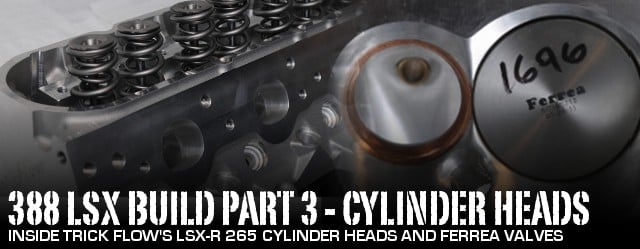

To recap the on-going engine buildup for our Project BlownZ being built for the NMCA/NMRA West 275 Drag Radial Class, the first two parts covered the short block assembly in detail (block prep and short block assembly) on this 388ci, ProCharger F1-blown LS motor. This time around, we’ll go into detail on the Trick Flow Specialties/Total Engine Airflow cylinder heads, what they’re all about, why they were chosen for this application, and what kind of work was done to them.

To recap the on-going engine buildup for our Project BlownZ being built for the NMCA/NMRA West 275 Drag Radial Class, the first two parts covered the short block assembly in detail (block prep and short block assembly) on this 388ci, ProCharger F1-blown LS motor. This time around, we’ll go into detail on the Trick Flow Specialties/Total Engine Airflow cylinder heads, what they’re all about, why they were chosen for this application, and what kind of work was done to them.

The cylinder heads are one of the most crucial parts of the engine when it comes to making power—peak power, what the power curve looks like, and how much torque it makes and where. The Limited Street rules we originally built this engine for limit cylinder heads for a boosted GM LS engine to be within one degree of the stock 15-degree valve angle without a weight penalty. We are also limited to using no bigger than an F-1R ProCharger supercharger at our weight break.

We put a lot of thought into the cylinder head choice for the ProCharged 388ci LSX for Project BlownZ, and in the end we went with a set of Trick Flow's LSX-R 265 heads and let the guys at Total Engine Airflow work their magic on them.

Trick Flow LSX-R 265 Cylinder Heads

Taking both of those rules into mind, Shawn Miller of Virginia Speed, called the guys at Trick Flow Specialties for some advice. After much discussion they decided that the best thing was to provide a set of their TFS 265cc LSX-R heads and let Total Engine Airflow in Tallmadge, Ohio port the head for maximum flow. When TEA and Miller got together, they decided bigger is better on the ports and created what Miller calls the 265 head.

Total Engine Airflow CNC-ported the intake and exhaust runners to huge volumes, and shaped the combustion chambers as well. The flow at .700 lift is an astonishing 368 and 298 cfm.

We offer this head as a casting for cylinder head shops to buy and put their magic into. We call it an ‘X casting’ for extra material. -Cory Roth, Trick Flow

Trick Flow’s Cory Roth said, “We offer this head as a casting for cylinder head shops to buy and put their magic into. We call it an ‘X casting’ for extra material.” The official name is actually the Trick Flow LSX-R Cylinder Head, part number TFS-306003-PC05. Trick Flow’s Mike Downs said, “This is the starting point for the Total Engine Airflow TEA-LS265TF cylinder head for 1997 and later large-bore GM LS engines—the 265cc drag head. It’s our largest offering in a cathedral-port design yet.” He added, “You’ll have to turn the engine a lot of rpm to make up for the small blower, so the 265 head is a good match to really let it breathe.”

After installing copper beryllium seats, they were cut on this Serdi machine to a drag race-only 55-degree seat angle.

Trick Flow’s LSX-R casting has raised spring pockets, rocker pads, and valve cover rails to allow for high-lift cams and valve train components. It is only available in a 6-bolt version. This head is designed for drag race only and uses a competition only 55-degree valve job and titanium intake valves. This creates great airflow benefits at high valve lifts of .700-inch and up. The bare casting has room for obscenely large ports and has a valve angle of 13.5 degrees as delivered, and 64cc chambers.

