Proper fuel flow is of prime importance to automotive performance enthusiasts, especially to those who race. If you don’t have enough fuel flowing to an otherwise right-built engine, it will starve, can be damaged, and you will be very disappointed to say the least. Aeromotive has been working hard to make sure you have the right pump for the job.

Proper fuel flow is of prime importance to automotive performance enthusiasts, especially to those who race. If you don’t have enough fuel flowing to an otherwise right-built engine, it will starve, can be damaged, and you will be very disappointed to say the least. Aeromotive has been working hard to make sure you have the right pump for the job.

It’s new Terminator fuel pump first displayed at the 2014 Performance Racing Industry (PRI) show was the direct result of the demands of a racer. As a matter of fact, that racer was Aeromotive owner Steve Matusek, and he needed something a little more powerful with a higher flow rate pump for his 3,000 hp alcohol Pro Mod car. So the engineers at Aeromotive started experimenting with things like spur gear setups and different plate thickness, searching for the combination they needed to flow a fire hosing 24-gallons per minute.

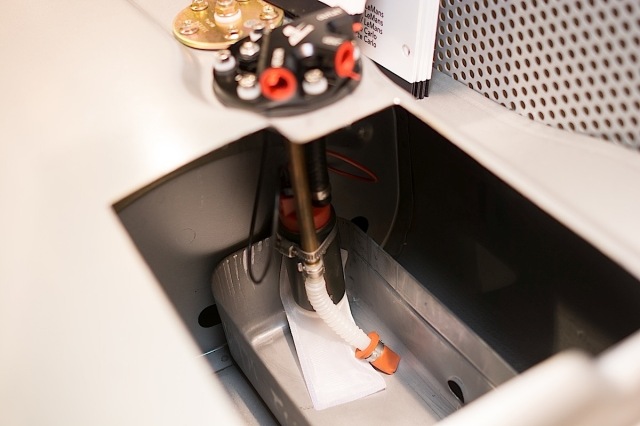

Jared Cox of Aeromotive said, “Once that was accomplished, we started to think about how can we could package it so it would be widely applicable. So we designed it to fit all the different AN connections, hose barbs, and ports. Now we have three- and four-bolt mounting collars, v-band clamps, and even shut-off valves. The Terminator pump can flow anywhere from 16 to 25 gallons per minute, and has allowed Aeromotive to break into a market it had never touched before. We have it qualified all the way up to nitro.”

The drive system for the Terminator fuel pump has a hex drive, so it can operate from any sort of hex drive system, such as a dry sump hex drive. Aeromotive offers the Terminator in everything from a 3/8-inch to 7/16-inch hex.

Phantom Advances

“The Aeromotive line of Phantom fuel pumps really started off with the Phantom 340 (that flows 340 liters per hour) and we decided we wanted to make an electric fuel pump that could work in gas tanks never designed for electric pumps,” said Cox.

Aeromotive engineers has to figure out how to get the lines out of the tank and get the pump into the tank, and also have to work out how to create a baffle with no welding. They decided to use a foam baffle system very similar to what the OEMs are using in daily drivers. “We released that to market and it was wildly successful, but we had people calling in and telling us that they didn’t need that much flow, so we came out with the Phantom 200 pump.”, Cox told us.

At the 2014 SEMA Show, Aeromotive showed off its recently developed Dual Phantom and Phantom Flex. The Flex is for those who want to run flex fuels such as E85. Aeromotive uses a 450-liter per hour pump with the Flex because the use of E85 demands about 30 percent more flow, and the basket was enlarged to handle the higher flow rate, and that meant the foam grew along with everything else to support the added flow.

The Dual Phantom satisfies those customers who want a 700-liter per hour flow rate for forced induction EFI engines in the 1,000-plus horsepower range. It has two 340 pumps coupled together so now it can handle get forced induction 1,400 hp engines.

Cox said, “With it you can have the ultimate sleeper fuel tank (a baffled EFI tank built at home), and the best part is they’re quiet, and you only have to run one at a time. You can stage them so the second pump is switched (such as an HOB switched with boost) or have your ECM control it. Or for off-road endurance race application, you can just use one and have the other as a back-up in case of failure.”

Whether you’re just retrofitting a street car and want the reliability of an electric fuel pump, or you’re racing a 3,000-plus horsepower Pro Mod beast, Aeromotive has you covered.

Whether you’re just retrofitting a street car and want the reliability of an electric fuel pump, or you’re racing a 3,000-plus horsepower Pro Mod beast, Aeromotive has you covered.