A few weeks back, we published a news item with some information about the then, upcoming Forty Eight Hour Corvette build taking place at the Ridetech build center in Jasper, Indiana. We were also fortunate enough to speak with Bret Voelkel, President of Ridetech and gain a little insight into what we could expect to see as far as participants and their strategies for the build.

A few weeks back, we published a news item with some information about the then, upcoming Forty Eight Hour Corvette build taking place at the Ridetech build center in Jasper, Indiana. We were also fortunate enough to speak with Bret Voelkel, President of Ridetech and gain a little insight into what we could expect to see as far as participants and their strategies for the build.

While the challenge may seem rather daunting to most, you have to remember that the folks who showed up, chomping at the bit to work on the car were some of the best that our industry has to offer. Additionally some of the team members already had similar experience from working on the first Forty Eight Hour Camaro in 2011.

According to Voelkel, “The original 48 hour concept came about at the 2010 SEMA show during a discussion about there being so many parts available for early [gen] Camaros, that you could bolt one together in a parking lot in a weekend.”

For those that haven’t seen it, the team was able to produce one impressive, track ready car in the blink of an eye. We have all seen the shows where they turn a car around in record time, but Ridetech decided to take on the challenge of not only building a car in 48 hours, but creating a car that was both comfortable and mechanically sound enough to drive to a road course, run the car competitively, and drive it home.

Logistics were one of the first questions we had going in, to which Voelkel explained, “The primary build crew will consist of three teams of three people each. One team will be working in the engine bay, one team under the car, and one team inside of the car. Each team will have one person designated as the team leader – he gets to make the decisions and will expedite any problems with components, fabrication, or tools.”

As we saw during the build, this turned out to be a rather effective way to work on the car as the teams were able to stay out of each other’s way rather successfully. Not every company was able to send an inside rep to install their particular part, but the capable hands onboard combined with some of the best products the Corvette aftermarket has to offer made most of the installations relatively quick and painless.

While the amount of talented hands on deck certainly exceeded those listed here, Voelkel mentioned a few of the guys that were lucky enough to personally install their parts on the C3. Those included, “Rick Love from Vintage Air with the A/C installation, John McCloud from Classic Instruments on the gauges, Michael Manning from American Autowire did the wiring, Mike Copeland from Lingenfelter installed the engine package, Mark Bowler with the transmission, Will Baty from Centerforce handled the clutch, Gabi Baer and Rick Elam from Baer Brakes handled braking needs, and Robin Lawrence from Holley artfully tuned the EFI.”

While we were able to learn more from Voelkel about the previous Camaro, the build teams, and and how they planned to execute the mammoth goal; we were not given much detail regarding which components were going to be used. Now that we know, we figured we should shed some light on them, as this Vette is now sporting some very impressive hardware.

Lingenfelter LS7 427 ci, 650 hp

- 11.5:1 compression ratio for 93 octane fuel

- GM LS7 7 L aluminum block

- JE forged aluminum pistons high tensile 2618 T6 alloy

- Total Seal Premium file fit rings

- Callies 4340 forged steel Dragon Slayer crankshaft -58x reluctor

- Oliver 4340 billet steel 6.125 I-beam connecting rods

- Clevite heavy duty HN rod bearings

- Federal-Mogul Speed-Pro heavy duty main bearings

- Lingenfelter LS three bolt cam conversion kit (L200175307)

- GM crank gear & HD timing chain

- Lingenfelter GT21 hydraulic roller camshaft (L210146006)

- GM LS7 dry sump oil pump

- GM keyed harmonic balancer

- GM LS7 lifters, lifter guides

- Corvette LS7 dry sump aluminum oil pan

- C6 Corvette valley cover, valve covers

- C6 Corvette rear cover

- Multi-layer steel (MLS) cylinder head gaskets

- GM head bolts, crank bolt

- Lingenfelter CNC ported & polished LS7 cylinder heads

- LPE Ferrea double valve spring kit (L230036006)

