When seeking a brake setup suited for spirited driving or potential track use, the primary consideration revolves around the brake pads. Essentially, brake pads deliver the necessary resistance against the rotor, and its compound or material can significantly impact stopping power. Yet, not everyone requires race-specific pads for spirited driving, and using durable street pads for the track might not be advisable. This is precisely why Disc Brakes Australia (DBA) offers a range of four options, from OE replacement to high-performance race series.

Doing Brakes As A Business

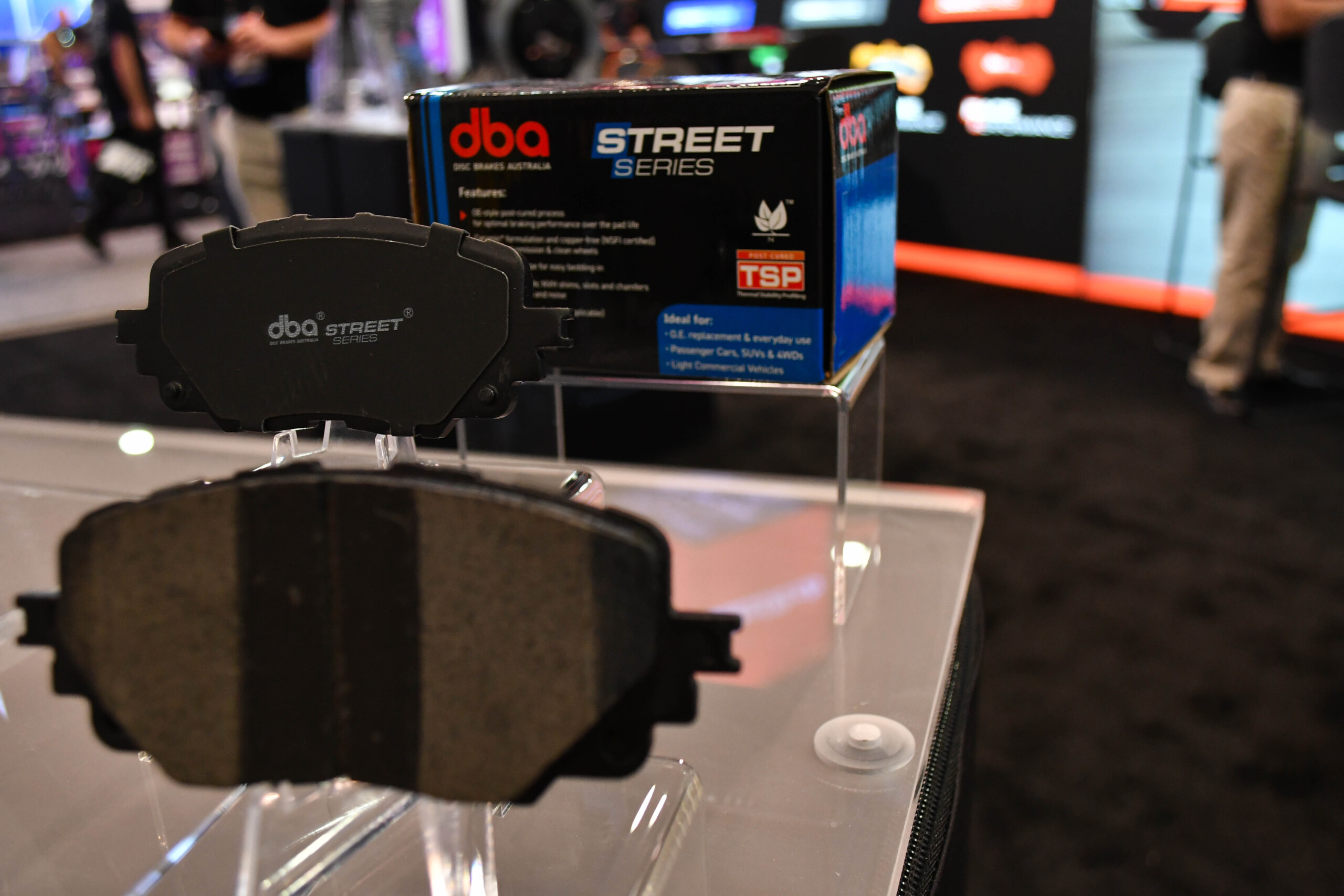

DBA categorizes its pads into four segments, catering to various automotive needs. The Street Series pad serves as an excellent OE replacement suitable for daily use in passenger cars and SUVs. For optimal performance, DBA suggests pairing these pads with their Street series disc rotors as an upgrade from factory rotors. Slightly surpassing the Street Series is the Street Performance, offering an upgrade from OEM pads while maintaining street-friendly characteristics. It’s advisable to pair these pads with DBA performance disc rotors for enhanced performance.

