It wasn’t that long ago that 1,000-plus horsepower engine was a remarkable achievement. If you had a racecar in the 80s or even the 90s that was capable of producing quadruple digits you were a force to be reckoned with, and a street car with that much power was almost unheard of. As technology advanced Chevrolet introduced the now-legendary LS platform in 1997. Before that, the standard small-block and big-block engines suffered with reliability issues from two and four bolt mains, weak pistons and rods, and flow-restrictive heads. All of these issues were addressed in the LS engine which resulted in a superior small-block that could take way more abuse than it’s predecessors.

Chevrolet has now ditched the GEN IV LS in favor of the even more advanced GEN V LT lineup. The LT still utilizes the LS foundation but improvements have been made. It offers a tenacious rotating assembly consisting of a forged crankshaft, powder metal forged rods, and forged pistons in the LT4’s. The result of this combination is an engine that can take even more of a beating than the LS. Lingenfelter Performance Engineering saw the LT4 platform as a huge opportunity; they wanted to create a line up of parts and create the ultimate ZL1 street car package that was still very reliable and street-mannered.

In a effort to push the ZL1 to an unknown territory, the Lingenfelter “Eliminator Series” was born. Mark Rapson, Lingenfelter’s COO/VP Operations stated,”The Eliminator Series encapsulates our newest generation of performance parts and packages. The ZL1 was the development vehicle for the components, however its not limited to the Camaro. The Eliminator Series of performance parts will be applicable across all or our platforms car and truck.”

After dynoing the Zl1 for a baseline, Lingenfelter starts with the removal of the stock 650-horsepower, 650lb-ft of torque LT4 engine. At this stage the heads are removed and then CNC-ported and polished at the Lingenfelter facility before being reassembled. The OEM solid titanium 2.125-inch intake valves and sodium filled steel 1.590-inch exhaust valves are still utilized, but not before a three-angle valve job is finished. They also take the heads to the next level by hand blending of the valve seats before assembly utilizing the companies own dual valve springs, titanium retainers and 10-degree locks. The camshaft is yanked and replaced with a GT31 LT4 hydraulic roller camshaft offered by Lingenfelter, as well.

Here are the primary components on the ZL1 which fall under the Eliminator Series line of performance parts:

