We all know a drag race is an acceleration contest between two cars. These short-burst competitions have been going on for as long as anyone can remember. The contest begins when each vehicle lines up at the starting line, and they both leave when the light in their lane turns green. The first to the finish line wins.

It’s a simple premise, but there are still plenty of enthusiasts that have never partaken in the enjoyment of blasting down a quarter-mile in their hot rod. At a lot of shows held at racetracks, show participants are given the opportunity to make a pass down the track. Unfortunately, many decide not to experience the thrill, because they don’t feel confident their equipment is up to the task. To help you make sure your hot rod is track-ready, we decided to put together an unscientifically compiled list with the help of Moroso Performance Products. The following are just a few small details you might want to consider so your hot rod will be ready for a little track time at its next quarter-mile showing.

Every car must first pass tech inspection before it can make a run down the track. We are not talking about certified race cars, so a general safety check might be on the menu. This could include: checking for functioning brakes, verifying that the brake lights work, checking the steering for excessive play, checking the driver seat for solid mounting, looking for loose objects (clothes, tools, and so on).

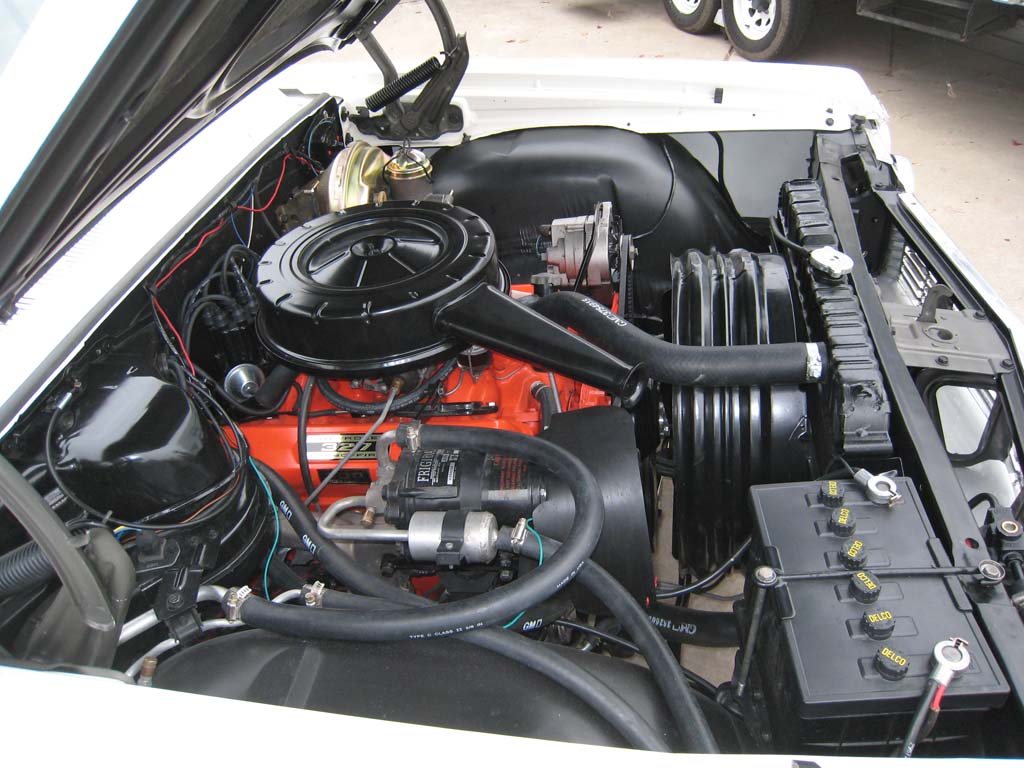

Many hot rodders have built their cars for the enjoyment of going for drives around town and to shows. They do not get overly concerned about adding stuff to their car to make a better race car. But, while at a show that offers the opportunity, some decide to try it once to see what all the hub-bub is about. For many though, once that first pass is completed, they usually ask what they need to do to their car to make it better for the purpose of racing.

Those making plans to do so, usually ask what’s next in the list of required upgrades for their car to make it safe and reliable while making the 1,320-foot trip. That’s where we come in. We checked with a couple of other resident racing regulars in the Power Automedia office so we could compile our list, giving new enthusiasts insight into some of the things they might want to consider if making an occasional quarter-mile blast.

If your car’s battery is in the stock location, the factory hold down will likely be sufficient for the tech guy, if it’s in good condition. If your battery is mounted in the trunk, you will probably need to check the NHRA rule book for guidance.