- GM LS7 2.205 diameter titanium intake valves

- GM LS7 1.615 diameter hollow stemmed sodium filled exhaust valves

- Competition Cams HD pushrods

- GM LS7 roller rocker arms, rocker arm stands, bolts

- LS7 Corvette composite intake manifold – fuel rails

- 90 mm throttle body, electronic

- 50 lbs/hr at 58 psi (four bar) fuel injectors

- LS7 coils

- Magnacor spark plug wires

- LPE logo Koolsox wire protectors

- LS9 iridium spark plugs

When it came to putting all of that massive power to the ground, they knew they would need a transmission that could not only take the on-track abuse, but needed great drivability as well. Bowler Transmissions took a Tremec T-56 Magnum Series, built for LS Motors and made a few modifications.

The gear box was fully autocross and road race prepped and received a few parts that will really make it shine including: an LS-style input shaft, a 26 spline input / 31 spline output with the following gears 2.66, 1.78, 1.30, 1.00, .80, .64, an updated second gear design, an updated 1-2 syncronizer hub design, and a full carbon blocker ring set for first and second position, while third through sixth and reverse positions received an all new carbon / hybrid blocker ring set.

The gear box was fully autocross and road race prepped and received a few parts that will really make it shine including: an LS-style input shaft, a 26 spline input / 31 spline output with the following gears 2.66, 1.78, 1.30, 1.00, .80, .64, an updated second gear design, an updated 1-2 syncronizer hub design, and a full carbon blocker ring set for first and second position, while third through sixth and reverse positions received an all new carbon / hybrid blocker ring set.

In order to make the new transmission fit, the tunnel had to be cut out, and a preformed fiberglass shell was then patched in its place.

Instrumentation

While it may not typically get the initial attention of a new engine build or a paint job, you will ultimately rely on your vehicle’s instruments to relay messages about its health and running conditions. Additionally, gauges can open a door for some increased customization that is unique to only your car. So for this build, Classic Instruments took it to the next level by matching the gauge faces to the exterior color and even included a few appropriate logos, a very nice touch.

The Suspension

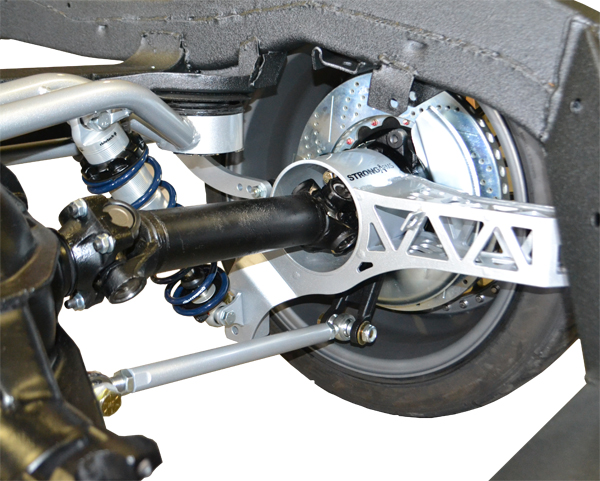

The Forty Eight Hour Corvette was equipped with a RideTech Level 3 Coil Over Suspension System. This kit is comprised of tubular StrongArms for optimized strength and proper alignment, RideTech spindles optimizing camber gain for better handling, billet steering arms which eliminate bump steer and optimize Ackerman angles, a Tru Turn steering linkage for proper steering geometry, StrongArms, Delrin control arm bushings that offer a more stable, smooth, and quiet ride, and TQ Series Mono-Tube Coil-Overs which increase driver tunability while improving ride and handling on the street and track.

Moving to the rear, they installed a tubular cross-member to allow the installation of offset, and fabricated trailing arms that offer more tire clearance and increased strength and durability. The camber links are relocated for increased camber which leads to better handling. RideTech’s own MuscleBar keeps the car flat on the track with added tuning thanks to the adjustable link mounts. Finally, another pair of TQ Series Mono-Tube Coil-Overs were installed.

