“Third time’s a charm,” they say. And good things come in threes, too. But in the case of Terry Converse’s Corvette compulsion, those sayings don’t apply to a trio of Corvettes, but just one that has been “built” three times, each time taking about three years or so. How did he begin his trifecta of Corvette upgrades, ratcheting up the performance at each stage?

“Third time’s a charm,” they say. And good things come in threes, too. But in the case of Terry Converse’s Corvette compulsion, those sayings don’t apply to a trio of Corvettes, but just one that has been “built” three times, each time taking about three years or so. How did he begin his trifecta of Corvette upgrades, ratcheting up the performance at each stage?

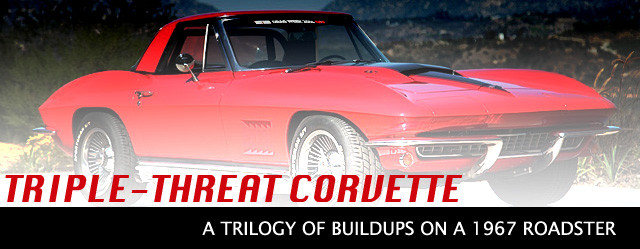

“I bought this 1967 Corvette big-block roadster in 1979,” he relates. “After 36 years, I still love this Corvette and now it is more powerful and more drivable than ever.”

What sparked a passion spanning more than three decades? It dates back to the 1950s. “My oldest brother bought a 1959 270 horsepower Corvette brand new,” Terry recalls. “He was a Navy pilot and was killed in a plane crash one year after buying the ‘59. That car was given to my older brother, but I caught ‘Corvette fever then. My first new Corvette was a 375 horsepower 1965 fuel-injected roadster.”

After that, his next new Corvette was as a 1979 L82 four-speed car that he had to buy out of state to get the L82 engine. But he still held a torch for C2 roadster Corvettes, since his first was a ‘65 model. He also has a preference for a particular type of engine.

“I like big blocks, so when I purchased the 1967 in 1979, it was an original big-block car with a 390 horsepower 427 four-speed,” Terry explains.

But the first of his triplet of buildups started out a bit rocky, as it needed much bodywork to repair front-end damage, and also removing the flared fenders. New leather seats and additional interior refreshing were also required over a three-year period.

Once those items were done, the car was painted Porsche India Red. The engine was a 468 ci big-block with a forged crank, rods, pistons and large rectangular-port Chevy aluminum heads, massaged to the max.

“This engine had a Holley 850 double pumper and a Doug Nash five-speed trans,” he adds. “This trans was okay, as it had a 3.27 first-gear ratio and fifth was 1.00,” says. Terry only used the first four gears drag racing, so he could run a 3.08 rearend, and it was like having a 4.11 in the first four gears. With Hooker IMSA style two-inch primary headers, and four-inch collectors, the car could run 11.90s on the strip with street slicks.

The next build took place from 1998 to 2000, not quite three years. This version featured a 540 ci big-block Merlin block, Dart Pro heads, 704 lift solid-roller cam, Eagle forged crank and rods, and forged pistons with a compression ratio of 11:1. Plus it had the added benefit of an intriguing innovation for the era.

The next build took place from 1998 to 2000, not quite three years. This version featured a 540 ci big-block Merlin block, Dart Pro heads, 704 lift solid-roller cam, Eagle forged crank and rods, and forged pistons with a compression ratio of 11:1. Plus it had the added benefit of an intriguing innovation for the era.

“I was a bit ahead of my time and installed an Electromotive direct-port fuel injection,” Terry noted. “This is a four-coil setup with a crank trigger (no distributor).” While Electromotive used all GM sensors, it still required much knowledge to program the ECM (engine control module). “I learned much about the benefits of EFI way back then,” he says.

The trans for this beast was TH400 built by Mike’s Transmissions, with a Continental 3000 rpm stall converter and Hurst Autostick 3 Shifter. The rearend needed to be much stronger, so a Tom’s GM 12-bolt was fitted into the Corvette carrier with 3.73 gears.

In addition, Tom’s notched trailing arms were fitted, along with 1450 large half shafts and U-joints. Tom’s upper control arms provide for control in the event of a U-joint failure on the strip (now a NHRA requirement for this generation Corvette at current et’s). For additional safety, a five-point roll bar was added.

Wheels for the strip were (and still are) American Torque Thrust IIs with Mickey Thompson Sportsman front and ET Street on the rear. Street Wheels are North American 15 x 8-inch wide, original-style knock-off wheels, wrapped with 50-series Comp TA tires. Strip performance was 10.60s at 128 mph. Clearly Converse was now able to shave off several ticks on the strip.

Wheels for the strip were (and still are) American Torque Thrust IIs with Mickey Thompson Sportsman front and ET Street on the rear. Street Wheels are North American 15 x 8-inch wide, original-style knock-off wheels, wrapped with 50-series Comp TA tires. Strip performance was 10.60s at 128 mph. Clearly Converse was now able to shave off several ticks on the strip.

For build number three, done between 2013 to 2015, Converse decided to get even more contemporary. “I liked the potential of electronic fuel injection, especially with the current-generation GM ECMs. The LS motors offer great power per cube, with great drivability. So I decided to go modern and pulled the 540 ci big-block.”

Before replacing it, though, he noticed something else requiring attention. The paint was now 31 years old and needed to be redone. Octavio Miranda of Miranda Autobody in Fallbrook, California painted the ‘67 using PPG original Corvette Rally Red with the Tuxedo Black Stinger hood.

“When the paint was done I purchased a LS3 427 from Blueprint Engines,” Terry relates. This engine was bored slightly and uses a Scat forged stroker crank and rods, with forged Mahle pistons. Heads are GM L92 with factory LS3 manifold. The cam is from Comp Cams, 624 lift, 239-255 duration at .050, 114 LSA.

