Drag racing is an elusive sport. What once was a simple hobby can quickly turn into a new lifestyle, wherein you spend untold amounts of money, time, and effort to be competitive. Some enthusiasts are drawn to drag racing because of competition against man and their machines, but the sport can also be about friendship and family. It’s a hobby that everyone can go and enjoy, plus there is always a task that needs to be accomplished. Whether it’s refueling the car, bolting on a hood, or just pushing it to the staging lanes, help is always appreciated at the track. For Travis Martin, a maintenance manager out of Fort Wayne, Indiana this was definitely the case.

When Travis started tinkering with cars at the age of 16, like most of us he didn’t have a background to lean on— but passion fueled his interest. He was around cars most of the time and had experience from working at a car dealership and a quick lube, but other than that he was self-taught. He learned some things the easy way and some the hard way, but he never lost interest in the automobile and the art of making them go fast. Travis stated, “I have always enjoyed the technical side of taking something, making it my own, and performing better than before.”

What started out as a hobby with his friends at the dragstrip has turned into something much more significant with the passing of time. Travis said, ”Friendship has always attracted me to the race track and hanging out with friends. My love for racing has actually become a family affair.” Currently, his wife, Amanda, has a 2009 Pontiac G8 that she loves to race in the 11.50 index classes and many of their friends and extended family they’ve met through racing over the years.

Travis purchased his 2001 Camaro Z28 from Dehaven Chevrolet in Fort Wayne, Indiana his freshman year in college in 2003. After he had totaled out a ’99 Camaro Z28, he simply needed a replacement car for getting around, and it seemed natural to buy another white Camaro. Travis has owned three Camaros and it’s safe to say he is definitely a Chevrolet and Camaro guy. This super-clean Z28 has come a long way even though the odometer only reads 34,000 miles, and it appears as fresh as the day it rolled off of the showroom floor. When asked what his favorite thing about this particular car Travis replied, “I really like that it’s still 100-percent streetcar.”

When I set out to build this car it was with the full intention of making a low 8-second street car which retained many of the factory creature comforts,

The idea behind the build on this Camaro was a pretty simple concept that is complex in design.

”When I set out to build this car it was with the full intention of making a low 8-second street car that retained many of the factory creature comforts, ”Travis explained. This Camaro could pass any day of the week as an actual street car and considering that he has made it through not one, but three Drag Week competitions say an awful lot about this build and the success of Travis’ venture. This street car still retains most of its creature comforts like keyless entry, power steering as well as power brakes. It’s an 8-second race car, and according to Travis, it can be driven anywhere in the country.

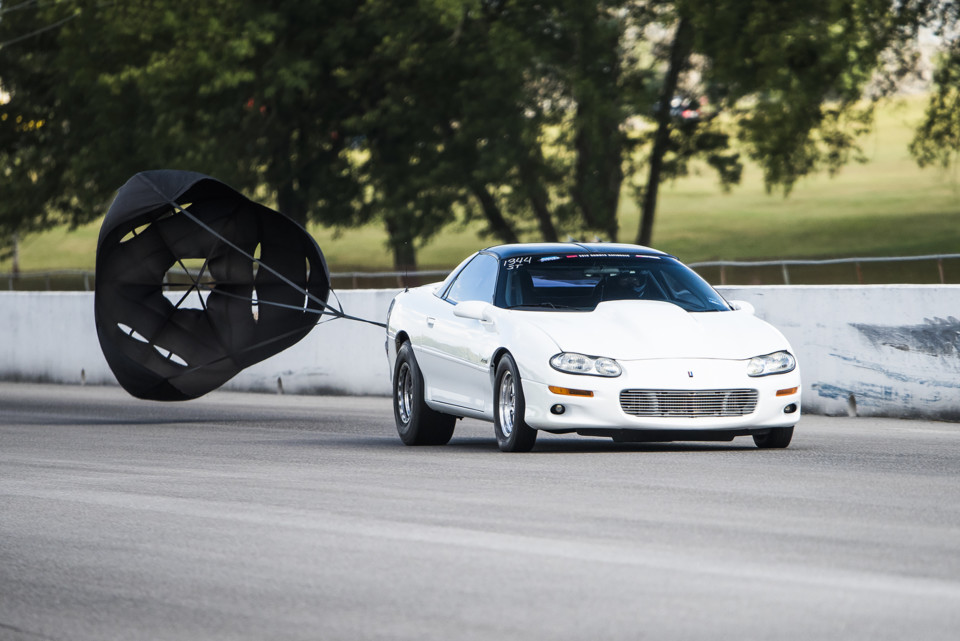

With the intent of building a real “sleeper,” Travis made sure that no particular part of this build would stand out as a racecar. All of the factory latches including the hood were reused in the build instead of having hood pins and a large oversized hood. The Camaro does have full exhaust with boost activated cutouts that extend out to the axle—honestly it’s nice not to see a fender or bumper exit exhaust on this car. The parachute even comes off, and a flip-up license plate covers the mount that ties into the car. According to Travis, ”A great amount of time was spent to lay everything out to do this. I take great pride in the fit and finish of items as well as the performance of the car.” It definitely shows in the subtleness of this build and the fact that the Camaro does indeed hit the 8-second mark.