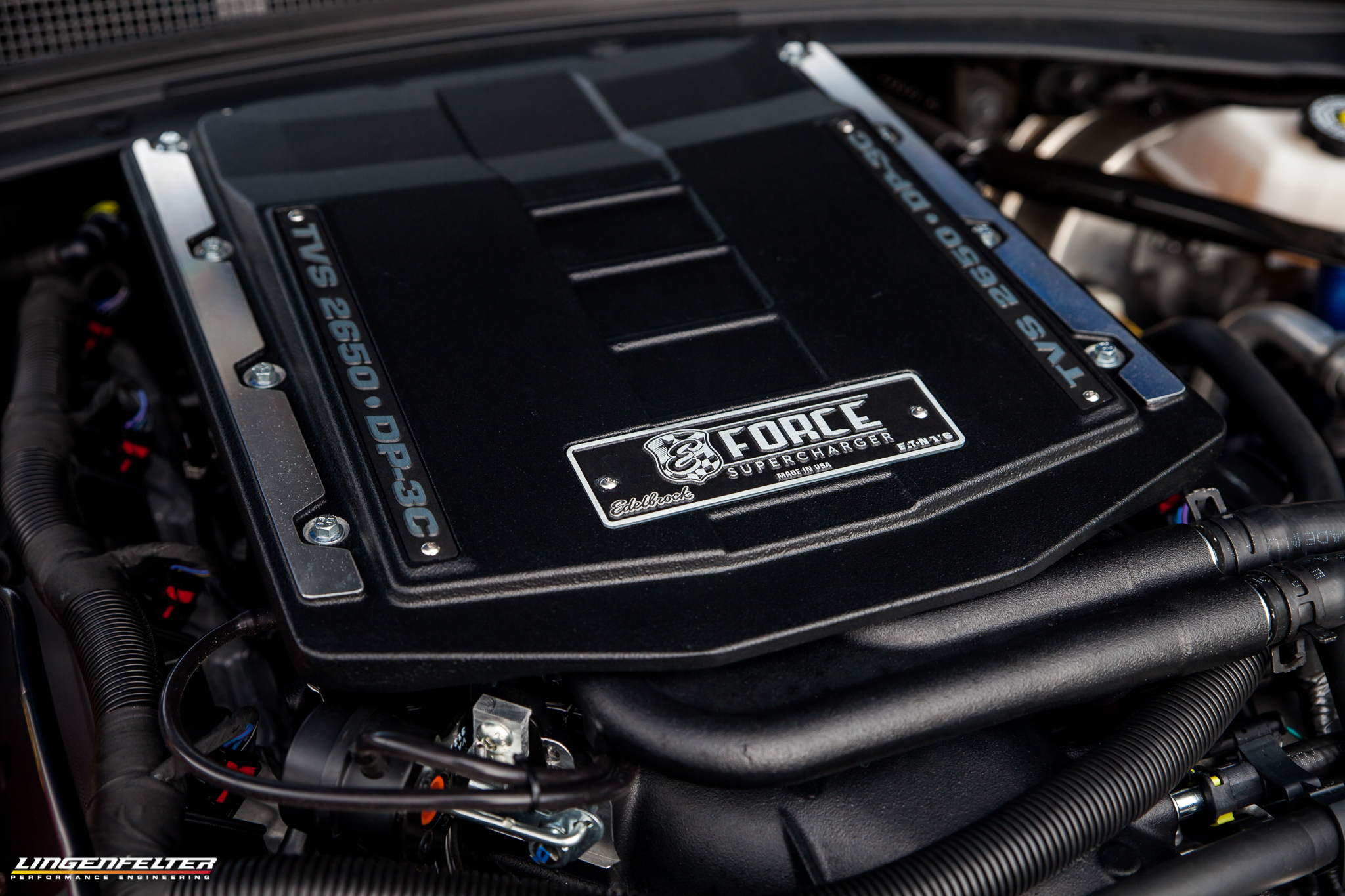

- Lingenfelter Edelbrock TVS2650 supercharger

- Lingenfelter 12mm Big bore DI pump

- Lingenfelter K-DI high flow injectors

- Lingenfelter high flow in-tank pump system

- Lingenfelter GT 31 cam with special fuel lobe

- CNC ported heads specific to the new 1000 HP package

- Lingenfelter Logo Koolsox Spark Plug Wire Thermal Heat Protectors

- GM Performance rear brake kit

- Lingenfelter Kooks performance exhaust system w/performance CATS

- Lingenfelter dual solenoid line-lock system

- GM performance Weld race wheels

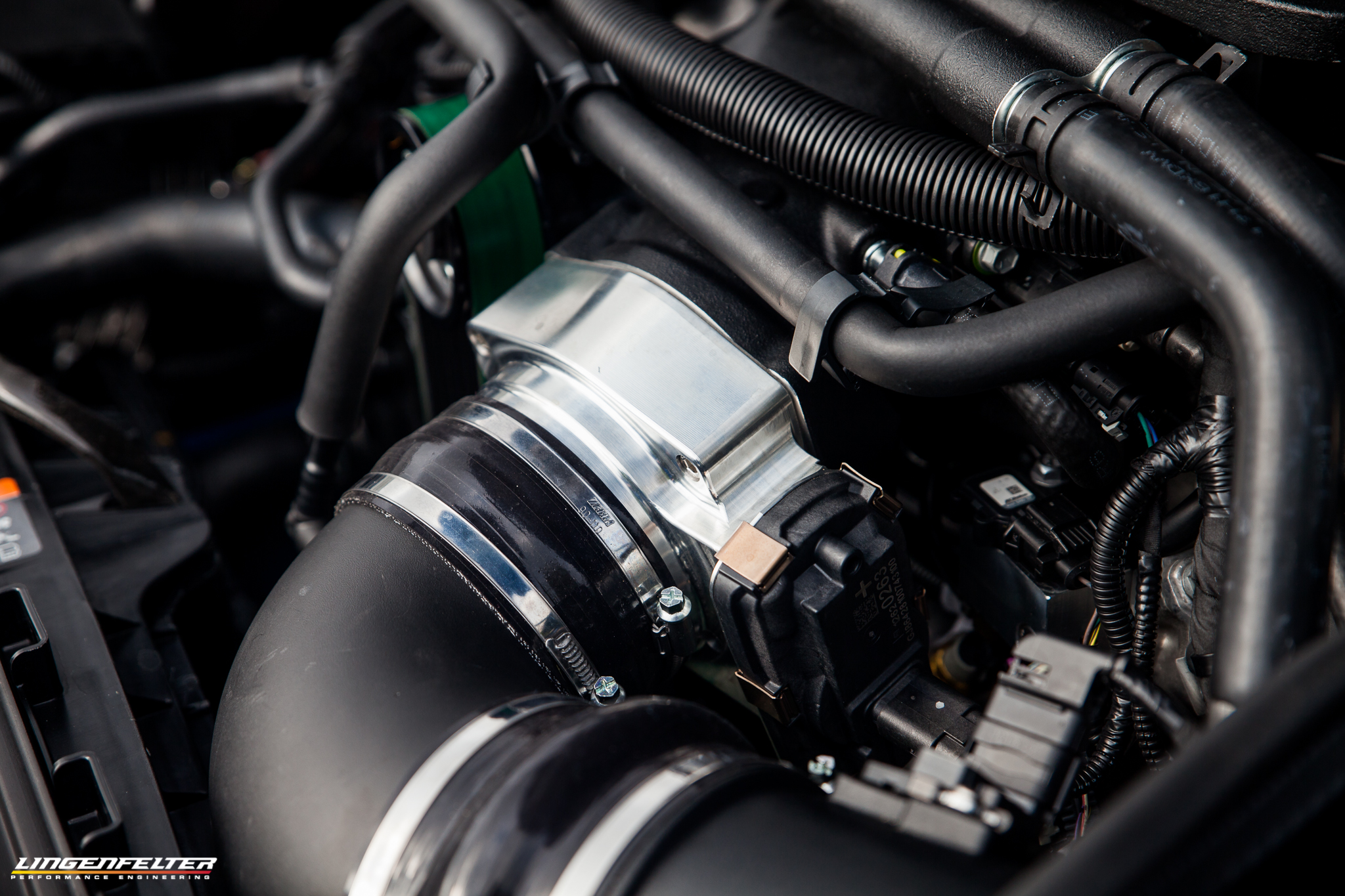

The Edelbrock TVS2650 supercharger with a ported and polished 103mm throttle body will now replace the overworked factory unit to make the power needed. The ZL1 will also get Lingenfelter’s new K-DI high flow injectors that feature Nostrum’s patented K-DI Kinetic nozzle geometry, fuel pump, and an E85 ethanol sensor upgrade. A set of Kooks long tube headers and high-flow catalytic converters will make sure the exhaust gasses move freely and keep restriction at a minimum. With the addition of the headers Lingenfelter wanted to make sure the plug wires would live under the harsh environment and installs a set of Koolsox spark plug wire thermal heat protectors for longevity.

After the engine is back in and at home between the fenders of the ZL1, the crew will reprogram the engine control module. Then the Camaro will be dynoed to make sure everything is superb and the new parts are doing their job. After this has been confirmed and everything is good, Lingenfelter will rebadge the the fenders and include a personalized stainless engine badge with a certificate of authenticity. The car will go through a four wheel alignment, cleaning and detailing, and will be topped off with a full tank of 93 octane.

