Autocross events are not where you’d typically find a fourth-generation Chevrolet Camaro lurking, but the SCCA takes pride in inclusion. The staging lanes of the cone-littered parking lots are typically a sea of Miata’s and Corvettes, sprinkled with random daily drivers, spending 30-45 seconds dodging cones in a make-shift arrangement simulating a road course. But Scott Cordell’s 2002 Camaro breaks the mold and presents a corner-carving monster and worthy competitor.

Photos By: Brian Wagner

Scott is no stranger to taking corners; his youth spent on kart tracks sliding his chassis around enabled him to have more skill behind the wheel. He carried on his father’s kart racing legacy by competitively racing from age 8-16. He won multiple Yamaha class championships in 1994 and 1995. When not pushing the limits at the kart track, he could be found with his grandparents at various dirt and short tracks watching late-models, and sprint cars duke it out.

As with most racers, turning wrenches is not only a money saver but also a learning experience. Scott is no different, as he learned how to wrench at an early age through a family tradition. His family has a four-generation lineage of automotive technicians that provided him a clear path, And this mechanical pedigree has led him to become a GM World Class Technician and spawned a love of F-body cars. This is an infatuation that his wife took note of when secretly trading in her daily driver to surprise him with the car of his dreams.

The Dream Chevrolet Camaro

In 2003 an Arctic White Chevrolet Camaro appeared on a local dealership lot after being traded in; its bone-stock LS1 motor remained unmodified, and the automatic transmission was still in place. The black leather interior was still in mint shape with minimal use. Scott’s wife, Tricia, knew this car would be the perfect platform for her husband’s ultimate build. Scott’s background and occupation would later prove that was true.

Making Power

Scott specializes in engine driveability and performance for a living, so naturally, the first step was to upgrade the stock 345 horsepower lump with something much more potent. He first contacted Texas Speed and Performance in Georgetown, Texas. An oversized Gen IV 6.0-liter block filled with Texas Speed’s finest would soon be en route to its new home.

The block was bored to 408 cubic inches, and to start a firm foundation, ARP main studs were threaded in to keep the main bearing alignment in check for the Texas Speed crankshaft. Wiseco pistons attached to Texas Speed 6.125-inch H-beam rods were dropped in, creating a stout bottom end ready for boost. ARP head studs keep a pair of aluminum Texas Speed cathedral Port 225cc heads from departing from the block on the top end. The massive heads utilize 68cc chambers and allow maximum airflow at increased RPM. A Texas Speed hydraulic camshaft ties it all together.

