When it comes to the LS platform, adding a supercharger is one of the most effective ways to unlock huge power gains, whether you’re working with a junkyard 5.3-liter or a fully built 416 LS3-based stroker. But as many experienced builders know, belt slip can ruin an otherwise perfect setup. The moment that blower pulley starts slipping under load, you lose boost and horsepower. For enthusiasts who expect both performance and reliability, the LSX Concepts Flex Drive delivers a purpose-built solution to fix this issue at its core.

The Flex Drive is designed specifically for LS engines using a Corvette-offset accessory drive. Its precision-engineered dual-belt layout separates the supercharger’s load from the rest of the accessory drive, dramatically reducing wear and preventing slippage during high-rpm and high-boost operation. This design not only enhances boost consistency but also extends the life of vital components such as the alternator, water pump, and power steering pump.

Split-Belt Engineering For Maximum Efficiency

The secret behind LSX Concepts’ success lies in the Flex Drive’s dual-belt system. Instead of forcing one belt to power both the blower and all the engine accessories, LSX Concepts gives the supercharger its own dedicated belt. The rest of the accessories run on a separate 6-rib Corvette-style belt drive. By isolating the blower, torque spikes and belt drag are no longer transferred to other components, which means smoother operation and greater reliability under heavy loads.

Each LSX Concepts Flex Drive kit is designed to handle increasing levels of power with precision. The 8-rib version is ideal for builds producing up to around 800 horsepower, the 10-rib setup is designed for those pushing closer to 1,000 horsepower, and the 12-rib configuration is built to support extreme applications exceeding 1,400 horsepower. With each step up, LSX Concepts ensures that the belts maintain optimal grip and alignment, even when the boost is turned all the way up.

Precision Tensioning And Adjustability

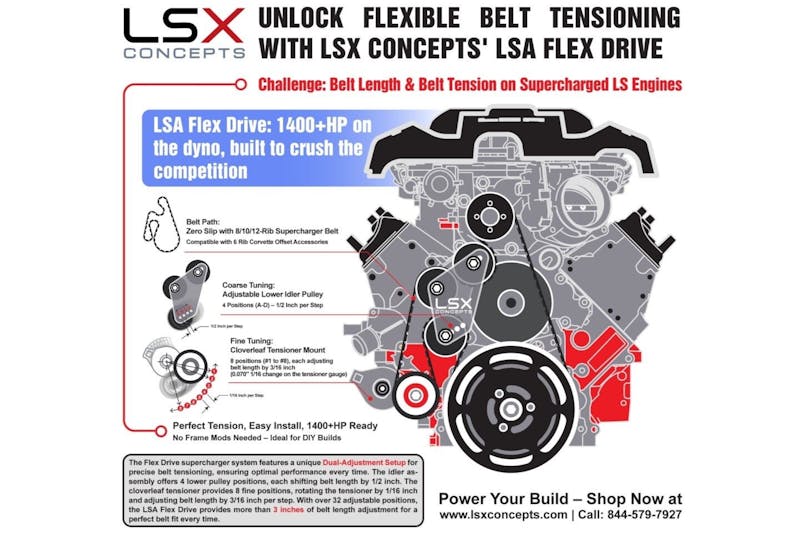

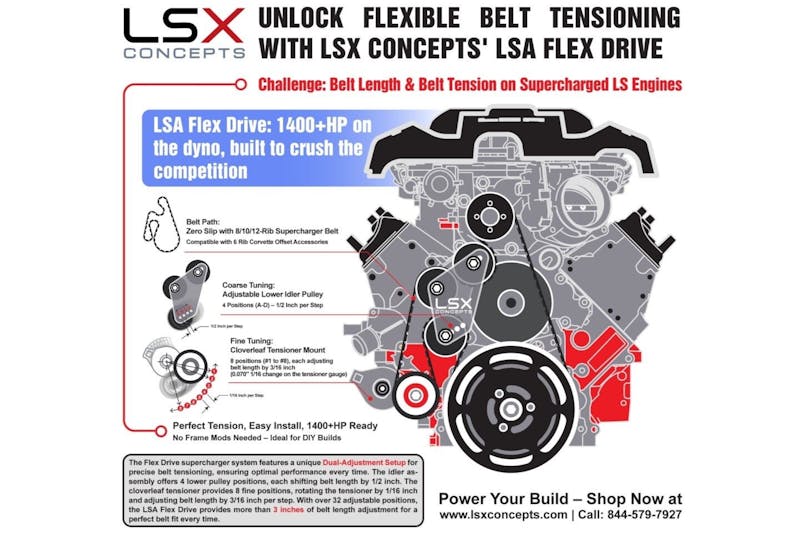

The Flex Drive also features an innovative tensioning system that makes it easy to fine-tune belt tension without guesswork. LSX Concepts employs a cloverleaf-style indexable mount that allows eight incremental adjustments, each spaced just 0.075 inches apart. This precision setup lets builders perfectly dial in tension to suit their pulley combination, ensuring that belts maintain ideal tension across the RPM range.