TFS-306003-PC05 Trick Flow LSX-R Cylinder Head Standard Features

- Material: A356-T6 Aluminum

- Combustion Chamber Volume: 64cc CNC-profiled Standard

- Intake Port Volume: 265cc CNC Ported

- Intake Port Location: OEM

- Intake Valve Diameter: 2.10

- Intake Valve Material: Titanium

- Intake Valve Seat: Interlocking Ductile iron

- Exhaust Port Volume: 85cc CNC Ported

- Exhaust Port Location: OEM

- Exhaust Port Dimensions: 1.700″ x 1.550″

- Exhaust Gaskets: Stock Gm

- Exhaust Valve Diameter: 1.600″

- Exhaust Valve Material: Stainless Steel

- Exhaust Valve Seat: Ductile iron

- Valve Guide Material: Bronze alloy

- Valve Seals: Viton fluoroelastomer

- Minimum Bore Diameter: 4.155″

- Cylinder Head Bolts: OE Length

- Spark Plugs: NGK-TR6

- Valve Covers: OE bolt pattern, raised 0.200″

Miller said, “The 265 is TEA’s race casting. It’s a lot beefier and stronger than the older TFS LS head, which was more of a street head. This one is geared more towards racing. It has six bolts [per cylinder] for LSX and RHS blocks, big 1.650-inch spring pockets, room for bigger pushrods, and just more meat everywhere. Also, it is one of the best cathedral-port heads in existence in regards to flow.” Yes, this is still a cathedral-port head. On the exhaust side they went with what TEA calls the “nitrous port” which features more aggressive porting to flow more air than a standard runner.

It’s true, a cathedral port head can flow huge air. This one does, to the tune of 368-plus cfm at our max valve lift. This is TEA’s optional “nitrous” exhaust port that we opted for. It flows 298 cfm at .700 lift, compared to the standard exhaust port’s 272 cfm.

Total Engine Airflow Head Work

To comply with the original Limited Street valve angle rule, TEA reverse angle-milled the head from its as-delivered 13.5 degrees to 14 degrees. As Downs explained, “That’s opposite from why you normally angle-mill a head, where you decrease the valve angle. We increased it.” When they were done, the chambers came it at 59cc, which when combined with the pistons we were running, brings the compression to 11.3:1.

The TFS LSX-R heads were designed to be used with a GM Performance Parts LSX block, hence they use an extra set of bolts to lock them down and prevent head gasket problems under extreme cylinder pressure.

FLOW DATA (4.155″ BORE)

Lift —- Intake —- Exhaust —- NO2 Exh.

0.100 59 58 55

0.200 128 129 122

0.300 210 189 199

0.400 281 233 250

0.500 340 256 277

0.600 352 267 290

0.700 368 272 298

0.800 377 274 303

0.900 382 277 305

1.000 388 279 306

* Tests conducted at 28″ of water, 4.155″ bore, 2.0″ Exh. pipe

The cam we’re running has a max lift of .777-inch on the intake, .781 on the exhaust, and after hours of porting the ports flow 368/298 cfm of air at .700-inch lift. At .800 lift, close to our max number, the heads are pumping 377 and 303 cfm through the runners. That’s stout for a 388-inch engine.

Ferrea Titanium Valves

Once ported and flow-tested, the TFS heads received copper beryllium seats and Ferrea supplied titanium valves for the intake and stainless valves for the exhaust, all from their 6000 series of Competition valves. As for the titanium intake valves, Ferrea offers some of the finest titanium valves on the market. Their extensive R&D facility is constantly implementing new designs and processes, which continues to stay in the forefront of engine valve technology.

They manufacture each valve by forging a piece of special high-temperature titanium alloy with silicon. The valves then undergo an extensive heat treatment and stress-relieving process to ensure molecular integrity and prolong the valve’s life. “Once we finish the heat treating process we coat the entire valve with CrN coating,” says Zeke Urrutia of Ferrea. “This allows the valve to be used with any type of seat material and guide material.”