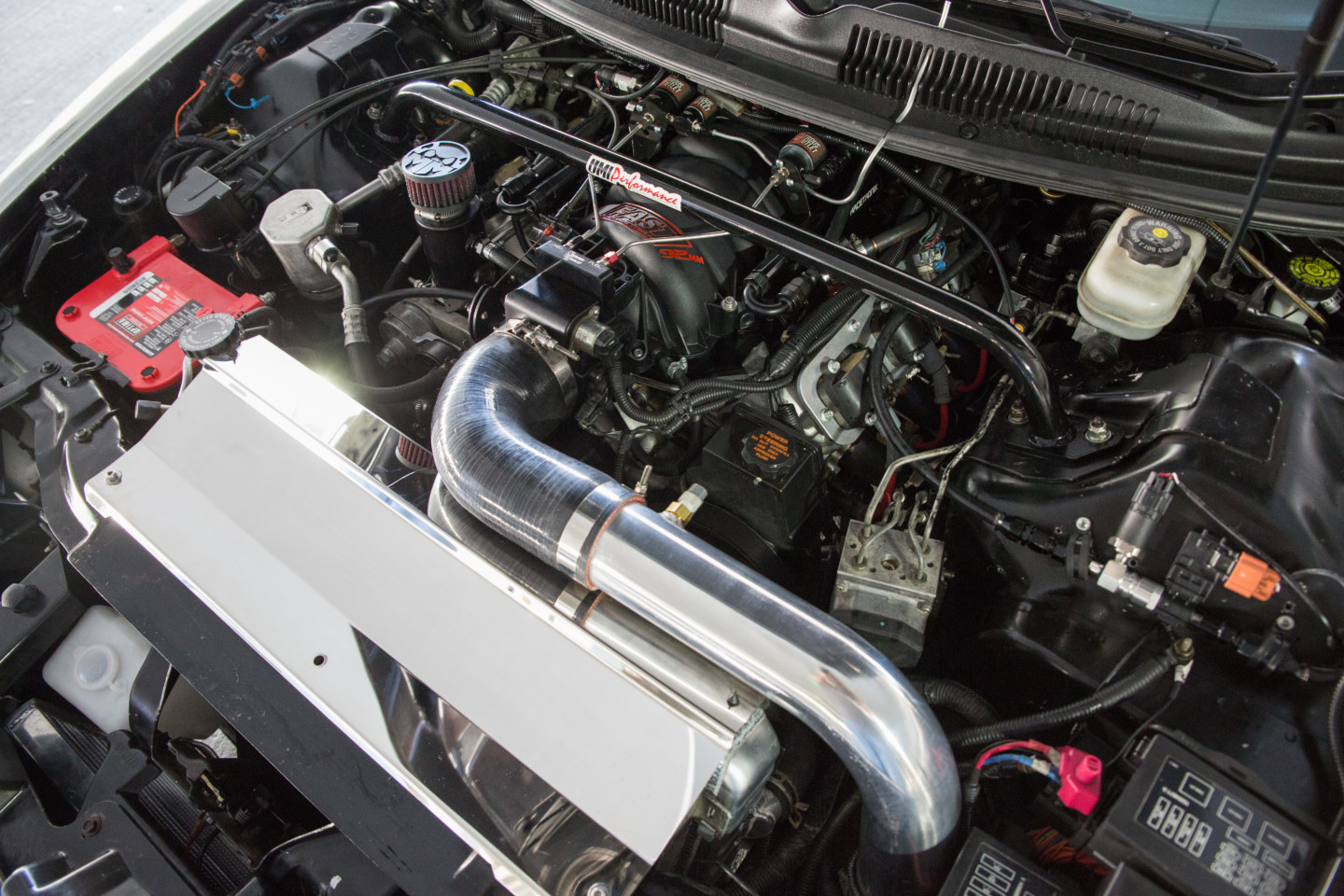

The Texas Speed and Performance engine alone would be a fantastic setup to taunt your local racers. Scott, however, wanted more and decided what better way to make more usable power than a supercharger and nitrous? Rocky Mountain Competitive Research supplied an intercooled Vortech V3 supercharger, the result of the built motor and supercharger added up to 740 horsepower.