While we aren’t entirely convinced that this car is a “sleeper,” if you removed the tires and wheels and parachute hanging off the back of the car, it could definitely pass as an overly built 10-second car. But a sleeper? That might be a little bit of a stretch especially when you start looking closely at the build.

Travis ditched the factory 364 cubic-inch engine and replaced it with a 402 cubic-inch version stuffed with Callies crankshaft, Wiseco pistons, and Callies Compstar connecting rods. This resulted in a 4-inch bore, 4-inch stroke and a compression ratio of 9.5:1. The engine was built by Dustin Portmess of Fort Wayne, Indiana and he handled honing the cylinder walls, balancing the rotating assembly, gapping of the rings, verify bearing clearances, and all of the other essential machine work. On the bottom side of the 402, a Melling oil pump was used along with a Moroso oil pan to seal the deal. The camshaft consists of a hydraulic Crane custom grind with a lobe separation of 115. A set of Lingenfelter Performance Engineering LSA aluminum cylinder heads fit the bill and housed 2.165-inch diameter hollow stem intake valves and 1.59-inch diameter Inconel exhaust valves. To finish off the valvetrain, the stock LS3 1.7 rockers arms were deemed sufficient and have held to the rigors of street driving as well as racing.

For induction on the 402, Travis decided to use a Shaun’s Custom Alloy billet intake manifold with a set of 80 and 160-pound injectors with a Nick Williams 102mm drive-by-wire throttle body. Stock truck exhaust manifolds were utilized for the hot side, and the 2.5-inch piping delivers the exhaust to a pair of Forced Inductions 72mm turbos with 3.5-inch downpipes, Tial Sport wastegates, and Tial blow-off valves. The cold side of the turbo system consists of 2.5-inch piping and a custom 6-inch Bell Core air to air intercooler to keep things cool. This combination with 34-pounds of boost is controlled by a Holley Performance Products Dominator ECU, and with the help of Chris Bishir, the two are more than capable of keeping a handle on this beast.

If you are going to run eights and participate in Drag Week, you better have a drivetrain and suspension that will take some strenuous abuse. Not being one to overlook the details, Travis went with RPM Transmissions out of Anderson, Indiana for a built TH400. The TH400 employs a Reid Racing transmission case, billet valve body, pro transbrake, and a 4200 rpm stall speed converter from Neal Chance Converters. A Russell Performance brand transmission cooler keeps the transmission temperatures at bay while the car is on the transbrake in the beams. The gear shifts are handled by a TCI Outlaw shifter while the power is transferred to the Stange Engineering 12-bolt rear-end with 35-spline axles, a spool,and 3.08 gears, via a 3-inch Strange chrome-moly driveshaft. The chassis for the Z28 is comprised of all of the fourth-gen goodies from BMR Suspension like upper and lower control arms, subframe connectors, pan-hard bar, torque arm, driveshaft loop, and an Extreme anti-roll bar. Menscer Motorsports was called on to handle the dampening duty both on the front and rear of the car.

The exterior of the Camaro still flaunts the factory Arctic White factory paint job with the addition of an SS wing and VFN Fiberglass Sunoco hood painted to match. The only other real mods to the outside are the Wilwood brakes and the addition of the Billet Specialties Street Lite wheels. The front wheels are 15×3 while the rears measure 15×10 wrapped with Mickey Thompson 275 Radial Pro tires. The stock theme doesn’t vary too far when you look at the interior either. The Z28 still has the full factory grey interior with the addition of a Midwest Chassis Cage certified for 8.50’s and the Holley digital dash.

All of this dedication and hard work has netted Travis a best 1/4-mile time of 8.24 at 173 mph so far. The Camaro’s best sixty-foot time is a 1.37, and the car makes an estimated 1,250 horsepower and 1,100 pound-feet of torque to the wheels. Travis is quick to thank his wife, Amanda, for letting him do what he loves, the Team260 Family, and Chris Bishir for all of his help with the build, tuning, and endless knowledge.

We will continue to keep an eye on Travis and what he calls his “100-percent streetcar” to see what he will be doing next. With the amount of dedication and detail in the car, the past has shown that it is only going to get faster in the future.