The actual valves used in this engine are part number F6302 on the intakes, which is a 2.100-inch valve head with an 11/32 stem and .250 tip size, and 4.910 inches long. Exhausts are part number F6305, with 1.600-inch head, 11/32 stem, and also 4.910 inches long. The intakes have a 10-degree backcut, and the exhausts are 12-degrees.

Each Ferrea titanium valve is meticulously machined in their own precision CNC machining center where it must pass extensive quality control procedures.

As far as the stainless exhaust valves go, Ferrea’s “super alloy valves” represent what they claim to be the highest level of sophistication in valve technology. Ferrea introduced the next generation of extreme heat resistant valves, specifically developed to withstand the brutal punishment of NHRA Top Fuel and Funny Car applications. They have developed a specially processed high nickel-based alloy, and a unique heat-treatment process, which yields extreme heat resistance and enormous tensile strength properties (far beyond conventional Inconel materials).

Comp Elite Drag Racing Dual Valve Springs

Controlling the valves at 9,000 rpm, big lift, and high cylinder pressure is not the job of wimpy springs, so Virginia Speed went to Comp Cams for their Elite drag race dual 1.500-inch diameter valve springs, and set them up with 350 pounds of pressure on the seats, and a stout 950 pounds when open. Miller really wanted to use Comp’s lightweight titanium retainers, but at the time the engine was built, Comp didn’t offer them for these springs. Manley titanium retainers were chosen.

When asked about that spring pressure, Miller said, “Forced induction likes a lot of seat pressure. It’ll float the valves really fierce at higher rpm and higher boost. We’ve had fewer problems with excess [pressure] than not enough.”

High rpm and lots of boost means you’ve gotta run a lot of spring, and we handled that with Comp Cams’ Elite Drag Race dual springs with 350 pounds on the seat and a whopping 950 open.

Jesel Rocker Arm Setup

The rest of the valvetrain consists of Jesel’s trick shaft rocker setup for the LS heads, as well as their keyed lifters riding on a custom Comp camshaft and pushing ½-inch diameter pushrods, while a Jesel belt drive connects cam to crank. The valvetrain parts we used with these heads were explained in detail in a previous installment of our 388 LSX’s build saga.

At this point, you may be asking how much coin you have to shell out for these heads. Well, with any race engine, how much you spend is often directly proportional to how fast you go. In this case, the price tag isn’t offensive. The TFS/TEA heads retail for $3,950, which is really chump change for the amount of power they are set to deliver.

Forced induction likes a lot of seat pressure. It’ll float the valves really fierce at higher rpm and higher boost. -Shawn Miller, Virginia Speed

Putting It All Together

Clamping the heads to the LSX block are ARP studs and sealing the block-to-head interface are SCE copper gaskets. Why copper? Miller said, “LS engines inherently have head gasket issues, because of the way the bolt pattern is. There are 10 bolts from the factory, and even with the LSX block with the extra head bolts, they’re a good distance away from the bore. They don’t have the same clamping effect as on a small-block or big-block Chevy. There’s a lot of guys running MLS [multi-layer steel] gaskets on the LS and still having head gasket issues.”

In addition to the copper head gaskets, Virginia Speed installed double O-rings, one in the block and one in the head, to seal combustion pressure. Silicone was used around the water ports, and otherwise the gaskets were installed dry, with no other sealant. “We’ve made over 2,500 horsepower on an LS with these gaskets and had no issues,” said Miller. Street guys listen up: you don’t want to run copper gaskets on a street car, as the constant heat cycles in a street application will eventually create a water leak from the gasket.

The head gaskets are no-compromise SCE copper gaskets, designed for a tight seal under extreme cylinder pressure.

What’s Next For the 388 LSX Bullet?

Over the last few months we’ve bolted the whole combo together with our our F1-R ProCharger, dropped it in Project BlownZ, and made some very respectable low 8-second passes. In the next installment we’ll outline how we tuned the 388 LSX on both the track and the dyno. How much power did it make? You’ll just have to wait and see.