If you’re like us, most of you know what it’s like to buy a car with the intention of adding a bolt-on or two. As you try to suppress those inner voices by limiting the modifications, one change leads to another. Before you know it, the car is completely stripped down, with the majority of factory parts stored in boxes. Travis Ball, the owner of Ball Metal Fabrication (BMF), knows this story all too well.

Travis has always been into cars. As a kid, his father would show him pictures of the different vehicles he owned in the ’70s. Travis’s first ride was a ’69 Chevrolet C10 and then a ’62 Chevy II that he drove in high school. In 2002 Travis’ boss, Kenny Davis of Kenny Davis Hot Rods, bet him that his Nova would never run faster than a 12.50 in the 1/4-mile. This is all it took for him to get pulled into the chronic illness we call drag racing. He was successful in winning the $100 bet as the Chevy II went a 12.32. Travis worked for Kenny for 15 years, helping build some of the most stellar hotrods that have graced the major magazine pages. But like most up and coming stars, it was time for Travis to do his own thing, so he started Ball Metal Fabrication in 2012.

Travis has struggled over the years to finish some of his own projects because his customers come first. He is one of the most talented welders and fabricators that we have met and has built some amazing vehicles for others. So, if you want a simple project because you don’t have time to build your dream car, what do you do?

Travis decided he wanted a car that wouldn’t require rust repair or time-consuming paint and bodywork. The vehicle needed to have potential with a ton of aftermarket support. Ultimately, the car of choice was a 2012 C6 Grand Sport Corvette, which was located in Dallas, Texas.

The day after I brought it home, I tore it apart for a few mods. For some reason, my wife was not impressed. – Travis Ball

The Inferno Orange C6 was in decent shape, with only 49,000 miles on the clock. When Travis got the Corvette back to his home town of Fayetteville, Arkansas, he immediately went to work. Travis said, “The day after I brought it home, I tore it apart for a few mods. For some reason, my wife was not impressed.” After two years of work, and in true Travis Ball fashion, we got way more than we expected from this “bolt-together” project. But, it’s Travis, and we knew better than to expect the mundane.

The first order of business was to build an engine that would hold together under some massive boost. For this task, a call was made to Gwatney Performance in Arkansas. The guys decided on a Chevrolet Performance LSX block used in conjunction with a Manley Pro Series crankshaft and rods that connect to a set of Diamond ceramic-coated pistons with a modest 10.7:1 compression ratio. The new combination bumped up the engine size of the C6 from 378 to 396 cubic-inches. COMP Cams supplied the boost-friendly camshaft that measures .623/596 lift and 239/254 duration at .050 with a 111-degree centerline.

With the cam in place, the short block was topped off with a set of Trick Flow 245 heads that were CNC ported by Total Engine Airflow and covered with Comp billet valve covers. Travis decided on a Brian Tooley Racing (BTR) Equalizer intake for air delivery, but not before some serious work was done. The brand new manifold was placed on the mill removing the logos and then smoothed the casting.