A Button Away…

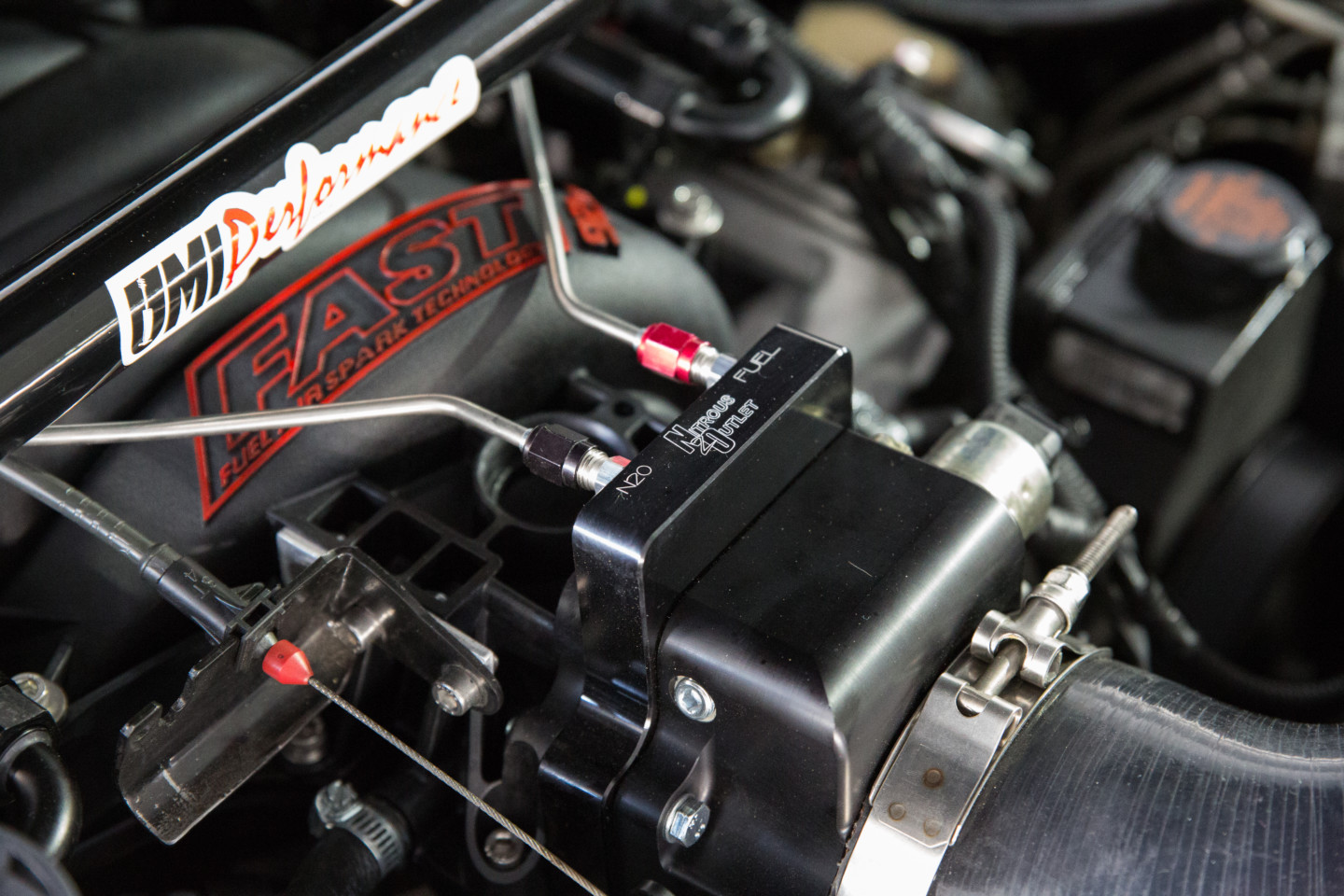

While not allowed in SCCA, local drag strips welcome the laughing gas. A 10-pound Nitrous Outlet bottle boldly protrudes between the two rear seats enabling easy access to open the nitrous valve. The system sprays through a 92mm FAST intake manifold. With nitrous, only the Chevrolet Camaro was propelled to a 10.6-second 1/4-mile time…not bad for a car that typically turns ten times before that distance.

In-Home Tuning

Most builds of this caliber with twin power adders have a well-known tuner or shop name attached, but Scott decided long before this that he wanted to learn how to tune his car via the stock PCM. Chad Starkey bought his first tuning cable, and Brian Turner of Dynotune assisted in the knowledge department. Scott disabled the mass-air setup and went straight to the manifold absolute pressure, or MAP sensor only. This catapulted Scott’s ability to make changes without revisiting the dyno. Scott has even begun to tune his friend’s cars, as well.

It’s very rewarding to make something run and operate correctly, whether I do it at work on people’s daily drivers, or after hours helping my friends get things working right.

Putting the Power Down

Although the stock 4L60E automatic four-speed transmission might lead to quicker 1/4-mile times, it was far from adequate for the newfound power. D&D Performance came to the rescue and built a T56 Magnum to handle the high-RPM shifts. The moment the MGW shifter is pushed into gear and the clutch is released, the T56 Magnum transfers power through a PST 3.5-inch aluminum driveshaft toward a Moser 9-inch rear end. The 31-spline Moser axles deliver the energy from the 9-inch through a Wavetrac spool to the rear wheels.

All the power in the world would prove pointless if you can’t put it to the ground, and American Racing Torque Thrust 2 wheels are mounted on each corner. The 17-inch wheels look the part and are 9.5-inches wide in the front and 11-inches in the rear. Finding the balance point between lateral and longitudinal grip sent Scott towards Nitto NT555 mounted on all four corners. The tires pull triple duty between autocross, drag racing, and spirited street driving. The front 275/40/17-inch tires tuck nicely in the wheel arch. On the rear, massive 315/35/17-inch rubber wraps around the wide wheels for some serious bit.

Handling was paramount for the build, and the GM two-link torque arm rear suspension, in addition to a low center of gravity, is a step in the right direction. But the subpar stamped steel OEM products just wouldn’t cut it on any road course or dragstrip. Removing some weight and improving handling required Scott to handpick from a selection of aftermarket components. UMI, Sam Strano Performance, Koni, and BMR all made the cut. After all, getting a 3600-pound chassis to handle is no small task!

Totally Tubular

Scott chose UMI to supply most of the tubular components for the F-body. A UMI K-member cradles the motor and ties the front suspension together, including upper and lower control arms. A UMI strut tower spans across the engine bay just above the intake, redistributing chassis flex and creating solid response during high-speed cornering. In the rear, a UMI adjustable torque arm reduces wheel hop, especially on hard launches. The adjustable Panhard bar prevents lateral movement when cornering and allows less side-to-side roll.

Koni struts and shocks have long since been a staple in the autocross community; their ability to provide superb handling at a cost-effective price means they are a no-brainer for most racers. Scott combined the Konis with a Sam Strano Performance custom springs and sway bars, increasing the factory 32mm and 19mm sway bars to a thick 35mm and 21mm, resulting in less body roll. A set of BMR subframe connectors completes the Chevrolet Camaro suspension package tying the front and rear of the Camaro together.

Keeping it Together

Scott’s Chevrolet Camaro appears to have it all together. One might think it was a one-time shopping spree leading to its current state, but that couldn’t be further from the truth. Scott has invested countless hours changing out items to improve them or replaced damaged components after high-stress failure while racing. After four engines, seven transmissions, and three nitrous kits, most would throw in the towel, but with Scott’s wife holding the title and the sentimental value, you know this Camaro will continue to terrorize everyone from a straight line and into the twisty corners.