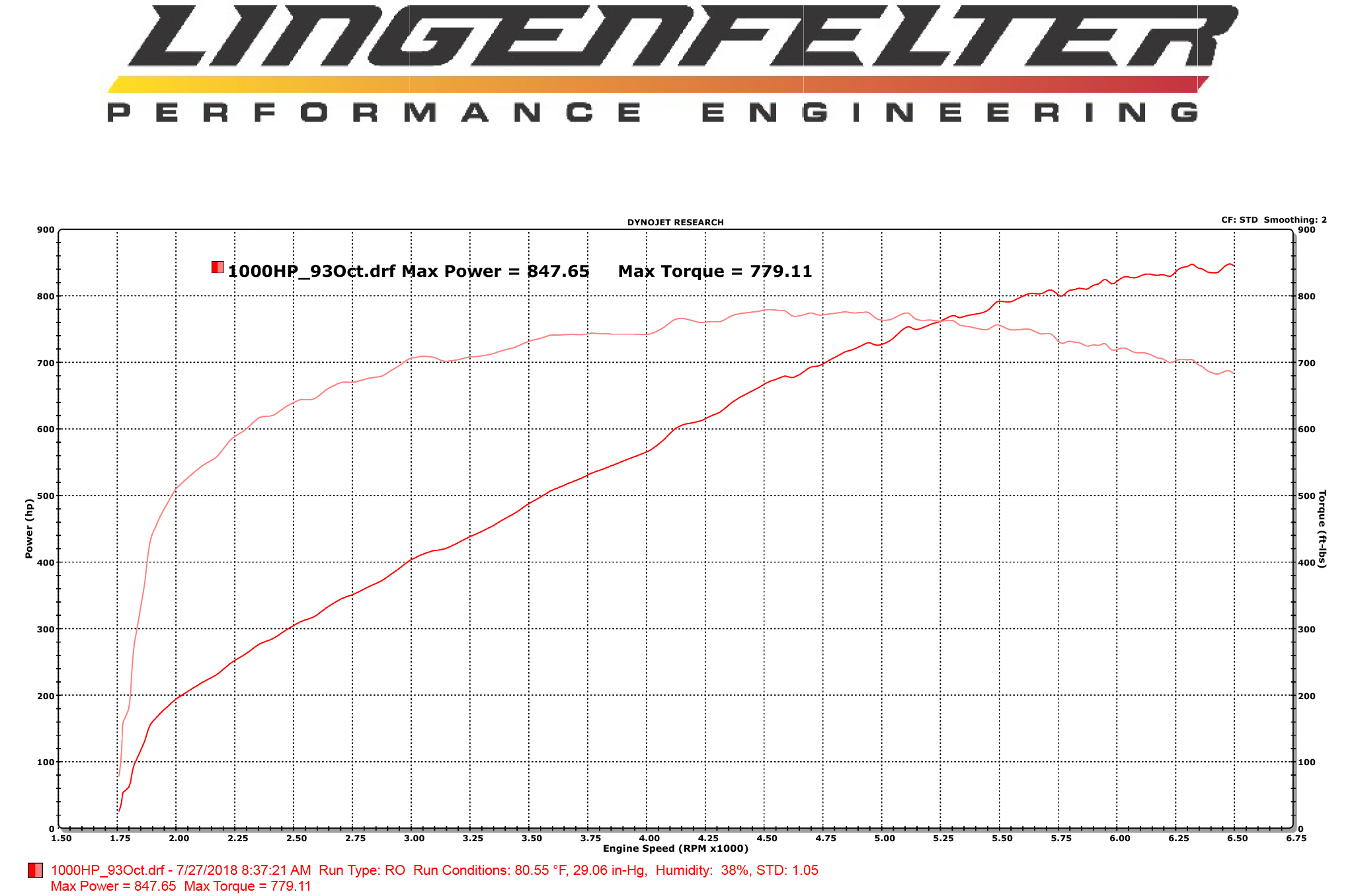

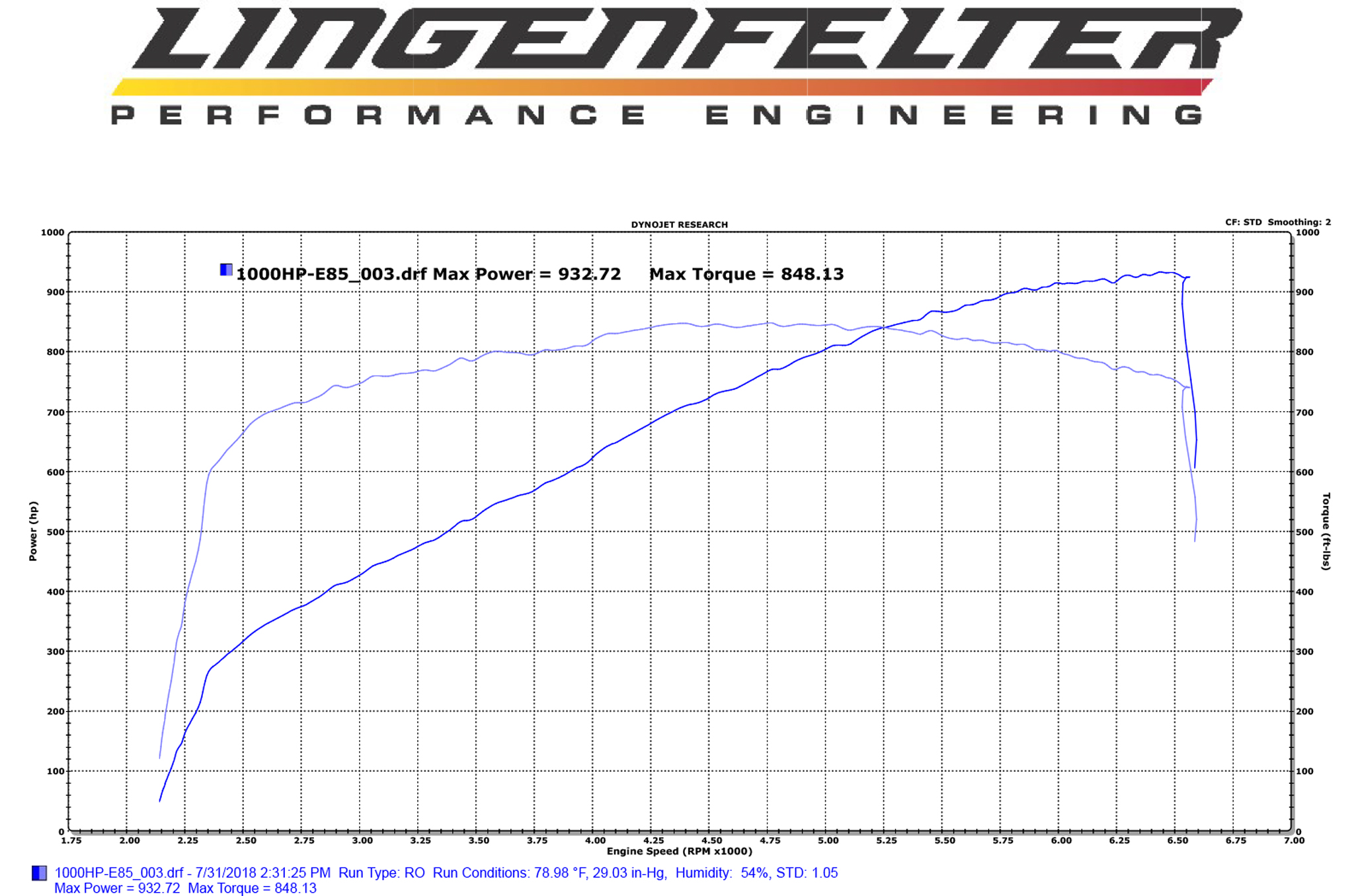

So how much power can you expect to make with this new package on 93 pump gas with a stock LT4 Bottom end? With the Eliminator Series components, the Lingenfelter ZL1 1,000 horsepower package was able to make 1,000 horsepower and 866 lb-ft of torque at flywheel! While this is a huge achievement, the newly developed parts allowed the car to achieve outstanding performance while maintaining unmatched street manners with incredible drivability. This combination has run a best of 9.68 in the quarter mile with the best speed to date of 147.8 mph. This is a mid 9-second car that is just as comfortable on the street as it is a racetrack. According to Mark, they are just getting started, “We have only done one test session with the ZL1 and we know there is more in it.”

We can’t wait to see how much more the Lingenfelter group can squeeze out of the Camaro and to see what new Eliminator Series parts are in the works. One thing is for sure, the LT4 package from Lingenfelter takes a great factory car and turns it into a killer 9-second ride without sacrificing drivability all while sipping on 93 pump gas. It just doesn’t get any better than that, but it just might.