The C8 Corvette has been a hot ticket ever since its release. Between the vehicle’s radically different styling and the awesome LT2 powerplant sitting behind the driver, the car has wowed everyone with its performance. The only downside has been when it comes to aftermarket forced induction systems. With GM’s high-level ECU security, no one has been able to seamlessly incorporate forced induction using the stock ECU — until now.

“We knew the C8 was going to be a popular vehicle to get more power out of, but it comes with some challenges,” says Magnuson Supercharger’s Grant Terry. We’re obviously very familiar with the LT1 and LT4. The LT2 is pretty much the same cylinder head pattern with a few subtle differences.” Packaging is an issue with such a compact engine bay, but the C8 provides more room than you might imagine.

Packaging in the C8 was a concern, but proved to be less constraining than the previous-generation C7’s low hood-line.

“Packaging is actually more of a truck-style kit than the one aimed at clearing the C7 hood. This allowed us to put a fairly large intercooler brick in the manifold,” says Terry. In addition to height issues, the drive arrangement for the Eaton TVS2650 rotor pack proved to be challenging. To solve it, they leaned on their experiences with the COPO Camaro supercharger program.

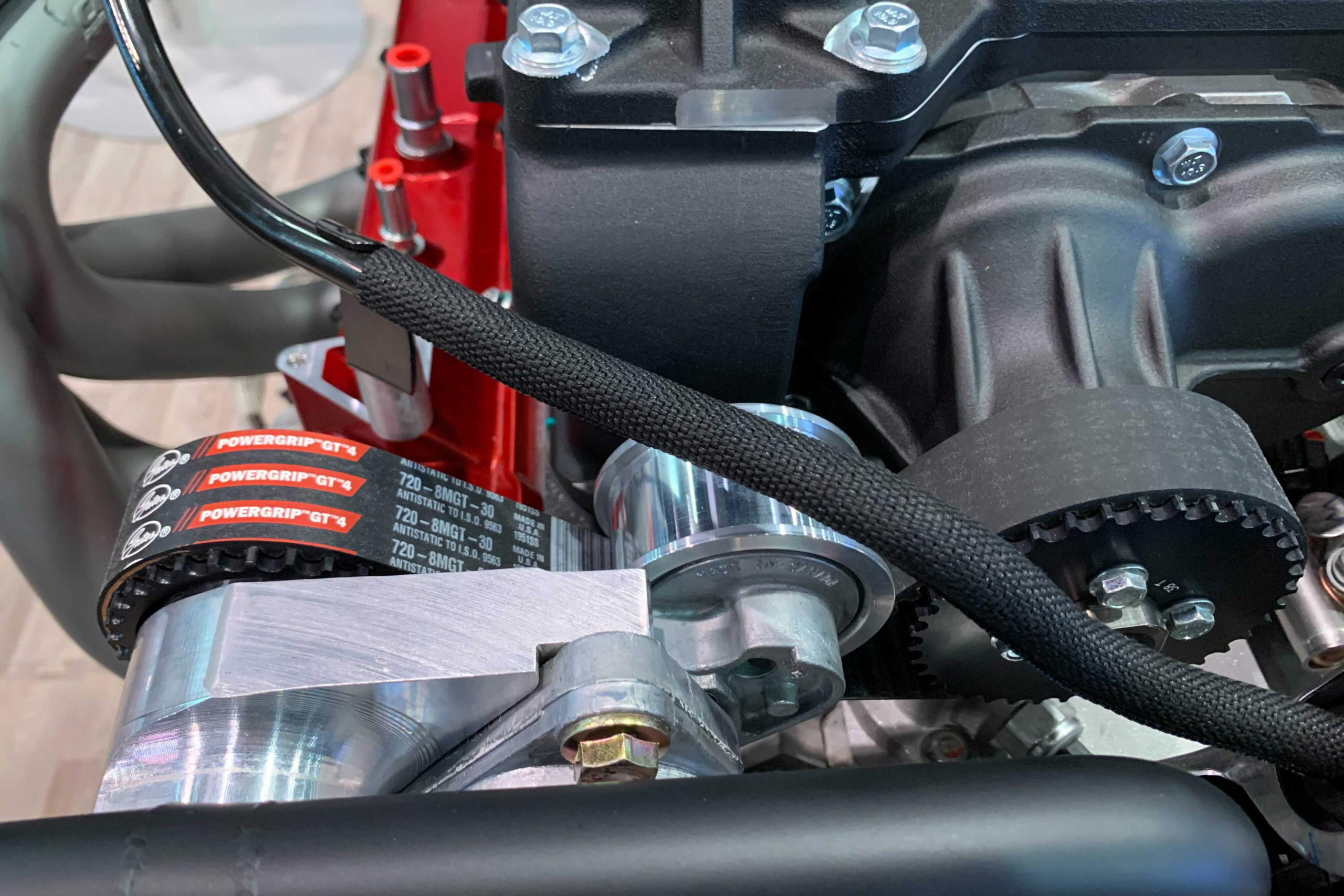

“When we started looking at the drive, it was clear that you can’t just hook a supercharger up to the existing beltline. What we ended up doing is coming up with a mini jackshaft system. It’s the same concept as what we do on the COPO Camaro, just about six inches long,” Terry explains. “Instead of a ribbed drive, we went with a cogged drive with an auto-tensioner.” Not only does the cog belt system increase service life, but allows them to use a physically smaller pulley without worrying about belt slip.

The factory accessory drive system didn't allow a lot of room to insert a new pulley, so they developed a "mini jackshaft system" similar to the COPO Camaro's supercharger system with a cog belt.

Additionally, the kit features what Magnuson calls “Dynamic Flow Tuning.”

“We learned a lot from the COPO Camaro program as it relates to tuning the inlet ports. Dynamic Flow Tuning allows it to change the inlet port shape on the supercharger to optimize for different driving conditions. We took advantage of that on this unit,” relates Terry.

However, the best-engineered supercharger system in the world isn’t worth its weight in aluminum if you can’t actually tune the engine. For that aspect, they teamed up with Lingenfelter Performance Engineering and their awesome new C8 Control System Module. “A big part of making this work is the control system from Lingenfelter. We can’t access the GM ECUs on this generation of cars. It’s encrypted and we’re locked out,” explains Terry.

The magic that allows the supercharger system to integrate into the C8 with a seamless, factory-style interface. The Lingenfelter C8 System Control Module connects the factory ECU to aftermarket tuning, but doesn’t actually alter the programming of the factory system at all.

“What Lingenfelter has done is developed a box that takes into account manifold air pressure, mass airflow, engine speed, and spark timing, and makes adjustments based on what it’s seeing, and then communicates that back to the ECU to make sure everything is happy. With this system, we don’t actually change anything in the ECU, which leaves you an untouched factory unit and calibration. It’s a seamless integration, really.”

What that means is the kit, as delivered, makes 705 horsepower at only 6-psi of manifold pressure, while driving with the OEM ECU untouched and intact, with factory drivability. If those numbers look low, it’s because they are designed around completely stock components. “The 2650cc supercharger is capable of moving 1,400 to 1,500 horsepower-worth of air, with the appropriate supporting modifications,” says Terry. This makes for quite a potent package for the C8.