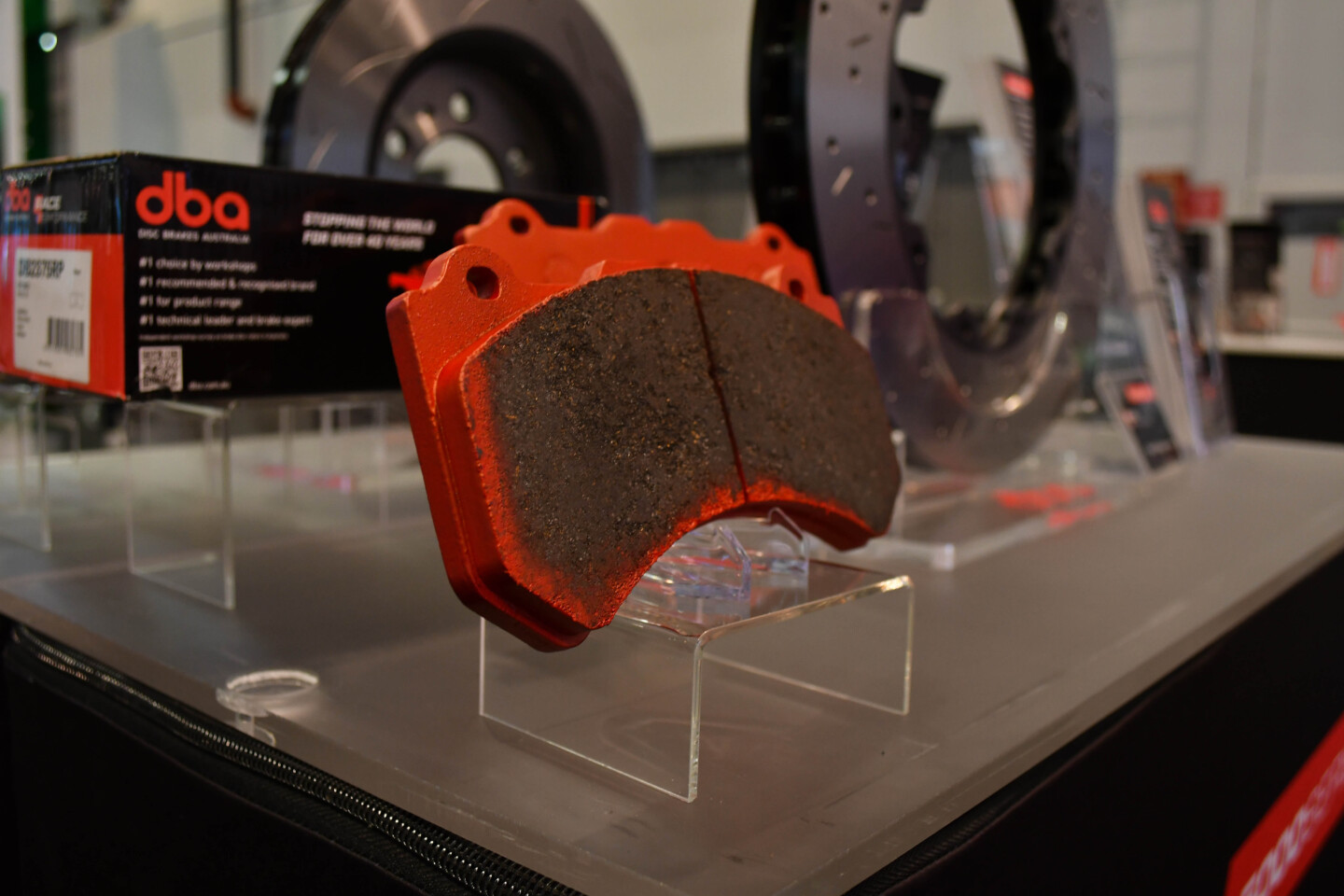

The excitement kicks in with the Xtreme Performance pads designed for street cars occasionally hitting the track. Once more, these pads are ideally paired with DBA performance disc rotors. Moving beyond street driving into track territory, DBA presents the Race Performance pad crafted for super sprints and circuit racing. Naturally, it’s recommended to upgrade to the DBA 5000 series high-performance rotors as well.

Getting Technical

Creating new brake pad divisions by altering compounds isn’t a novel approach, but DBA stands out by supporting its pads with a range of technical features. These brake pads include several technical enhancements: chamfer is geared towards reducing noise, vibration, and harshness, while slots contribute to maintaining temperature stability and clearing away debris. Premium quality shims are constructed with application-specific elastomeric coatings to minimize noise. The post-curing or scorching process (TSP) enhances cold friction effectiveness and minimizes bedding-in time.

The friction material is specifically engineered with compositions tailored for fade resistance, noise reduction, and performance. Additionally, the bedding-in stripe, infused with titanium, heightens the initial friction coefficient, enhancing initial stopping power and facilitating the mating of surfaces between the rotor and brake pad during the bedding-in process. These combined features ensure a comprehensive brake system optimized for reduced noise, improved performance, and enhanced initial stopping power.

Stopping On A Dime Or Sooner

Selecting a brake pad tailored to your specific motorsport needs is a smart decision. However, ensuring that the chosen pad incorporates advanced technology can not only improve lap times but also contribute to the safety of vehicles on and off the track. Don’t wait until your brake pads are nearly worn out before making necessary changes.