While there’s never a shortage of killer LS-powered whips at LS Fest, this year’s Las Vegas event had a few builds that were worthy of more than just a double take, and among them was this L33-powered 1970 Chevrolet C10. Although swapping modern running gear into old school Chevy pickups isn’t exactly uncharted territory, there’s something about the juxtaposition of the truck’s rough and ready aesthetic and the build’s clean execution that really resonated with us.

“I actually got started with turbocharged Hondas,” explained Raul Gonzalez, a technical specialist for Audi from Chandler, Arizona.

Built for the Sport Front-Wheel Drive class, Gonzalez's Civic hatch is an import you don't want to mess with, boasting a personal best e.t. of 9.0 seconds at 175 mph. Gonzalez says his performance interests shifted a bit when his boss asked him to work on his '56 Chevy pickup. Restoring that truck would give the Gonzalez brothers an itch for a vintage hauler of their own.

“It eventually progressed into thousand-horsepower Civics built for drag racing, one of which I still have. One day my boss came to me and said, ‘I like the stuff that you guys do – can you work on my ’56 Chevy truck?’ He sent it over to us and we did everything from bumper to bumper. It was a really fun project, and it gave us the bug for building an old truck for ourselves to use as a shop truck and for towing the race car.”

Aside from exhaust cutouts in the front fenders and other small tweaks, the bodywork of the C10 is ostensibly unchanged from the state it was in when Gonzalez acquired the truck. It gives the C10 a mean, functional look that we totally dig.

Gonzalez says that getting the project off the ground was just a matter of connecting with folks who had established a proven formula. “My go-to guy for tuning was already into the LS swaps when I got the idea to build a truck, so I just started following their projects – they were doing stuff like LS-swapped Fairmonts and I saw how fast they were going with just stock motors with turbos and I was like, ‘man, this is cool!'” Gonzalez remembered. “So I slowly started piecing everything together, mainly buying parts from that tuning shop as they parted out race cars. They basically gave me the recipe for what works on the LS motors, and we just went from there.”

The Path To A Bitchin’ C10

While Gonzalez had the benefit of insight from experienced builders, the project wasn’t without its fair share of speed bumps along the way. “I started with another truck – a ’71 GMC Stepside,” he said. “It already had an LS swap when I got it, but once I started really digging into it, I realized what a hack job had been done with it. I ended up getting rid of that one so I could start over, and I came across this ’70 C10 that was unmolested and looked pretty cool.”

Gonzalez said his first attempt was something of a false start with this GMC Stepside. The truck had already been swapped to a modern powerplant, so Gonzalez expected a lot of the time-consuming tasks involved to be behind him. But closer inspection revealed some dodgy work that didn’t sit well with Gonzalez, so he ditched the Stepside and started the project over.

Of course, getting this modern powerplant into a half-century-old chassis isn’t just a matter of pulling out the old motor and dropping in the new one, but the awesome aftermarket support that exists for the LS platform makes it a lot less of a headache. “We used Classic Performance Products adjustable mounts so we could move the engine back as far as we could for better weight transfer, and we made our own cross member for the transmission,” Gonzalez told us. “We wanted to move the engine back as far as we could without notching the firewall.”

As you might expect, the C10 is a nose-heavy truck, so Gonzalez did what he could to move the L33 as far back as he could without significantly altering the chassis by using Classic Performance Products adjustable mounts.

Gonzalez decided to leave the body and paint as-delivered to retain the C10’s mean look, but the hardware underneath was fair game. “We don’t really like to buy off-the-shelf parts and throw them in – we like to do custom work where we can,” Gonzalez told us. “We try to make things unique, but we also want it to be easy to work on and clean, so we decided early on that we’d make parts ourselves when needed.”

