In a small town in northern Michigan, there is a man making waves in drag racing, and more specifically, he’s got the LS community’s attention. You may know him from Instagram and YouTube, Kenny Dangler’s passion for fast cars runs deep. When he’s not trying to set records on the track, he spends his time building high-performance cars and trucks for customers at his shop, Northern Performance Cars in Gaylord, Michigan.

This article has been updated as of April 26, 2024 to reflect the current hydraulic roller camshaft record. The update can be found at the end of this article.

Kenny’s third-gen Camaro is one of the nicest we’ve come across. Careful attention has been paid to every detail of this car from front to rear.

Humble Beginnings

Kenny describes Northern Performance Cars as a small shop but told us it has given him the opportunities to do some cool stuff and to grow over the years. “I had a tough start, but it’s smooth sailing now,” Kenny said. He has always been a Camaro guy with a fondness for cars from 1982-1992. So it’s no surprise Kenny chose a third-gen Camaro as the basis for what is his biggest and most involved build to date.

Before this build, Kenny had put together some all-steel all-glass type cars that were plenty quick. Although he refers to his previous cars as bolt-together with minor fabrication, don’t be mistaken, his Fox Body Mustang ran 4.38 seconds in the eighth mile. “I’ve had several fast cars, but this is the first chassis car I’ve built,” Kenny said. “I’ve done some great builds in the past and have taken what I learned from the previous cars to build something better each time.” This latest project took him two years to complete, but technically, only six months to build. According to Kenny, parts delays held things up extensively. “I could have had the car completed last year, but it took a year to get some of the parts,” Kenny explained.

Kenny Has A “Built Not Bought” Mindset

With everything needed finally under the Northern Performance Cars’ roof, Kenny got to work with intensity. When it comes to race cars on this level, certain aspects of the build are typically outsourced to different experts that specialize in one area of the car. That is not the case here, as Kenny is very proud of the fact that he and his team are responsible for the entire build. “I built every single part on the car in-house other than the transmission, which I purchased from FTI,” Kenny said.

A jungle gym of chromoly tubing like this would scare a lot of DIY enthusiasts away from doing it themselves. Not Kenny, he built the whole chassis in his shop and painted it too.