There are too many factors that need to be considered for this to be a comprehensive compilation. For that reason, we are focusing on information that would be helpful to those enthusiasts who are just getting into the enjoyable scenario of blasting their car down the race track. In other words, those just getting started. We are fairly certain a first-timer doesn’t have a car that is NHRA-certified to make the trip in under 9- or 10-seconds. For that reason, let’s just take into account those classic cars that trip the win light at times no quicker than 12.50 seconds in the quarter-mile.

Safe Passage

Whether racing or not, safety should be first-and-foremost on your mind when you’re behind the wheel. For that reason, we’ll start our suggestion list with that in mind. The following items are required for any vehicle and driver needing to pass tech: tires that are in good shape, a quality battery hold down, radiator overflow reservoir, functioning neutral-safety switch, seat belts, and a valid driver’s license. The driver must wear long pants, closed-toe shoes, and a shirt. Some tracks might even require all drivers to wear a helmet, no matter what e.t their car runs. And, you may also find tracks that prohibit anything but plain water in your cooling system, so check if you aren’t sure.

If your car was built before the government mandated seatbelts, you will need one in order to make a pass (all people in the car should have one at all times anyway). All cars must be equipped with an accepted quick-release-type driver seat belt. The OE belt is sufficient for the e.t.’s upon which we are focusing. If your show car does have a racing harness employed, keep in mind, they are not DOT legal.

A Leaky Proposition

If you don’t think a small engine leak is a big deal, think again. An untold number of crashes occur at every event because fluid gets between the car’s tires and the track. That is why all tracks are adamant about there not being any “engine sweat” dripping from under the hood. If your engine is leaking, maybe it’s time to check items like the valve covers, rear main and front engine seals, or the oil pan. A quality gasket can go a long way to keeping your engine’s fluids where they belong.

While Moroso’s universal, polymer overflow container will work, PN: 63655 is an aluminum container that is a great looking upgrade. Whichever you choose, one will be required.

Although not often given much consideration, many classic cars didn’t come with an overflow containment system for the radiator. Without a “catch can,” as the engine coolant is heated and cooled, the level in the radiator fluctuates. When the engine gets hot, the rising coolant level results in excess liquid being expelled out of the overflow vent tube under the radiator cap. If there is no catch can, that fluid spills onto the track. A simple catch can is easy to get and install. In fact, Moroso has a universal overflow canister (PN: 63657), that sells for a measly $41.79. Even if you’re not racing, why wouldn’t you already have one on your car?