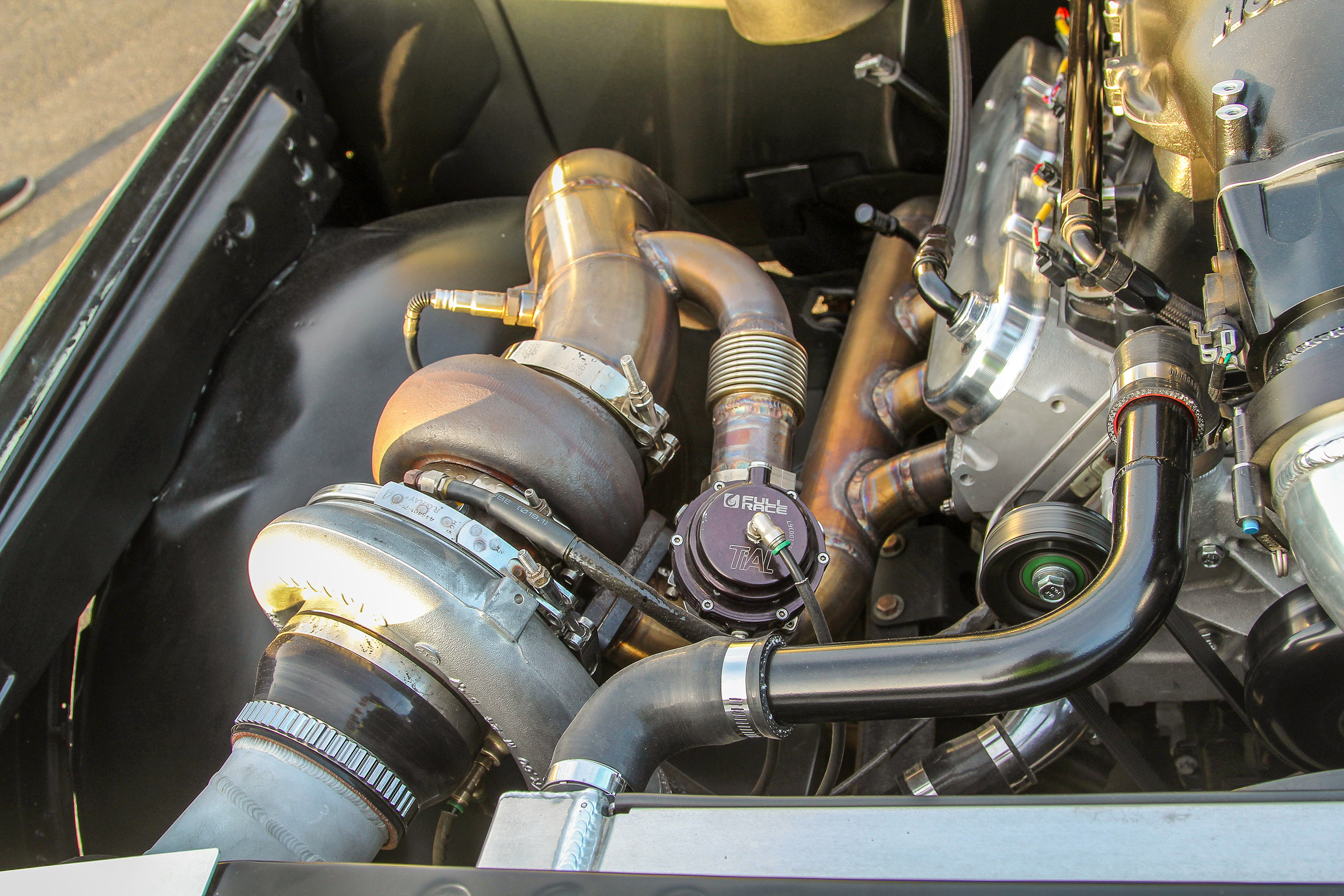

That fabrication work is most evident in the engine bay, where Gonzalez and his brother Juan put together an array of custom parts for the turbo system including the exhaust manifolds, a 2.5-inch crossover pipe, a 4-inch combination downpipe and dump tube, and the charge piping.

The 5.3-liter L33 was sourced from a race car that Gonzalez’s tuning shop was parting out. “In that car, it was making close to 1,000 horsepower,” he said. “But it was pretty beat up by the time we got it, so we decided to rebuild it.”

While the 5.3-liter L33 motor was a former race engine that Gonzalez scored from a local tuning shop, much of the turbo setup was actually snagged from his Civic drag car.

We don’t really like to buy off-the-shelf parts and throw them in – we like to do custom work where we can. We try to make things unique but we also want it to be easy to work on and clean, so we decided early on that we’d make parts ourselves when needed.