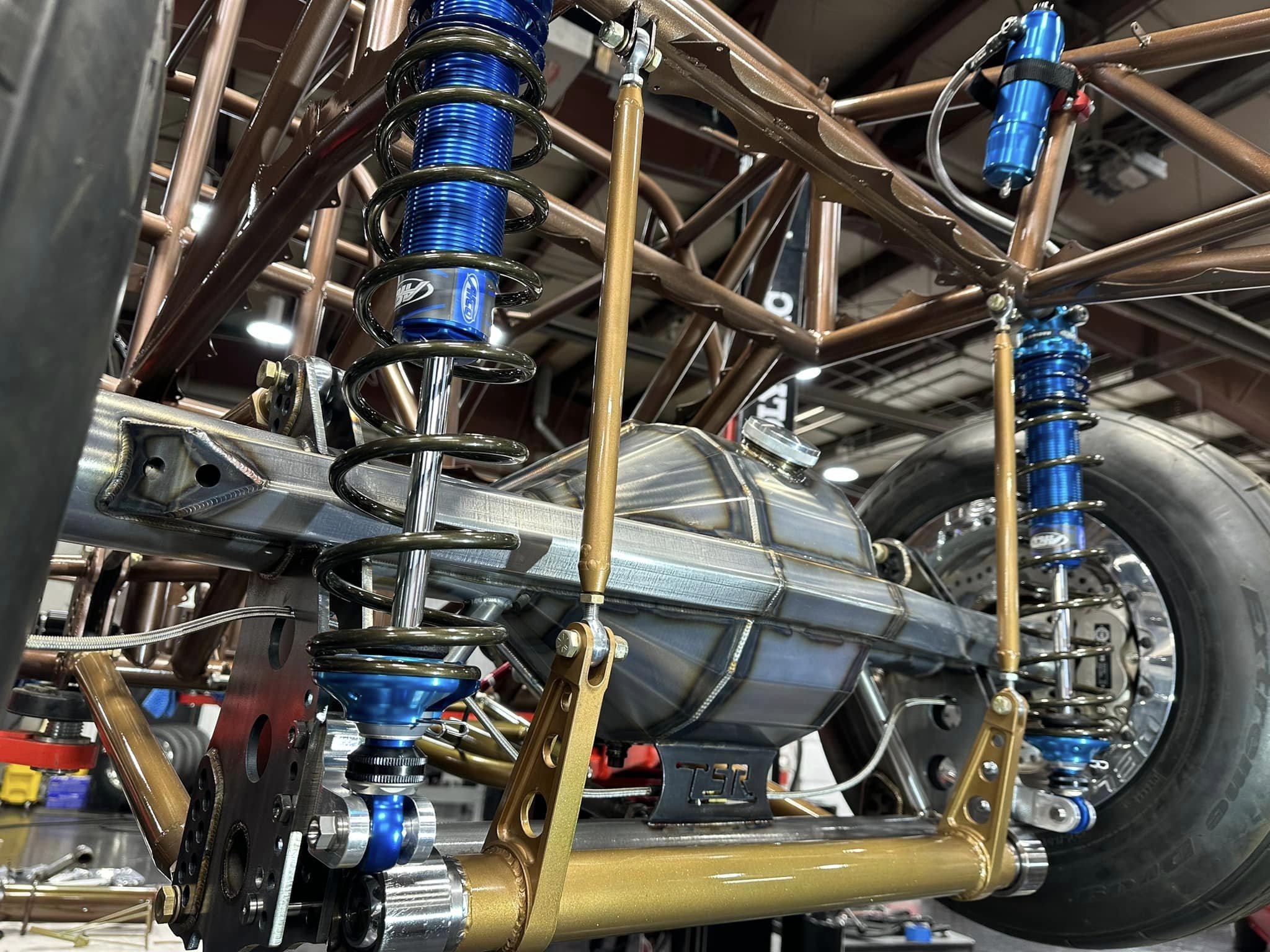

Starting with the chassis, Kenny bent and welded all of the chromoly tubing for necessary for SFI certification. He is also responsible for all of the paint and bodywork and mounting the body to the chassis. Using some spare chromoly tubing, Kenny fabricated his own tubular front end to mount the fenders, front bumper, and headlights. The front suspension consists of worked-over Afco coilovers with spindles by Dave Connelly at Competitive Suspension. The rear axle housing is a masterpiece from Tin Soldiers Racecars. The 9-inch housing is filled with Strange third member with a spool and 40-spline gun-drilled axles. Slowing the car down from low four-second eighth-mile passes are TBM brakes all around. Kenny’s third-gen rolls on 15×12-inch Weld V-Series beadlock rear wheels with 4 inches of backspacing. Traction comes from sticky 275/60/15 Mickey Thompson Pro Radial tires. The front wheels are 15-inch spindle mount Weld B-Series wrapped in 25×4.5-inch Mickey Thomspon ET Front tires.

In addition to building and fabricating as much as possible himself, Kenny wisely worked with top-tier companies like Tin Soldiers Race Cars, Afco, Weld, and Mickey Thompson to complete this beautiful build.