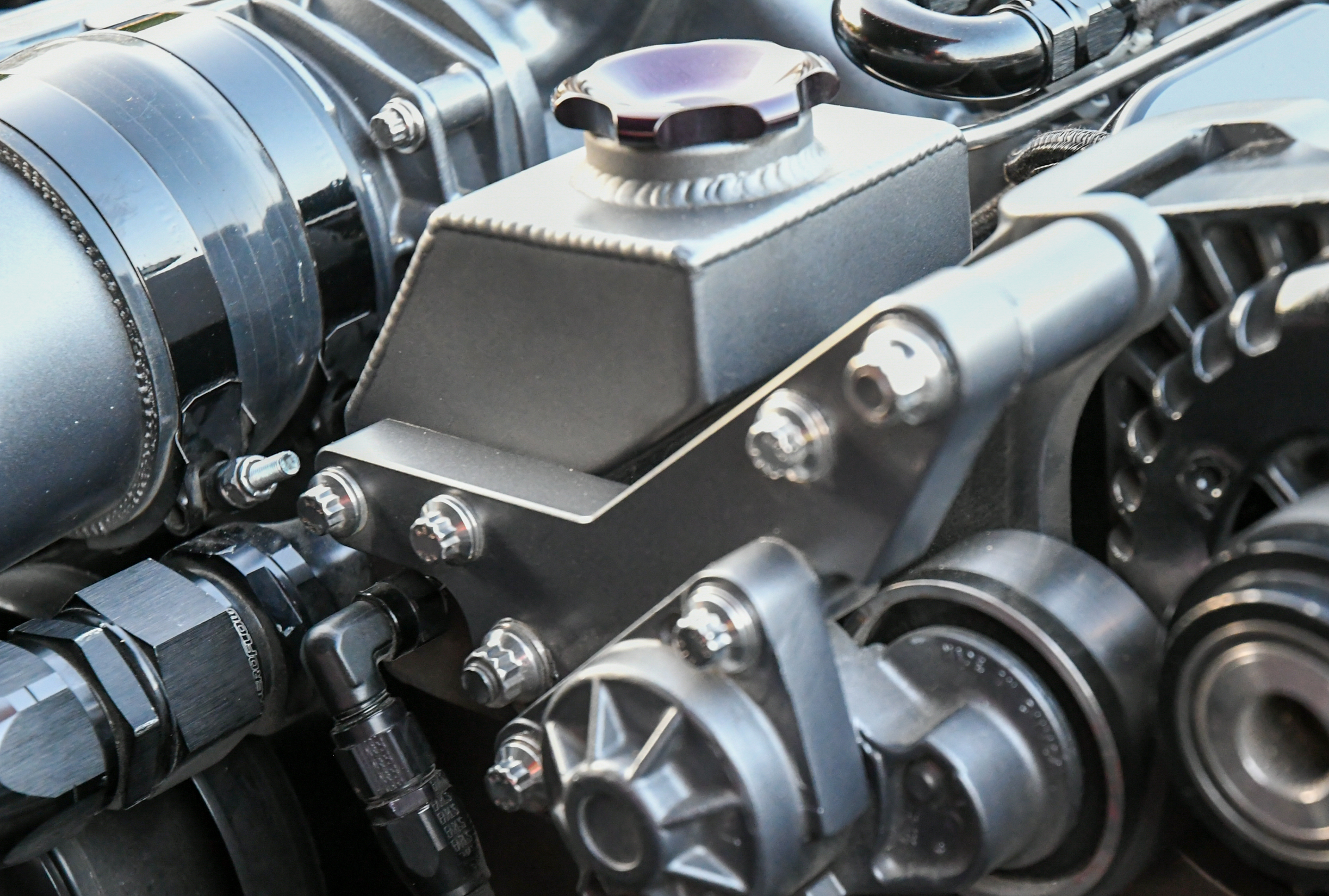

All the engine needed now was a power adder. For that, Travis used a ProCharger F1X, knowing it would easily supply the power levels he was looking for at the rear tires. The pulley selection for this setup is all business, with an 8.0-inch lower and a 4.250-inch upper, which has been good for spinning the supercharger to the tune of 36-pounds of boost. The ProCharger was paired with a No Corners Cut (NCC) Fab 1,500 horsepower, 3.5-inch intercooler, ProCharger Race Blow Off Valve, and 4-inch custom piping that leads to the throttle body. A set of Kooks headers and a 3-inch exhaust system were used with boost activated cutouts to rid the 396 of spent gases.

With the engine, ProCharger, and exhaust wrapped up; it was time to address the fueling needs for the Corvette. A Fore Innovations triple-pump system was installed in the factory tank. The unit has one 475 lph pump and two 525 units as well that feed the Bosch 210 injectors with the help of a Fore fuel pressure regulator. A ProEFI 128 ECU was used to control the fuel injection and engine functions.

Travis then addressed the Corvette’s cooling system, and since he had modified just about everything else in the car, why not? An NCC Fab custom radiator was fitted under the hood. Instead of setting it horizontally, he decided to mount it vertically. This design required more custom fabrication with aluminum ducting to cool the car. With the addition of a Meziere electric water pump, the car cruises effortlessly no matter how hot the Arkansas days may get. Travis also fabricated custom plumbing, coolant expansion tank, and catch can.

With the front half of the C6 complete, it was time to fix the next weak link: the drivetrain. Travis had every intention of this monster being a street car and stuck with the 6L80E for that reason. The transmission was removed and sent to Asylum Motorsports for a rebuild. A PTC triple-disc converter with a 4000 rpm stall speed was bolted to an RPM Transmission flexplate to tie the engine to the newly-built transmission. To keep the 6l80e temperatures at bay, Travis fabricated sheet metal ducts in the fog light openings that route the airflow through two Derale Performance coolers. The rear end is still stock at the moment with a set of 2.73 gears. The suspension on the C6 was fitted with LG Motorsports coilovers on the front and the rear to give it the proper stance.

I love the fact that this C6 is just as much of a street car today as it was when it was stock. The car drives effortlessly and never gets over 190-degrees, even with 1,300 horsepower on 100-degree day. -Travis Ball

Wheels can make or break a build, and Travis knows this better than anyone. For the rollers on the Corvette, a set of 18-inch Weld S77 fronts and 15×10-inch rears were selected. But instead of just bolting them on, he went the extra mile, of course. The Welds were smoothed, and then powder-coated EVO Grey to match everything under the hood. Base model rear brakes were used with LG Motorsports spindles to fit the 15×10-inch wheels on the rear. Toyo 265/35/R18’s tires keep the car pointed in the right direction, while the Mickey Thompson 275/65/15 drag radials keep the C6 hooked up.

As if there aren’t enough details with this car, here are a few that might go unnoticed to the standard automotive enthusiast.

ARP bolts are used everywhere on this C6. You can find them on the engine, intake manifold, exhaust, engine bay, ducting, and even on parts and pieces you can’t see. A C7 Carbon ZR1 ground effects kit and spoiler were smoothed, and painted Carbon Flash along with the stock rear diffuser. Anything and everything on the Corvette that could be, painted, coated, or polished, was. The DeWitts Paint & Body took care of painting the Corvette, giving it a perfect fit and finish.

After a two-year building process, the car was finally finished and ready to hit the dyno rollers. Justin Covington of Asylum Motorsports was called on to handle the tuning duties on the ProCharged LSX 396. Armed with 36-pounds of boost, the mill cranked out an impressive 1,289 horsepower and 989 lb-ft of torque, even though it was traction limited on the pull.

Travis has yet to get any 1/4-mile times with the Corvette. Hopefully, we will get some before the C6 sells. Yes, you read that right. This labor of love is for sale to the tune of $59,000. When asked about his favorite thing about this build, Travis said, “I love the fact that this C6 is just as much of a street car today as it was when it was stock. The car drives effortlessly and never gets over 190-degrees, even with 1,300 horsepower on 100-degree day.”

Like many projects, what started as a simple bolt-on project took two-years and a lot of blood, sweat, and beers to finish. And while we have featured some clean Corvettes in our time, this C6 Grand Sport is the most meticulously-built street car that we’ve ever seen. If you’re lucky enough to see it in person, you will know what we mean when we say it’s one of one.