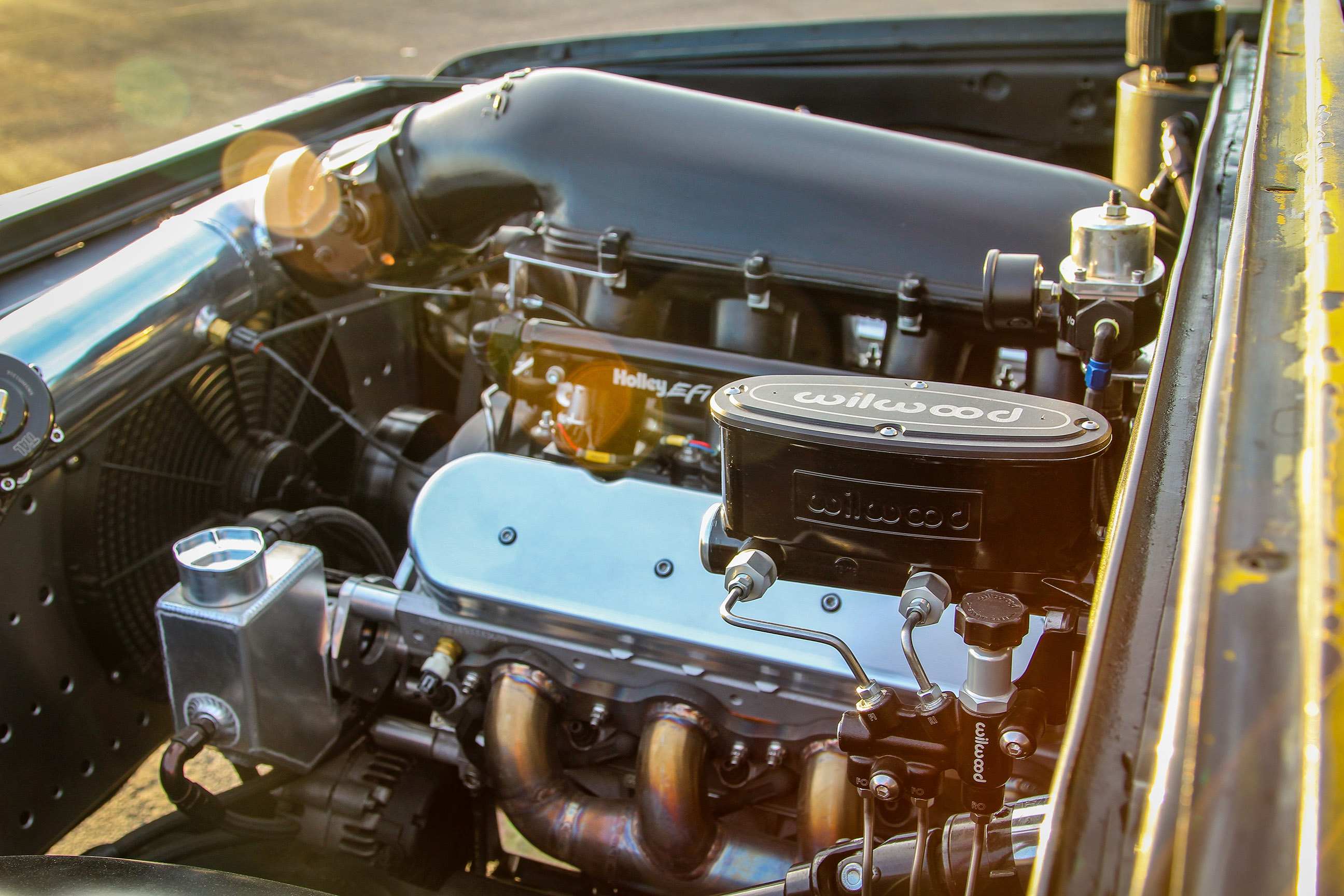

King Racing bearings and Mahle piston rings help fortify the bottom end while a Brian Tooley Racing Stage 1 turbo camshaft is paired up with a Holley EFI Hi-Ram intake manifold, a Boostflow 92mm billet throttle body, and factory cylinder heads that are bolstered by Brian Tooley Racing spring and retainers and pushrods.

The turbo setup consists of a Garrett GTX4502R ball bearing turbo with a 1.28 AR exhaust housing along with a Full-Race Tial 44mm MVR wastegate and a Full-Race Tial Q 50mm blow-off valve. “At 14 psi on pump gas it makes 538 rear-wheel horsepower and 561 lb-ft,” said Gonzalez. “On ethanol, it makes 648hp and 663 lb-ft of torque. Really the truck was just supposed to be a shop truck and for towing, nothing crazy. But once we got it going, we realized it was a lot wilder than we had expected.”