Pedal Problems

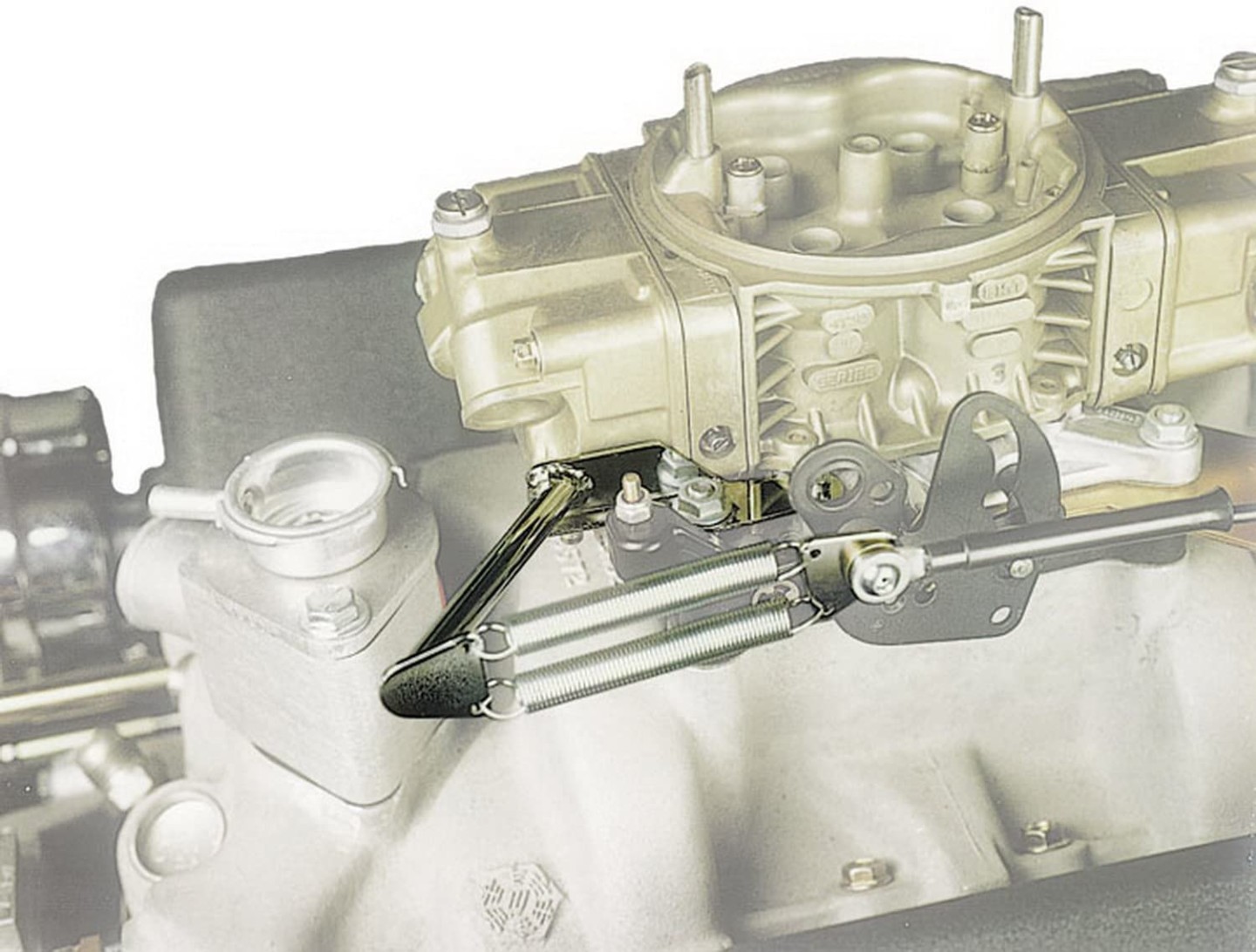

Have you ever had the throttle “stick” while driving your hot rod? Imagine that happening while you have the pedal pressed against the floorboard. Having a double throttle return spring system might not be required by some tracks, but it is definitely a great piece of insurance to have. In fact, PN: 64927 costs around $30.00 and not only offers piece-of-mind, but it also looks great on any engine.

Flexible Flyer

If you’re driving a Camaro, Firebird, Nova, or other X-body, then you know all about unibody cars. While the unibody design is not a bad way to build a car, it does, however, need some help when upgrading the performance aspect of the vehicle. Whether you are at the track or just driving around town, subframe connectors are not a bad item to have on your car.

There are two styles of subframe connectors: bolt-in and weld-in. When looking into connectors, there are a few things to keep in mind. With a weld-in style, you might need to cut the floorboards and/or factory-subframe rails. While this sounds like a hassle, it is the best way to ensure a solid foundation. This process keeps the connectors tucked-up as close as possible to the body. If a welder is not available, then bolt-in connectors are your next option.

When choosing subframe connectors, you can either get a bolt-in style (top) or a weld-in style (bottom). The initial cost of buying a weld-in connector is less than a bolt-in style, but if you have to pay someone to weld them in, the cost will go up.

Some say a bolt-in frame connector is less effective because they aren’t rigidly secured to the vehicle’s chassis. It’s understood that there’s still room for some flex because welds aren’t used. Bolt-in connectors, however, are easier to install and are sometimes more affordable if you take into consideration needing to pay someone to weld them in place. Obviously, the OE subframes will have to be modified in order to run bolts through them, but nothing will have to be cut apart.

Getting Loopy

If you have ever seen a car or truck break a U-joint and spit the driveshaft out, you know the damage it can cause. That’s why the NHRA requires the use of a driveshaft loop if a car is running 13.99 seconds or quicker while on slicks or 13.00 seconds or quicker while running street tires. The rules require the loop to be mounted within 6 inches of the front U-joint on the driveshaft so as to support the driveshaft in the event of a U-joint failure. Installing one of these safety devices is not difficult and should be a consideration for anyone – especially you manual-shift guys. Competition Engineering’s PN: C3028 is a universal design that can be made to fit virtually any classic hot rod.

Hopefully, this list can help you prepare your car for its first trip down the quarter-mile. What it will not help you prepare for, is the overwhelming urge to do it many more times afterward. But that’s what this hobby is all about; finding out what makes you happy, and doing it to the best of your ability. Now, get out there and have some fun.