Even though a crankshaft is a beefy chunk of metal, it is subject to constant twisting forces that can result in tremendous vibrations. Since the crankshaft has a natural resonance frequency like any other metallic object, those vibrations could match up with the crank’s inherent resonance. At that point, the vibrations are enhanced significantly, almost like giving a child on a swing a push at just the right time to send him a little higher. Left unchecked, that energy will build up in the crankshaft and lead to a structural failure.

Even though a crankshaft is a beefy chunk of metal, it is subject to constant twisting forces that can result in tremendous vibrations. Since the crankshaft has a natural resonance frequency like any other metallic object, those vibrations could match up with the crank’s inherent resonance. At that point, the vibrations are enhanced significantly, almost like giving a child on a swing a push at just the right time to send him a little higher. Left unchecked, that energy will build up in the crankshaft and lead to a structural failure.

Too much twist and rebound, the result of a worn out or mismatched damper, can result in a broken crank.

The worst twist will always happen farthest away from the greatest load. In other words, as the crank is being twisted, the level of twist is worse at its ends. At the rear of the crank is a heavy flywheel/clutch assembly (or flexplate and converter) that helps absorb some of the twist, and mounted to the front snout of the crank is the damper that absorbs and counteracts as much twist as possible. A damper (sometimes called a harmonic balancer) is made of two elements—a mass and an energy-dissipating element. The mass element resists the acceleration of the vibration and the energy-dissipating element (inertia ring) absorbs the vibrations.

There are options in damper design and construction that builders can select from when assembling a performance engine. Three of the most popular damper manufacturers are ATI Performance Products, Fluidampr and TCI.

Dampers should always be installed and removed with dedicated installation tool; never with a hammer or just the damper bolt.

With the proper damper on the front of the crank, the majority of the twist can be controlled or eliminated, but the wrong damper will allow this twist to be uncontrolled or even magnified. Racers will put a ton of thought into nearly every component when building a performance engine, but they rarely put much thought into the damper.

The OEMs generally source an elastomer style damper that uses a rubber compound material bonded between the crank hub and an outer inertia ring. The crank hub turns the same speed as the crank and it transmits the resonance through the rubber and into the inertia ring. The inertia ring “floats” back and forth, absorbing the resonance. The dampers are “tuned” to a specific frequency range, depending on the engine and its application. Even the same engine in different vehicles may receive a damper tuned to a specific driving style.

The volume of OE manufacturing dictates a compromise that works for everyone, but let’s say you bolt a pair of turbos to your stock Camaro—you better consider replacing the stock damper to a performance damper that can better absorb the different level of torsional vibration you just put on the crankshaft. Following is a brief review of products from ATI, Fluidampr and TCI along with a round table discussion with their technical experts to answer questions and offer performance-enhancing tips.

ATI Performance Products

The OE dampers use a rubber-like O-ring bonded between the hub and the inertia ring, tuned to a specific frequency from the factory. Age, abuse, and exposure to the elements will eventually break down the rubber and either cause the outer ring to move (hence throwing off the timing marks) or simply stop the absorption process. ATI utilizes several different O-rings in the same damper.

ATI’s Super Damper uses a steel hub that attaches to the crankshaft snout, an inner shell made of either aluminum or steel (depends on application), and a steel inertia weight that has six (2-ring design) or eight (3-ring design) computer-machined grooves to retain the proper durometer O-rings, which are dyno-tested for each application.

“With the ATI Super Damper, we have a smaller diameter and a larger diameter of elastomer. We can change the stiffness of the elastomer in either of those areas to accommodate low torque range and then high-frequency high-rpm running,” explains ATI’s J.C. Beattie. “We are also not limited to one hardness or one type of elastomer for dampening. We can use different hardness and materials in the small and large part of the damper to accommodate the entire range of running, or tune the damper to perform in a very narrow rpm band.”

Since OE dampers have the elastomer bonded in place, when it fails it’s not rebuildable, whereas ATI’s dampers are much more carefully machined and built, the elastomer is not bonded in place, and they are therefore are fully rebuildable.