Not happy with the look of the stock ’70 C10 dash, Gonzalez bought a ’64 C10, cut the dash out of that truck, and re-shaped it to make it fit in the 1970 C10. A Holley EFI 7-inch digital dash serves as the truck’s gauge cluster.

A significant portion of the forced induction hardware was sourced from Gonzalez’s own garage. “A lot of the parts on the truck came off of my Civic race car,” he explained. “That turbo was on the Civic, along with the wastegate, the blow-off valve, and the Injector Dynamics 1,300cc injectors. All that stuff got pulled off of the race car mainly because it was just sitting in the shop.”

The power is routed through a 4L80E automatic transmission that was pulled from a 2004 Silverado 2500 and rebuilt with strengthened internals. The grunt is dispatched to the rear wheels through an Eaton Detroit Truetrac differential with 3.73 gears.

Gonzalez admitted that the chassis setup is a work in progress. “It’s supposed to be a street truck, so we didn’t go too crazy on the suspension, and to be honest it’s kind of sketchy on the street at times,” he said. “We put on dual adjustable Viking shocks, CCP’s drop spindles, front 2-inch drop springs, and sway bars, along with Moog ball joints, tie rods, and links. We also put a 70-pound ballast in the back, which helped a little bit, but the setup’s not quite there yet.”

All the exterior lights on the truck have been upgraded to LEDs that are installed in the original housings. A 16-gallon JAZ fuel cell with custom mounts keeps the L33 properly fed.

Stopping power is provided by a Wilwood dual-piston caliper kit up front and Wilwood’s DynaPro low profile rear brake kit in the rear, and the truck rolls on Weld Racing RT-S S71 wheels measuring 18×9.5 inches up front and 15×10.275 inches out back. Mickey Thompson Sportsman S/R rubber helps put the power to the ground while Nitto NT555 summer tires keep the front end of the truck pointed where it’s supposed to be.

“We started on this project at the end of 2016, and we had it running and on the dyno by this time last year in order to get it ready for the 2017 LS Fest,” he said. “So from start to finish, it took about six months, just me and my brother Juan doing pretty much all of it. We loved working on the project, so it went by pretty quick.”

Gonzalez said that hammering out some of the details required a little more work than he’d anticipated, but finding the hours necessary to put the project together proved to be the biggest obstacle they encountered along the way.

“We work long hours at our day jobs, so most of the work had to be done on the weekends,” Gonzalez said. “But it was the interior was a bit of a challenge actually. The original dash had a dash pad, and we didn’t like it, so we actually bought another truck – a 1964 C10. Those trucks have a flat dash without the pad used in the later models. We had to cut it out, shorten it, shape it, and make it removable. It took us about two solid weeks to get that done.”

We started on this truck at the end of 2016, and we had it running and on the dyno by this time last year in order to get it ready for the 2017 LS Fest. So from start to finish, it took about six months with me and my brother Juan doing pretty much all of it. We loved working on the project, so it went by pretty quick.

The Road Ahead

Though it was always intended to be a street truck, it may find its way into some racing before too long. “I’ve wanted to take it,” Gonzalez told us. “I need to get the suspension sorted out first though. I really need to do a four-link setup and actually work out the kinks. It’s not there yet, but we’re also not in any rush at this point, especially since I already have a race car to play with.”

Looking into the future, Gonzalez said that getting the truck to put the power down is the next major phase of the project. “We’re going to put some real work into the suspension and see if we can get it to hook, and if it doesn’t, I’m probably going add a traction control system to the truck,” he said.

Gonzalez says that at this point, power isn’t the issue – it’s getting the truck to hook up that’s still a bit tricky.

While the mechanicals are due for some tweaking, the aesthetic is still up in the air. “I haven’t decided on the body,” he said. “A lot of people really dig the paint the way it is now, but I feel like when I go to typical car shows here in Arizona people just want to see shiny paint, big wheels, and dropped suspension. It just doesn’t get much attention, so I’m not sure yet.”

Of course, we’d argue that there’s plenty of builds out there with nice paint and eye-catching bling, but the character of this C10 is truly unique. Regardless of what happens with the truck’s overall look, Gonzalez is happy to just spend time behind the wheel. “We’ve put 2,000 miles on it since we finished it – it’s been solid, no issues.”