During the tuning process, the use of a dynamometer is essential, and Dynocom Industries aims to provide the tuner with a variety of ways to accomplish their goals.

During the tuning process, the use of a dynamometer is essential, and Dynocom Industries aims to provide the tuner with a variety of ways to accomplish their goals.

“Our electronics have been the same since the beginning, and we stress that when people are picking a dyno system because it’s something that makes their life simpler when tuning,” says Dynocom’s Kyle LeBlanc.

The company has a wide range of offerings. The catalog is filled by two-wheel to all-wheel-drive dynamometers; each one is managed by a handheld controller that can control every single fact of the dyno’s operation. “A single person can operate the dyno, they don’t have to have a standby operator, and the handheld takes all of the headache out of the tuning process,” says LeBlanc.

All of the electronics are included on all of the systems. The company makes many different sizes of dynamometer to accommodate everything from rear-wheel-drive vehicles to all-wheel-drive diesel vehicles, and they also have a a pod-style system that bolts to the wheels and does not require a roller for those shops that are space-challenged.

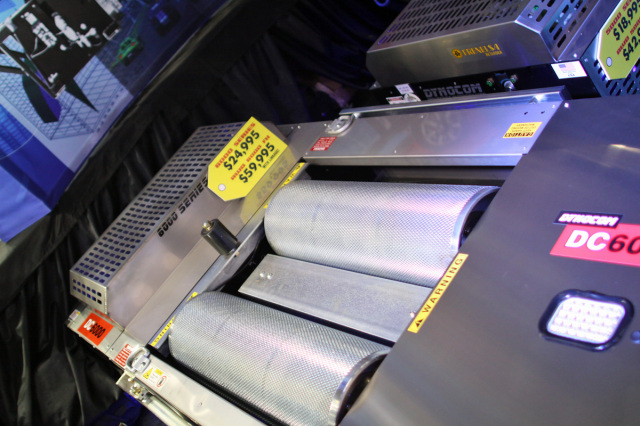

The company produces over ten different models of dynamometer, with the DC6000 their newest product. The DC6000 offers the aforementioned dual eddy brake and a cradle-style dual roller design, where there are two rollers on each side of the vehicle. The dual roller design offers simplicity during setup, as the operator can just settle the drive tires between the rollers, rather than having to perch the vehicle atop one large roller as with other designs.

“We make this dynamometer specifically for the diesel market; these guys have over 2,000 lb-ft torque. The dyno has extra knurling on the rollers to handle the traction and the additional braking force from the dual eddy brake,” says LeBlanc.

The dual eddy design has a pair of electric brakes that provide resistance, and the low-inertia design accelerates quickly and is sensitive enough to measure small changes. It’s designed to simulate driving the vehicle at normal road speed speeds, up a hill, and even under deceleration. It’s all controlled by the handheld and the standalone electronics. According to LeBlanc, the user tells the dynamometer what to do via the handheld, and everything is handled seamlessly in the background.

Other Notable Features

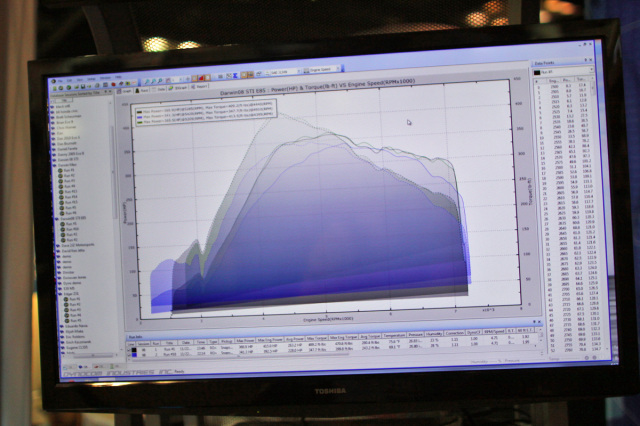

The software is a key part of the product.

“One of the new features we’ve added this year is to allow the user to control the sampling of data based on an analog input. The most common application is for someone testing a boosted engine; the software will automatically start recording the data and the operator doesn’t need to press a button. As soon as they hit the gas or the engine goes into boost. It’s constantly monitoring the analog input and make the decision to start recording data once the condition happens,” says LeBlanc.

Other additions are the automatic lubrication system and the retainer rollers built into the platform to keep the vehicle from accidentally rolling off the dynamometer.

An option for dual widebands is available; a single-channel unit is included with each of the dynamometer systems. The NTK sensors the company uses offer high accuracy and last longer than competing sensors. The wideband package is also sold separately.

An option for dual widebands is available; a single-channel unit is included with each of the dynamometer systems. The NTK sensors the company uses offer high accuracy and last longer than competing sensors. The wideband package is also sold separately.

Other available upgrades include a plug-and-play boost logging system, sensors and systems to datalog more parameters than the standard system, and even OBD-II logging that plugs right into the vehicle and logs all available OBD-II parameters right onto the dyno graph.

“We also provide training to each of our customers to instruct people on how to use the software. We do free training at our facility in Texas, or we’ll come to the user’s facility for an extra charge,” LeBlanc says.