Have you ever seen the movie “The World’s Fastest Indian,” a wonderful feel-good tale of Burt Munro and his Bonneville-bound motorcycle? The flick starred Anthony Hopkins (that’s Doctor Hannibal Lector to slasher-movie fans), and one of the most memorable scenes, from a gearhead standpoint, was Munro casting his own pistons in his garage/shack/home.

Have you ever seen the movie “The World’s Fastest Indian,” a wonderful feel-good tale of Burt Munro and his Bonneville-bound motorcycle? The flick starred Anthony Hopkins (that’s Doctor Hannibal Lector to slasher-movie fans), and one of the most memorable scenes, from a gearhead standpoint, was Munro casting his own pistons in his garage/shack/home.

We try to minimize that process so there’s less room for error.–Anthony Quinn, Probe Industries

At its simplest, a piston is nothing more than a slug of aluminum that goes up and down in the engine’s cylinder bore, taking the abuse of the combustion process without melting or grenading into pieces. Hence, Burt Munro’s home-cast slugs were adequate for his application; sort of, but that was backyard hackery even for the early days. Today’s pistons are much more complicated works of engineering, that depend on precise manufacturing methods and materials, yet be flexible enough to provide the engine builder with options to meet specific applications.

Shown left are two examples of the blank forgings, depending on piston size and type. Right: This raw forging has been cut with four small marks at 90-degree intervals to locate the slug for pin hole rough machining. This is an FPS piston, indicated by the forged, not machined valve pockets.

Focusing on pistons

Custom Pistons

For custom pistons, Probe can work off a customer’s computer rendering or partner with them to generate a piston based on strictly defined needs — such as special ring packages, compression height, dome height, combustion chamber design, and so on. The only limit is the ability of the piston to be machined out of an existing forging, of which Probe selects from four basic types. Possibilities also include pistons for imports, vintage engines and motorcycles. Custom options include forced pin oilers, or grooves between the oil ring groove and pin hole that help lubricate the piston pin.

Probe Industries is a popular piston manufacturer based in Torrance, California, that was established by Mark O’neal in 1987. Probe used to manufacture main and stud girdles, rocker arms and other associated parts, but a recent paradigm shift has the company focusing solely on building pistons in a time-efficient process to keep costs low. And that’s one positive note they emphasized while touring the facility — the company’s production process requires fewer steps and therefore fewer machines and less time.

“What’s different about us is that we try to minimize that process so there’s less room for error and the pistons are more consistent that way,” says marketing manager Chris Petrini. “All of our pistons can be more precise, across the board. The shortest process involves just three steps and the longest requires five or six steps.”

Every Probe piston is built in the USA—even the raw forgings come from a foundry in the US. So how does Probe build a piston from scratch? We toured the shop full of CNC mills and lathes to find out, and picked the brain of Anthony Quinn, Probe’s production manager. Quinn handles all the machine setup, tooling, and CNC programming, as well as overseeing the whole production process and quality control.

Probe generally focuses on producing the pistons in its catalog; in other words, the most common, popular parts with an emphasis on sales to wholesalers, distributors and private label clients. However, Probe will perform custom work, depending on customer needs.

Probe recently launched a line of small-block piston pins and will expand to BBC models soon.

Following the manufacturing process

A new piston design begins on the computer in a Mastercam program that allows Quinn to draw up a profile, which is then translated into code for the CNC machines. Once the design is set on the computer, the work continues in the machining center. The first step is to take the raw forging and machine register marks to locate for the pinhole. Once the pin hole goes in, then the piston is “set” for machining—everything goes off of the pin hole and register marks. During the pinhole rough machining process, the Spirolock grooves and broached oiling grooves are added.

