Reviva, a Minnesota-based engine remanufacturer, has over 70 years of catering to the industrial sector. However, the company is becoming better known by hot rod enthusiasts for being on the leading edge of LS engine swaps. How a long-standing remanufacturer of industrial equipment suddenly became one of the leaders in high-performance LS platforms has intrigued many auto enthusiasts.

Reviva is well known in the industry for taking monstrous diesel engines like this one and rebuilding them for commercial fleet use.

Celebrated as the largest diesel-engine remanufacturer in the U.S., Reviva first expanded into the restoration and hot rod market with LS engine offerings. Originally, this raised some eyebrows. These days, the company has firmly established itself in the LS market, helping to lead the next wave of LS engine swaps in street rods.

We set about to discover the catalyst for this move by the company. What we found in the heartland of Minnesota is truly the character of the restoration market.

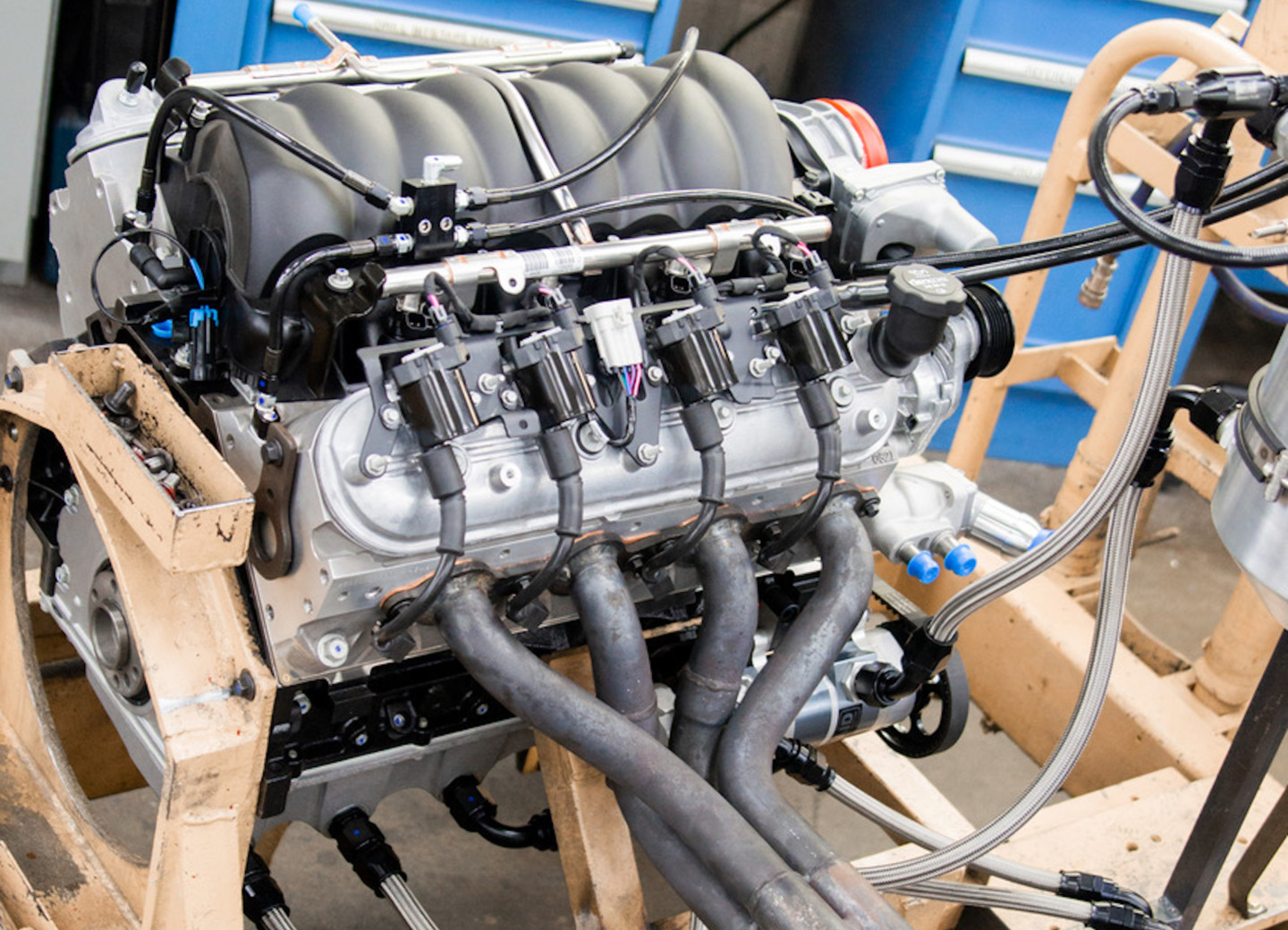

Shifting gears slightly, the company has added a line of GM LS-based high-performance gas engines in recent years.