Fluidampr

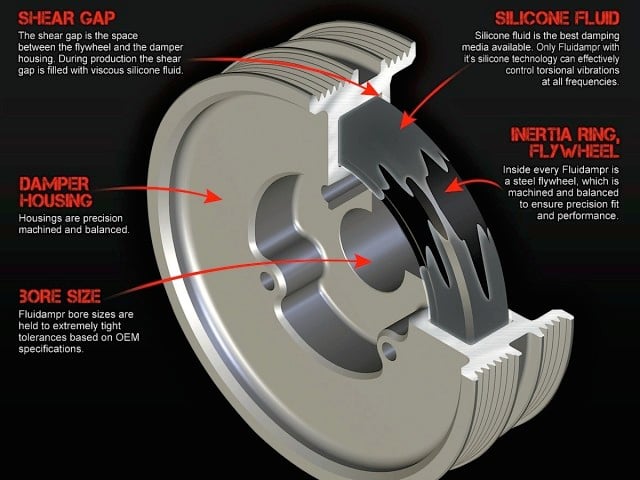

As the product name implies, Fluidampr performance dampers replace the typical elastomer ring with viscous silicone.

“Viscous style dampers, like Fluidampr, are commonly used in commercial, industrial, aerospace and defense applications for their broad frequency coverage and superior durability,” says Fluidampr’s Brian LeBarron. “Inside a sealed housing is a free rotating inertia ring encased in a thin layer of specified viscous fluid. Crankshaft rpm and vibration causes the outer housing and inner inertia ring to move in and out of phase with each other, and the resulting shearing action through the fluid transforms the vibration to heat and dissipates it through the outer housing surface. Since the inertia ring and housing are not bonded and limited in their reaction and movement like an elastomer design, a viscous damper can become more effective with greater vibration amplitudes.”

TCI

TCI’s Rattler damper, which the company’s refer to as a torsional vibration absorber, is a pendulum-type design that uses steel rollers loosely fit into holes inside the damper body. The rollers roll forward during compression strokes and backward during the power stroke to minimize the engine speed variations and vibrations. TCI says that one of the advantages of the Rattler is its effectiveness at all engine speeds and not just a specific range. Will Vance, Sales Technician at TCI, says the main advantages of the Rattler damper are that it won’t wear out and it can withstand heat without failure or degradation in effectiveness.

TCI’s Rattler absorbs vibrations through a set of counterweights whose natural frequencies are directly proportional to the speed of the crankshaft. It looks like a traditional damper on the outside, but works by the centrifugal force of the rollers that ride on the outside wall of the absorber’s body.

Great tips from the experts!

Whatever decision you make when choosing a damper design, the most important consideration to remember is that the vibration damper, or harmonic balancer, or whatever you call it should always be considered when building an engine or changing an engine combination. Just like sticking a huge camshaft into an engine is only effective if you consider things like the torque converter and gearing, changing the engine’s operating range and/or power requires some real thought about matching the proper damper to the new combination.

EngineLabs posted five questions to tech experts at the three damper companies. Those quoted here include J.C. Beattie from ATI, Brian LeBarron from Fluidampr and Will Vance from TCI.

EngineLabs: Not to start any trash talking, but tell us why you recommend using one of your dampers over your competition?

Definitions and Terms

- Torsion: The application of twist without any bending producing a pure torque.

- Torsional Vibration: Variations in the torque transmitted.

- Frequency: The number of vibrations, cycles or waves of a periodic phenomenon per second.

- Natural Frequency: The frequency of a free vibration.

- Free Vibration: A vibration with periods depending solely on the properties of the disturbed system.

- Resonance: The synchronism of a harmonic of a forcing impulse with the natural frequency of vibration of a mechanical system, usually leading to excessive amplitudes of vibrations.

- Order Number: The number of vibrations or impulses, which occur per revolution during the torsional oscillations of an engine crankshaft.

- Damper: A device for dissipating energy in a mechanical system by the suppression of vibrations of unfavorable nonlinear characteristics.

- Harmonic Damper: A rotating or oscillatory mass that is designed to produce forces opposing the out of balance forces in the reciprocating engine or transmission systems.

- Tuned Torsional Vibration Damper: A flywheel coupled to a shaft by a spring to form a resonant system effective at frequencies near its natural frequency.

Courtesy of ATI

LeBarron: Make your decision based on quality, not lowest price, because a damper ultimately helps protects your entire engine investment. Fluidampr, a viscous style damper, is among the very highest quality because of its superior durability, effectiveness, and protection across broad frequencies and multiple orders of torsional vibration throughout your rpm range. This means with a Fluidampr installed, owners can keep making future modifications without worry and the costly need to replace or retune their harmonic balancer. During the mid-1980s, at the request of professional engine builders looking for a better alternative, we took our proven viscous damper technology used in much longer life, higher power industrial, commercial and military powertrain applications and enhanced it for street performance and motorsports use. Since, Fluidampr has been race-proven for over 25 years. No longer stereotyped to low-rpm diesel engines, today Fluidampr performance dampers can be found protecting 8,000+ rpm V8 circle track cars and 10,000-plus rpm inline fours, in addition to incredibly powerful diesel pulling trucks. Last, Fluidampr is made in the USA.