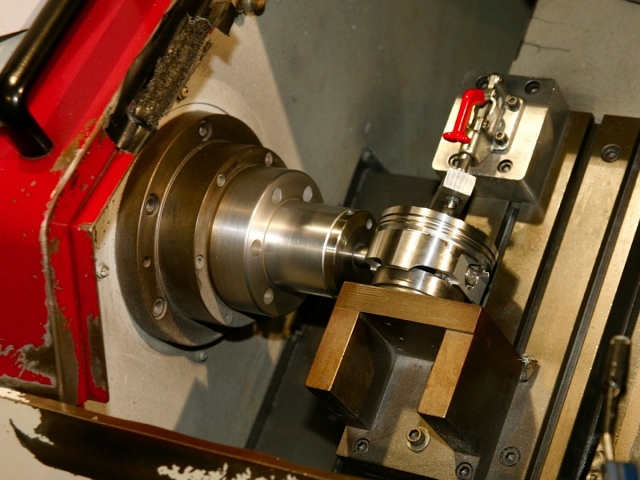

This big CNC is technically the first stop in the machining process. The pin hole and tiny register marks (visible on the underside of the pin boss) sets the piston for its remaining machining operations. On the SRS pistons, the valve pockets and/or dish profiles are machined here.

This lathe is the second stop. It performs all of the turning operations (such as for finished bore diameter), ring grooves, ring lands, faces the top of the piston, cuts a dish (if applicable) and finishes the skirt with Probe’s diamond cutter. This process leaves a ribbed surface to enhance lubrication and extend skirt life. The diamond tools also help maintain tolerances in the ring grooves to promote cylinder sealing.

The second step is to take the slug to the CNC lathe, where the bulk of the machining is done in one process. Some other piston manufacturers put in the ring grooves first and rough some things out, then go back and turn the skirt, piston top or face, etc, but Probe does it all in one step. Here, the valve pockets are cut, the profile is shaped (height, bore, etc.), the ring grooves, ring lands finished, the top is faced, a dish is machined (if applicable), drain back holes and Probe’s anti-detonation grooves are cut, and the skirt is finished with a diamond cutter — all in one step.

The last machining step is to finish the pin-bore diameter. In the first step, the bore was rough drilled, but cut undersize before the final bore, and on this machine it gets finished with a diamond cutter for the exact pin bore diameter and a near-mirror finish.

The skirt is the last part of the process because it’s the highest tolerance part of the piston save the ring grooves. After the initial run on the machine, the piston gets a “stress relief,” in Quinn’s words, where the machine releases then re-clamps the piston with a lower pressure to just hold the tolerances within spec. All of these machining steps are done on this one machine, which is one of Probe’s manufacturing advantages.

“Some companies run two to three steps in a lathe, but I believe our minimal step process gives less room for error. The more steps you have, the more you move away from your original design, the more room for error there is. That’s what makes us different,” says Quinn.

Left: This close-up shot demonstrates some of Probe’s precise machining operations. Between the face (top) of the piston and the first ring groove are anti-detonation grooves that temper pressure spikes and helps keep the top ring alive. Between the top and middle ring grooves is a pressure equalization channel that helps ring seal. Right: Shown here is the diamond-cut finish of the piston skirt, which Probe feels improves skirt lubrication and product life.

The last step is finishing the pin bore diameter, which is cut undersize in the first step for location purposes. A diamond cutter in the CNC machine finish bores the pinhole and provides a near-mirror finish and a true and concentric bore for tight tolerance holding. At this point, the pins are oiled and slipped into place, and the piston moves to the boxing and shipping department.

Probe offers two types of pistons: the Factory Performance Series (FPS) and Sportsman Race Series (SRS). Both are fully machined forgings (not cast or hypereutectic, like most factory pistons), and they differ in material and applications. You can probably guess by the name that the SRS is the more hardcore-oriented piston, built with a stronger but softer alloy (2618-T61) and a narrower ring package. The FPS pistons are still strong and will take boost or nitrous (within reason, like any piston) and are made from VMS-75 high silicon aluminum forgings. The FPS line eliminates a step in production by having the valve pockets forged into the raw blank, allowing them to be more affordable.

Left: An overall view of the machining center at Probe Industries. On the top right is the engine building area for Coast High Performance, showing the relationship between the two companies. Right: After the pin bore is finalized, a new pin is oiled and installed, then the piston is wrapped and boxed for shipment.

There’s only so much you can change on a piston. It has to fit the bore (obviously), be round, have 3 ring grooves (unless it’s a weird Stock class cheater piston), and be made of aluminum, so whether it’s short, tall, big or small, the difference between piston manufacturers lies in the machine work performed, materials used, and cost to the end consumer.