Meet Josh Stahl

The current President (and majority owner) of Reviva is Josh Stahl. Josh is the typical automotive enthusiast. Growing up with wrenches in his hands, he spent five years as a Coxswain in the Coast Guard. His military career has been over for many years, but many of the lessons he learned in the service have carried over to the business world.

Photo of Josh Stahl and the famous LS-powered ‘Red Pig 2’ widebody Mercedes. (Photo from carsyeah.com.)

A Coxswain (pronounced “cox’s’n”) is an enlisted man who has physical control of an open boat. The type of boat that is normally small enough to be carried aboard another vessel. Responsible for the navigation and steering of a Naval vessel carries large responsibilities – similar to running a successful company. Josh still enjoys driving boats, cars, and motorcycles, or anything else with an engine. His other hobbies include racing in triathlons and endurance competitions.

How It Began

“My grandpa actually purchased the small company back in nineteen-sixty,” said Josh, “So it’s been in my family 60-years.” The shop was started during WWII to recondition parts because there was no new production happening at that time.” Presumably, due to the rationing of metals and other goods which was common for the era.

In the beginning, it was like a small, two-man shop. – Josh Stahl

“In the beginning, it was like a small, two-man shop,” Josh explained. “My Grandfather was a purchasing guy for Sears. Instead of moving to Chicago, he intended to be his own boss and bought this tiny little shop, and that is how we started.” From those meager beginnings, “he just kind of worked it and grew it.”

Reviva Timeline:

- 1944 – Founded as Dealers Mfg. in Minneapolis.

- 1960 – William Goodwin acquires Dealers Mfg. with a $75,000 SBA loan.

- 1975 – Goodwin’s son David takes over the company.

- 1995 – David Goodwin’s stepson Josh Stahl joins.

- 1996 – David Goodwin’s son Ben Goodwin joins.

- 1998 – Ford drops Dealers Mfg. as an authorized remanufacturer, but it remains a parts distributor.

- 2002 – The family changes the company name to Reviva to help it stand out as a brand, with the tagline, “Revitalize, Retrieve, Recover.”

- 2008 – Reviva acquires North Dakota-based Engine Rebuilders.

- 2009 – Josh Stahl named president of manufacturing.

- 2010 – Reviva seeks new sources of business after Ford cuts back during the economic downturn. Reviva launches FreightBuddy, a less-than-truckload (LTL) freight quotation, and scheduling business.

- 2015 – Reviva introduces new products and new product lines. They expand their national fleet business.

- 2016 – Reviva now solely focuses on manufacturing, divesting its distribution-related businesses.

Starting out as a business working for Ford Motor Company, the company has progressed since then. In the many decades of operation, it has circled back and now branched out in recent years. “My Grandpa was called a Ford authorized manufacturer when he was starting out. So, the company had a territory for Ford Motor Company where we would manufacture specific components for dealerships in our territory.”

He continued; “We’d buy the components from Ford, then manufacture the assembly to sell to Ford Dealers.” At that time, vehicles were not as complex and complicated as they are today. The “Authorized Manufacturers” handled almost every aspect and system of the vehicles.

“For example, we did starters, alternators, generators, clutches, engines, transmissions, window lift motors, you name it. We did all of that stuff,” Josh proudly exclaimed. “Then Ford changed their model.”

The Industry Goes Specialized

Reviva’s engine rebuilding plants are filled with commercial engines being received or getting shipped. The floor is covered with engines of all sizes, configurations, and types (gas and diesel).

As Ford started assigning roles to the authorized dealers, they became more of a distribution service than a manufacturing part of the business. “We just never gave it up,” said Josh of the manufacturing end of the company. “We stopped selling into the Ford distribution network because we had enough customers outside of Ford for our engines that we just continued on without Ford on the engine side.”