“I wanted to get back to a manual transmission (for fun) so initially I used a Tremec TKO 600 five-speed,” he points out. It had a McLeod dual disc clutch with hydraulic throw-out bearing. The rearend remained as done in build number two. Mike Saiki (Motivational.Net on Facebook) performed the installation with Terry helping all the way. They used a Vintage Air front-pulley setup with both air and power steering.

“I installed the under-dash evaporator and controls, and Mike connected all the A/C lines, as well as all required fuel and water lines,” Terry says. Headers were initially off-the-shelf units with 1 3/4-inch primaries, and three-inch collectors with round mufflers for street use. This exhaust fits under the original factory side exhaust covers.

Terry felt the setup was nice enough, but just did not have the performance that he expected or wanted. “I competed in Hot Rod Drag Week 2014 in Street Race Small Block Naturally Aspirated, with average times in the 11.50 range at about 120 mph,” he recalls. “I finished ninth out of 25 cars in this class.”

Terry is pretty open about this initial shortfall. “When I purchased the LS3 427 I did not know my LS history well enough,” he admits. “Even though my engine is 427 ci, the LS7 would have been a higher performance starting point with a larger bore and shorter stroke with superior heads, versus the L92 units. It took $2,500 to get the L92 heads to flow about the same as stock LS7 heads.”

This year he set out to get to the old big-block performance times. To accomplish this goal the transmission was changed to a Tremec T56 Magnum six-speed. “This trans shifts as fast as I can move the lever at any RPM,” he points out. “The TKO 600 as modified for installation in a C2 is just not going to shift quickly.” The T56 has a 2.97 first gear, only gears one to four are used for drag racing, with a nice double overdrive final at .5.

Next we ported the L92 heads (West Coast Racing Cylinder Heads) to the Stage 3 with larger exhaust valves and flow rates equal to LS7 heads. Larger 1 7/8-inch primary and 28-inch length headers were custom fabricated by Mike Saiki. New Magnaflow mufflers were used including 2.5-inch ID catalytic converters for the street, and shorter mufflers for the strip (or open headers where allowed).

Next we ported the L92 heads (West Coast Racing Cylinder Heads) to the Stage 3 with larger exhaust valves and flow rates equal to LS7 heads. Larger 1 7/8-inch primary and 28-inch length headers were custom fabricated by Mike Saiki. New Magnaflow mufflers were used including 2.5-inch ID catalytic converters for the street, and shorter mufflers for the strip (or open headers where allowed).

“I liked the Holley Hi-Ram two-piece manifold and thought it would work well with the ported heads and headers,” Terry notes. “The ‘67 Corvette does have a 427 hood with good clearance, but the Holley was too tall and the inlet needed to be aimed downward a bit to clear the hood.”

So, he had Fred Fadich of KDF Machine in Poway, California fabricate the upper piece and machined the two half-inch flanges down to 1/4-inch for the Holley and got it to fit under the original 427 hood. Cunningham Motorsports in Murrieta, California dyno-tuned the original LS setup and this one too. Ryne Cunningham managed to squeeze 530 rwhp out of this motor on a conservative Mustang Dyno.

The next step was to bolt on new Wilwood front disc brakes that saved about 25 pounds per corner, and reduced rolling resistance. This new motor setup needs to run at 6,000 to 7,100 rpm range. To gear the car down a bit, 15-inch Hoosier slicks measuring 26 inches tall x 10-inches wide are used. Prior runs were on 28-inch tall Mickey Thompsons. The shift light by Raptor Performance gives Terry the desired 5,000 rpm launch signal and alerts him to the 7,000 rpm shift points.

The next step was to bolt on new Wilwood front disc brakes that saved about 25 pounds per corner, and reduced rolling resistance. This new motor setup needs to run at 6,000 to 7,100 rpm range. To gear the car down a bit, 15-inch Hoosier slicks measuring 26 inches tall x 10-inches wide are used. Prior runs were on 28-inch tall Mickey Thompsons. The shift light by Raptor Performance gives Terry the desired 5,000 rpm launch signal and alerts him to the 7,000 rpm shift points.

Build number three is particularly satisfying, as it has both good performance and drivability. That wasn’t the case after Build number two with the 540 ci big-block with a TH400 trans. “The car was good for drag racing and not much more,” he admits.

There were other drawbacks that Terry had to overcome. The soft top could not be used with the Build number two rollbar, so it was either hard top or no top. There was no air conditioning, and this beast got only six to seven miles per gallon. There were a lot of exhaust fumes to breath, too, so “the car was not wife friendly.”

Build number three started by taking out the 540 big block and TH400. The new roll bar required cutting the body panel cover for the convertible top. This needed to be done prior to painting. Next came the paint, and finally the 1,001 things required to install a modern engine.

For example, the instrument cluster had a mechanical tachometer. There is no provision on any LS to mechanically drive the tach, so the in-dash tachometer had to be removed and upgraded to an electronic VDO tach with the original face. The battery gauge was converted to a voltmeter. All the paint work and Vintage Air installation needed to be done before installing the new LS engine.

Now, the performance is back to where the 540 was and with a manual transmission with great overdrive. Build number three has a new five-point roll bar that was designed to work with the soft top up or down, and of course the hard top.

“We can cruise with the top down and if it gets too hot we just put up the soft top and turn on the A/C,” he smiles. “The Vintage Air works great.”

What has motivated Terry to make all these modifications over the years? “Passion for this car and to have a ride that looks good, looks stock, runs great at the drags, and drives like a more modern Corvette.”