Building A Record-Setting Combination

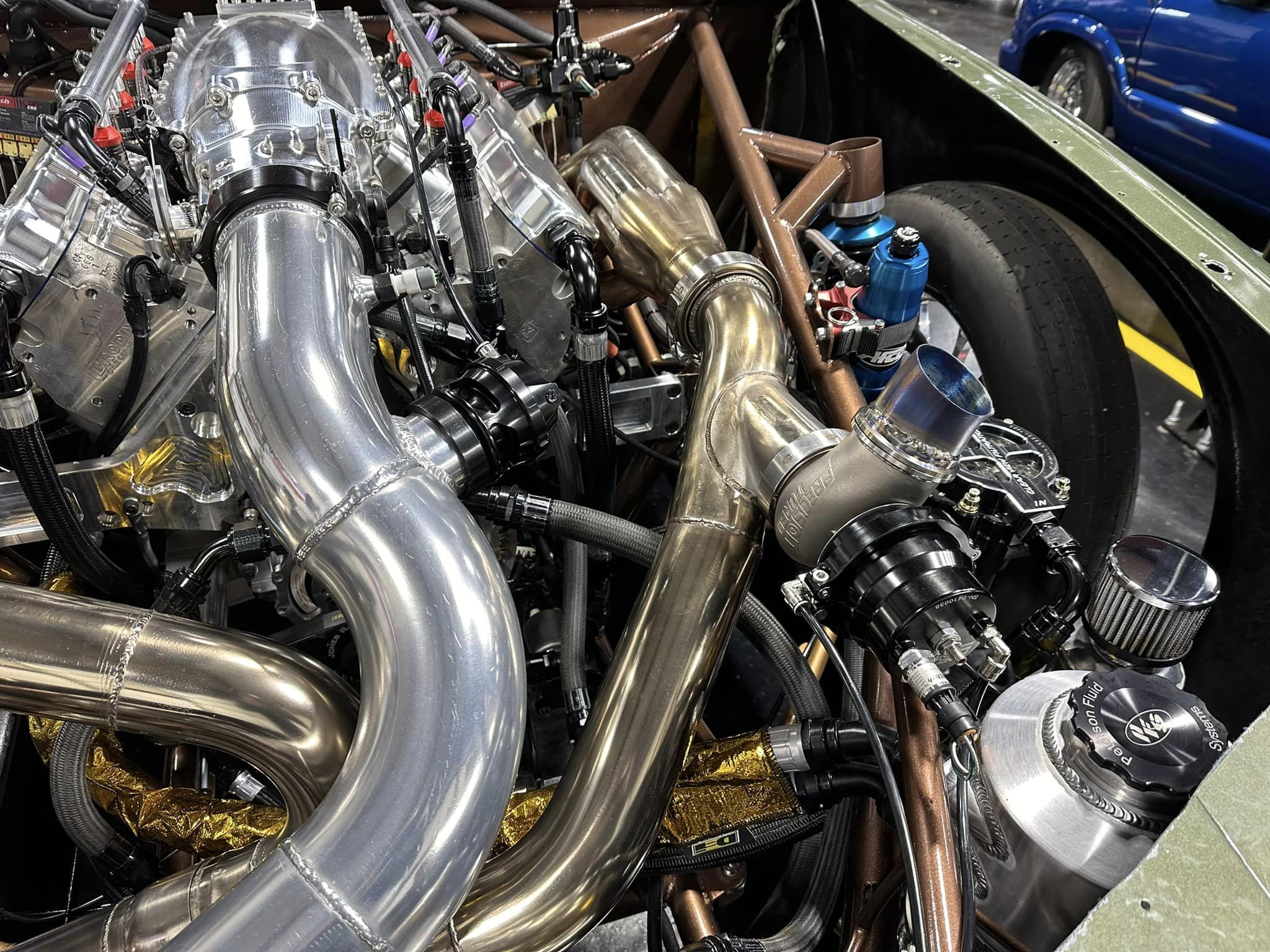

The engine powering Kenny’s third-gen Camaro is just as pretty to look at as the rest of the car. As with the rest of the car, Kenny built his 388 cubic-inch LS engine in-house. Starting with a dry deck billet block from Energy Manufacturing, he installed a 3.625-inch stroke center-counter-weighted Callies Magnum crankshaft along with R&R 6.620-inch aluminum connecting rods. The pistons are off-the-shelf Wiseco units from BTR for the 4.125-inch bore and feature upgraded .250-inch Trend wrist pins.

Up top, the Brodix BR1 cathedral port cylinder heads are assembled with titanium intake valves, 1209x PAC springs, and BTR rocker arms. Athena head gaskets help keep things sealed up. Kenny is tight-lipped on the specs of the custom camshaft from Nick Evdos at BTR, but he did share that it is a true .629-inch-lift cam. The rest of the valvetrain consists of Johnson Lifters which are a .903-inch bodied hydraulic link bar lifter and 5/16-inch Trend Series 5 pushrods. “We are using a legit hydraulic combination and not some tricked-up roller that’s set up like a solid,” Kenny explained with a laugh.