Vance: They do not wear out nor do they leak, since there exists not rubber/elastomer, and not liquids. You can get them as hot as you like or make them work as long as you wish. The OD moves at the same radial position as the crankshaft, unlike most balancers, since the Rattler has floating weights inside.

EngineLabs: When do you use a steel shell, and when aluminum?

Beattie: We like to use steel dampers on engines that will run for many years, street cars, and very high HP engines like A Fuel dragsters. We like aluminum shells and steel hubs on boats, off-road trucks and road race engines to keep any excess weight off the nose of the crank. And all aluminum dampers and hubs on drag race engines mainly, as well as some modified and sprint engines.

LeBarron: Damping torsional vibration requires adequate mass and heat cycle properties if it’s going to protect your engine for any extended period of time. Aluminum may be lighter and it may help you rev up faster, but it is not as effective at controlling torsional vibration over time as compared to steel.

Vance: Aluminum would only be a consideration if weight is an extremely important factor. Truthfully, aluminum is not a popular choice.

EngineLabs: Is there a difference between a street and a race damper? Meaning, do you have a one-size-fits-all performance damper, or are there several designs depending on the engine’s use and components?

Beattie: All of our dampers are SFI approved. With my 20 years of testing and all of ATI’s years of building the damper, we have a very good idea of what is needed to be the right damper the first time right off the shelf. We have roughly 420 different damper part numbers that we stock, and another 400 that we can build from them and another 1,500 custom files for dampers we have made, from Fiat to Ferrari and Oliver Tractor engines to Briggs and Stratton.

LeBarron: Fluidampr offers a value-priced line of non-SFI rated Streetdampr brand dampers for popular small block Chevy and Ford applications. Streetdampr products can be used from mild to heavily modified applications whenever SFI 18.1 specs are not required because they provide similar benefits of broad range protection coverage and superior durability as Fluidampr just without a final protective finish. With some select applications we also offer different diameters and weights. It’s a compromise; a larger, heavier damper will provide more damping but slower throttle response and a smaller, lighter damper will improve throttle response but provide less protection. It is always best to consult with your engine builder or damper manufacturer if you need assistance.

Vance: Sometimes they cross over, but there are various options, sizes, and types—more specifically offered to satisfy specific niches.

EngineLabs: In the same vein as the above question, with a high-powered engine that sees both street and race action (such as Hot Rod’s Drag Week), is there a compromise involved when it comes to a damper?

Beattie: For something like that we err on the side of too much damper, meaning more weight instead of less. For a big horsepower Drag Week car, I would do a steel hub and an aluminum shell damper. It won’t see the miles of an actual street car, but it will see the hard runs down the dragstrip and an aluminum-shelled damper with a little less weight will help out the combination. The internal inertia weight is what does the dampening work and that stays the same weather it’s a steel or aluminum damper.

Fluidampr provided this handy illustration to help explain the twisting that happens to a crankshaft during engine operation. Absorbing the constant twisting and rebounding of the crank is the job of the damper.

LeBarron: Our belief and what our customers tell us is that they would rather want race-level protection on the street and not need it, than risk the reverse scenario at the track. For these owners, where an SFI 18.1 damper material spec is not a prerequisite, there are no compromises between Fluidampr or Streetdampr because of its viscous-style design. Both will provide the broad range of protection throughout the entire rpm range.

Vance: Usually the compromise results in conceding that the crankshaft will eventually fatigue and fail. In some extreme racing cases, this is an approved compromise.

EngineLabs: Let’s say I have a 500-horsepower Gen I small-block Chevy and add a turbo to make 1,200 horsepower. Assuming the rotating assembly is not changed, should I change the damper, or are they not that specific?

Beattie: You just increased your cylinder pressure a bunch. Therefore the crank is getting hammered that much harder on the power strokes and forcing it to torsionally twist that much more. When you add power, you need to upgrade other parts. Did you upgrade your transmission and clutch or converter? How about your driveshaft and rearend? Axles? Tires? Well the damper is usually overlooked but it should be on your list as well! It’s at least worth a call to ask about it since hurt bearings or a broken crank is way worse than busted rearend.

LeBarron: It depends on what damper you currently have installed. If it is a stock style, then yes absolutely upgrade the damper. If you already have a Fluidampr performance damper installed there is no need to change or re-tune the damper because of its viscous-style design.

Vance: There are more details to consider, such as what rpm range is being targeted. And going from 500 horsepower naturally aspirated to 1,200 horsepower forced induction is never going to happen without at least a piston change, so I think yes, plan for getting the right balancer for the change.