The Binders

Lord knows we all love horsepower and generally speaking, lots of it. While a good top speed and quick acceleration are very important to a competitive road and track car, slowing all that muscle down is equally as important, if not more so. Accordingly, Baer brakes decided to install their 13-inch Front Pro+ Brake System.

Lord knows we all love horsepower and generally speaking, lots of it. While a good top speed and quick acceleration are very important to a competitive road and track car, slowing all that muscle down is equally as important, if not more so. Accordingly, Baer brakes decided to install their 13-inch Front Pro+ Brake System.

According to Baer, this system is comprised of the 6P six-piston calipers mounted to 13-inch, two piece slot, drilled, and zinc plated rotors, stainless steel brake hoses, as well as calipers that have D.O.T compliant dust and weather seals. Quality SKF or Timken bearings are used along with NAS high grade stainless hardware.

For the rear end, they selected the 13-inch Rear Pro+ Brake System which carries all of the same features listed above. Additionally, the rear system is designed to re-use the factory rear parking brake assembly. Don’t use those transmissions as kick-stands folks!

MSD Brings In the Air and Ignites It.

The all-new MSD Atomic AirForce intake manifold delivers improved airflow and distribution which improves fuel economy and overall performance of an engine. Accordingly, they figured it would make for a great fit on the Forty Eight Hour Corvette.

MSD explained that the unique bell-mouthed runner entrances maximize airflow and minimize shrouding compared to conventional manifolds. This design also optimizes the available plenum volume for an unobstructed flow path over opposing runners. Additionally, the polymer molded two-piece design allows for easy access to the runners for porting, should you want to modify your own unit.

MSD explained that the unique bell-mouthed runner entrances maximize airflow and minimize shrouding compared to conventional manifolds. This design also optimizes the available plenum volume for an unobstructed flow path over opposing runners. Additionally, the polymer molded two-piece design allows for easy access to the runners for porting, should you want to modify your own unit.

A car won’t get far without air and fuel, but equally as important is an engine’s ability to ignite the charge, and do so with extreme consistency. MSD’s Multiple Spark Coils (MSC) fit in place of the stock coils and connect directly to the factory connectors. These made for a very simple installation on the Corvette leaving little to chance. MSD also explained that an increased spark energy and voltage, along with multiple spark capabilities, help improve the combustion process of the fuel mixture to create an efficient burn. This results in improved throttle response, smooth idle and quick starts, in addition to increased high RPM performance.

New Colors For The C3

One of the questions we were asking ourselves–and you may be doing the same–was how do you prep, prime, paint, and clear a car in 48 hours when you already have a daunting list of mechanical work that needs to be completed? Simple, you wrap it. After some minor body repair, sanding, and door gap alignments, a team arrived to wrap the car in a beautiful glossy yellow color scheme, you’d never know it wasn’t paint.

The Fat Lady Sings

By now your heads are probably spinning, wondering how all of this technology performed and if the new C3 was doing burnouts in the parking lot as the Forty Eight Hour Corvette countdown clock hit zero.

Well, sadly we have to report that the car was still sitting on jack stands as the clock struck 00:00. The “glass is half empty” crowd may look at this as a failure, but we would have to strongly disagree with those folks.

Well, sadly we have to report that the car was still sitting on jack stands as the clock struck 00:00. The “glass is half empty” crowd may look at this as a failure, but we would have to strongly disagree with those folks.

Those Monday morning, armchair quarterback types rarely, if ever, reach for challenging goals, which remind us all about the words of Wayne Gretzky who said, “You miss 100-percent of the shots you don’t take.”

The fact of the matter is that while it may have taken a few hours longer than planned, Ridetech and the entire team put on one hell of a show and built a car that any shop would be proud of, much less one that was constructed in a few days.

So how did it perform you’re wondering? Take a look at this…

We are sure that this car handled as good as it looks, and while the video leaves a lot to be desired, we believe this was intentional as this car should receive a lot of future coverage as it competes in various events throughout the country in the coming years. Not to mention, we just had to re-watch the sliding burnout at the end of the video!

Corvette Online would personally like to thank every person who contributed to or supported the Forty Eight Hour Corvette build and say congratulations on a job well done.