The 388 cubic-inch LS engine looks as nice as the rest of the car. Making over 2,000 crank horsepower is a plus too.

Providing boost is a single turbocharger system that Kenny fabricated in-house. “I designed the placement and scaling of the turbo kit to both come apart easily and make sense,” Kenny said. The turbo is a 110mm GT55 from Forced Inductions. Additionally, twin 66mm waste gates from Precision Turbo and a Turbosmart blow-off valve complete the system.

The Forced Inductions 110mm turbo is responsible for pushing 40-plus pounds of boost through the engine.

Sending power to the rear is an FTI Powerglide transmission with a 1.58:1 low gear, a 264mm bolt-together converter specced by Pete Nichols at Circle D, and a carbon fiber driveshaft from Precision Shaft Technologies. Feeding enough fuel to this engine for over 2,000 crank horsepower takes a big fuel system. Kenny uses a 17.5 gpm Waterman cam-driven fuel pump to supply VP Racing Fuels M1 methanol to Fueltech 720 lb/hr injectors. Controlling everything is a Fueltech FT600 ECU with Fueltech’s generic V8 wire harness. The car was wired entirely by Kenny and his brother, Tim Webster.

The interior of Kenny’s Camaro is all race car. As with the rest of the build, Kenny is responsible for the carbon fiber work, paint, and even the wiring with help from his brother.

Fast Out Of The Gate

Completing a build of this caliber in six months is a monumental accomplishment. Before the dust could settle, Kenny strapped the Camaro to his Dynojet chassis dyno to perform the tuning. With the Forced Inductions turbo making 42 pounds of boost, the little LS engine produced 1,822 wheel horsepower. The following weekend, Kenny took the car to Bradenton Motorsports Park to get the Camaro sorted on the track. “On only the second pass ever in the car, we got down the track very impressively,” Kenny said. After making minor changes to the suspension and engine tune, he was able to reset the hydraulic roller eighth-mile record with a 4.125-second pass at 181.94 mph. Needless to say, Kenny was absolutely pleased with how his third-gen build turned out. The weekend following his resetting of the hydraulic roller record, he took the car to US131 Dragway and lowered the record again by making a 4.069-second pass at 181.1 mph with an impressive 1.03-second 60-foot time.

“The car was built to work with a few wonderful companies. We wanted to showcase what we, and they, could do pushing the envelope of the hydraulic roller stuff,” Kenny said. To achieve this level of performance race cars have to be built to handle a lot of power and be able to transfer it to the track. Weight plays a large role in the equation and Kenny explained that he built his Camaro as weight-conscious as he could. “It weighs in at 2,520 pounds ready to race with five gallons of fuel and myself in the driver’s seat.”

Debuting the car at a Street Car Takeover event, Kenny made his first passes in the car and managed to take home a win an reset the hydraulic roller eighth-mile record.

Kenny Has Unfinished Business

As his first real race car and first eighth-mile car, Kenny plans to put his third-gen into the three-second range. He just doesn’t know how far it’ll go. “I think we have a great chance at mid to high 3.9s.” As with most achievements in the LS community, there are the usual comments about micro-records but one person, in particular, has announced that he’s coming to challenge Kenny for the hydraulic roller record. YouTuber Jon Doc previously had the record and is building another engine to try and recapture it. This should make for an interesting back-and-forth battle this year, and we’re excited to see how deep into the three-second zone these guys will end up.

Update: Kenny has wasted no time putting his third-gen Camaro into the 3-second zone in the eighth-mile. It wasn’t long ago that the idea of a 3-second hydraulic roller camshaft combination was just a dream. Today, not only is Kenny the first person to make a 3-second pass with a hydraulic roller camshaft in an LS engine, but he’s doing it with only 388 cubic inches. Just as impressive as his 3.98- and 3.97-second passes are his back-to-back 1.0-second 60-foot times. Not one to rest, Kenny is considering a turbocharger size change to continue his journey deeper into the 3s. Congratulations Kenny on building and driving your 3-second hot rod.