In addition, an adjustable lower idler pulley provides even more flexibility, accommodating belt length variations of up to two full inches. This design not only helps with fitment during installation but also ensures consistent performance as the belt naturally stretches over time. For builders who like to experiment with pulley sizes or boost levels, the LSX Concepts Flex Drive’s adaptability is a major advantage.

Corvette Offset Compatibility

Another standout feature of the Flex Drive is its compatibility with LSA-offset superchargers. This includes both factory units off the LSA-powered ZL1 Camaro and CTS V, and aftermarket units such as the Harrop TVS 2650, KONG 2650, Magnuson Gen-2 2650, Boost District Gen-2 2650, and Whipple GM LSX Inverted Gen-6 in the LSA offset configuration. Because the Flex Drive matches the Corvette accessory geometry, it fits neatly into many common LS swap applications without requiring major custom fabrication or belt rerouting.

When swapping pulley sizes, the cloverleaf tensioner housing allows you to position the belt tensioner in the sweet spot for maximum belt grip without having to change to a different length belt. -Greg Reimche, CEO LSX Concepts

Installing or servicing the system is straightforward. The front cover of the Flex Drive can be easily removed to install or replace belts, and the design supports lower pulleys up to a monumental 10 inches in diameter. For those running larger crank pulleys to generate higher boost, that capability provides even more flexibility.

Complete Kits Or Custom Configurations

LSX Concepts offers the Flex Drive in several configurations to meet different project needs. Builders can opt for a complete bundle that includes all accessory brackets, alternator, A/C compressor, and power steering components, or they can choose a stripped-down version that provides just the essentials for a custom setup. This modular approach lets professional fabricators and home builders alike tailor the system to fit their specific project, whether it’s a daily-driven street car, a show-quality build, or a full-on track machine.

Each part of the system is designed to work together with OEM-level precision. Proper alignment and balanced tension ensure that even at extreme boost levels, accessories stay stable and efficient. LSX Concepts engineered this system to withstand high horsepower without introducing new headaches during installation or maintenance.

The Weak Link: Why The Stock 6-Rib Setup Fails

Many LS builders start with a simple supercharger swap using a stock truck 6-rib accessory drive. Either they are working on a ‘99 or newer LS-powered truck or a junkyard-pullout LS from a truck application. While this configuration may work initially, once the boost level climbs past 10 psi, the limitations become painfully clear. The narrow 6-rib belt simply can’t handle the increased load, and slippage becomes inevitable.

When the belt slips, boost drops, and power output becomes inconsistent. Builders often attempt to fix this with more aggressive tensioners or different pulley textures, but these band-aid solutions lead to premature belt wear and added stress on the accessories. While 8-rib conversions for the LS truck accessory drive are an option, they can be pricey. LSX Concepts eliminates that problem by designing a system that divides the work properly, letting one belt drive the blower while the other handles the accessories independently.

Proven Performance In Real-World Builds

The most convincing proof of the Flex Drive’s effectiveness comes from real-world builders who have put it to the test. Users across the LS community consistently report stable boost levels, no belt slip, and long-term durability under harsh driving conditions. One user noted, “Zero belt slip, dedicated blower belt got rid of surging I had with a single belt setup.” Another praised the kit’s packaging and reliability: “3 years running on the same belts at 800 whp… still holding the same boost.”

These results aren’t luck, they’re the outcome of smart design. The Flex Drive features a double-shear idler bracket that adds strength where it’s needed most, supports large lower pulleys, and uses robust, factory-style tensioners. The result is a system that performs flawlessly whether it’s idling in traffic or pulling to redline on a track.

Why It Matters For Supercharged LS Builds

Supercharged LS engines place enormous strain on the accessory drive system. The crank pulley must power every component from the alternator to the water pump while simultaneously turning a supercharger that can consume up to 100 horsepower or more just to operate at max output. That torque load translates into tension and heat that the stock belt system simply wasn’t designed to manage.

By isolating the supercharger on its own drive belt, LSX Concepts drastically reduces stress on the accessories. That means fewer broken tensioners, less belt debris, and no more loss of boost pressure at the top end. The dual-belt system provides consistent power transfer, stable accessory performance, and predictable results every time you hit the throttle.

Built For The Real World

The Flex Drive isn’t just an engineered solution; it’s a system built for the realities of LS swapping. Whether you’re building a high-boost street car, a pro-touring restomod, or a dedicated drag machine, it’s designed to fit and function like a factory component. Its CNC-machined parts, double-anodized finishes, and high-strength mounting hardware give it the durability needed for long-term use, even in punishing environments.

The Flex Drive also looks the part. Its compact layout and clean design help it integrate seamlessly into modern engine bays, giving builders both form and function. It’s an elegant piece of hardware that quietly does its job, ensuring the rest of the build performs as intended.

Don’t Get Caught Slippin’

In the performance world, belt slip is one of the most frustrating issues for supercharged LS builders. It robs power, creates inconsistencies, and shortens component life. LSX Concepts Flex Drive solves all of these issues through intelligent engineering and proven durability. The Flex Drive is more than just a clever design—it’s the missing link between raw power and mechanical reliability.

You might also like

Melling LS Valvetrain Kit Focused On Measured Performance

The Melling LS valvetrain kit combines matched valves, springs, and hardware for LS builds selected by specification rather than application.