Branching Out

The company continued to operate with a large presence in the engine remanufacturing service for the next thirty years when the company branched out even further and renamed the engine division Reviva in the late ‘90s.

We kind of revitalize quickly and recover stuff and fix it up.

“We were into dealer’s manufacturing, dealer’s distribution, and dealer’s engine sales. We needed a little differentiation, so Reviva came about as kind of a revitalized recovery and that kind of thing,” he added. “And that’s what we do. We kind of revitalize quickly and recover stuff and fix it up.”

Currently, the company has over 220 employees under the Reviva banner. These employees work in 30 or 40 different departments within the team. According to Josh, he’s worked in most departments at one point or another.

Starting from a small two-man shop, the company now boasts of a workforce that is well over 220 people and growing.

The Path To Company President

After graduation from High School, Josh went into the service for five-years. Upon being honorably discharged, he returned home with the idea of becoming an environmental engineer. “I really enjoy the outside and I wanted to work outside, I just didn’t like the classes,” he said. “I didn’t like geology, I didn’t like science, but I did like economics.”

“My Dad said that he could give me a job driving a semi if I got my class A license and pay me more while I was going through college.” So that is what Josh did – he drove his way through college in a semi.

After college, Josh went back to the family company full-time. “I liked the automotive part of it,” he says. “I like the mechanics of it. I also really liked the part of having a product and being able to sell. You know, a specific something like a starter and alternator, or whatnot. I enjoyed that part of it and it just kind of snowballed from there.”

Knowing that he needed to gain experience in the other parts of the business, Josh’s father moved him into different departments for the experience. Knowing every facet of the company would eventually serve him well.

Personal Growth

After doing some of the maintenance, he was moved into the accounting department for a while. Then a term in the materials department. “I ran the shop floor for a few years after that.” His father had a plan. “I pretty much did about six or seven years of working in every department in the company. Then I did a spin-off called DM2 about 20 years ago.”

DM2 focused on specialty gas engines and diesel fuel systems. “We did tuner diesel stuff and specialty gas engines for specific applications. That’s when we first started dyno testing for drop-in gas engines for fleets. And that’s how I got into it.”

“As I got older and even more involved, I took on more responsiblities and we essentially completed a transition to the next generation. Now I’m the majority owner,” Josh said proudly. “We build diesel engines, anything from a half-liter up to 14 liters. For gas engines, we build pretty much the larger displacement stuff.”

A Peek Behind The Curtains

The company has three engine plants where they remanufacture gas and diesel engines ranging in size from .5L to 14L. Reviva also offers a line of high-performance LS engines for Hot Rodders and Restoration projects. The company also partners in a large machine shop that supports the defense and oil and gas industries.

While the company came from Ford Motor Company roots, Reviva has broadened out to GM gas engines in the last few years. “We were doing a lot of diesel work for a customer and they were starting to spec their fleet with GM gas engines. That’s how we got into GM gas engines.”

The company applies the same successful practices they have used in remanufacturing commercial diesel engines to the high-horsepower gas engines. Restoring bolt threads in engine bosses and other detailed work has been perfected over time.

When it came to servicing the street rod market, Josh made it clear this was a direction they had wanted to go for a long time. “I had wanted to get into this business because we build a really good, strong, commercial-grade engine. When I started talking to some of the car builders, when it came to electronic fuel injection and ECUs, it was difficult for many of them. Grasping the integration between the engine, the electronics, and the car.”

The problem created by modern electronics was one that could easily be solved by the team at Reviva. “We do this integration all the time with the different truck engines we build. It just made sense for us to come up with a platform that would work with these custom cars.”

Engine Choices

The team now offers three different options in their High-Performance gas engine line:

- 600 Horsepower 408cid (6.7L)

- 525 Horsepower 370cid (6.1L)

- 450 Horsepower 370 CID (6.1L)

The complete drop-in platform includes an Intake manifold, throttle body, fuel rail, injectors, water pump, spark plugs, ignition coils, thermostat and housing, vibration damper, sensors, and more.

For more information about Reviva, and their LS-based engine platforms for hot rods and street rods, visit them online at Reviva High-Performance. Make sure to stay tuned for upcoming tech articles on Reviva’s engine building operations.