fluid — this is where the virgin aluminum is conditioned through an initial heat cycle. The process more or less puts a protective coating over the aluminum on the inside of the cooler, explained Engelharthe. “A big no-no would be installing and filling a new cooler without being able to start the engine and warm the fluid to a minimum of 180-degrees. Without this process, virgin aluminum has no protection against the chemicals and other impurities typically found in all the various coolants.”

This is an excellent tip to remember before adding coolant in your next project. Failing to do so and not properly heating the coolant will cause problems down the road.

More To Come

As you can imagine, installing an LT4 in an old GTO takes some time and a few modifications. The same is true for the cooling system for the car. Since the vehicle was never equipped with an oil cooler or a heat exchanger, it’s up to us to get everything mounted and all of the new hoses routed in the engine bay. And while this process might sound intimidating for some, it’s not bad. It takes some planning, and we will show you the process in a later article. So, stay tuned!