Here we are, staring another Thursday with an editorial throwback. The week is almost over, and once again, we open the vault that houses our vast collection of articles. This time, we’re taking a step back in time to locate an article that you guys might have either forgotten about, or might not even know exists. Whichever the case, we are certain that you will enjoy this editorial flashback.

Dart’s LS Next2 billet block is designed from the outset to withstand the rigors of serious competition. The bare block received a set of sleeves to accept Diamond hard-anodized pistons.

I decided that this week, we should take a look back to just a few years ago, October 2015, and visit at an article that all gearheads can enjoy – The Head To Toe Billet LS Next² Engine Build With Late Model Engines.

Showcasing this powerhouse build, our Intrepid Jason Reiss talks to Late Model Engines‘ Bryan Neelen about the LS engine build that would be perfect in any hot rod looking for a little, okay, a lot of tire frying power. Sure, it might be overkill for some, but we know you power junkies will really dig into the information provided in the original article.

The GRP Pro Series billet aluminum connecting rods ride on coated Clevite bearings, and the hard-anodized Diamond pistons are suspended on DLC-coated Trend TP-1 pins and wrapped in application-specific Total Seal M2 piston rings.

I don’t want to give away too much information, you’ll have to read the original article for complete engine specifics, but suffice to say, with an LS Next² engine block, a large by huge Procharger, a billet crankshaft, billet-aluminum connecting rods, Diamond Racing pistons, and a myriad of other go-fast goodies.

Making power requires proper valve-movement and control. Although the specifications on this particular camshaft aren’t disclosed (wink-wink), the springs are installed at a 2.200-inch height. Assembling an engine like this requires more than just throwing parts together, and Jason gets input from the professional. “We also like to physically measure the net lift of the cam during mock-up. This means measuring cam lift with the actual springs, rockers, and pushrods being used. This allows us to take rocker and pushrod deflection into account. Having this information on hand allows us to tweak the installed heights on the springs for optimal coil bind distance. Optimizing the spring heights can increase RPM capabilities, improve spring life, and reduce spring failure,” Neelen explained.

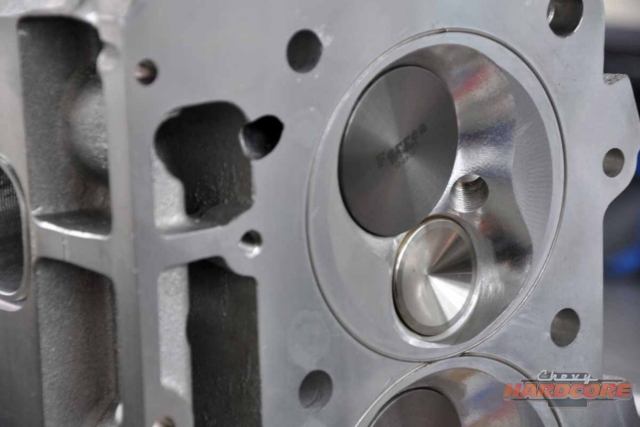

The Edelbrock LS-R combustion chamber softening performed by Race Flow Development can be seen here; it’s the shallow hemispherical cut from the outer edges of the bore towards the combustion chamber’s roof. Titanium Ferrea intake and exhaust valves are installed to combat the immense heat of the supercharged combination. RFD’s Curtis Boggs tailored the intake and exhaust ports for optimal performance. Combustion chamber volume is set at 52cc.

Jason also gets in-depth about what it took to make the Edelbrock cylinder heads deliver the flow needed. One of the modifications done is called chamber softening, and the original article goes into detail about that process. In a nutshell, it has to do with cutting into the chamber.

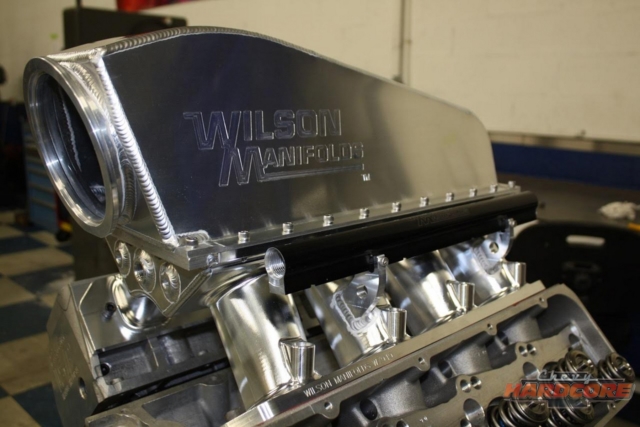

More jewelry appears on the top side of the engine, where the combination billet/sheetmetal intake manifold from Wilson Manifolds was designed to provide balanced airflow to all cylinders.

An engine like this isn’t going to produce a lot power if the wring induction system is used, so Mr. Reiss goes into more detail of what parts were chosen, and how they were designed to build power. If you are looking for an in-depth look at the headers and the installation of the aforementioned Procharger, Jason even links back to an article explain the header building process.

ProCharger’s F-series supercharger has proven itself in hundreds of street-car races all over the globe.

There is no surprise that the components used in this build are the very best of the best. The guys at Late-Model Engines don’t cut corners during the design and implementation of an engine program. You want proof? Find out more by reading The Head To Toe Billet LS Next² Engine Build With Late Model Engines.