When it comes to LS engines, it seems like “junkyard” and “stock bottom-end” builds are all the rage. And while it’s true that you can slap a turbo on a stock LS and make stupid power, it’s usually a ticking time bomb. That is unless you do it right. And by “right,” were talking about Jack Roberts’ 4.8-liter LR4 engine, which has been into the sevens, and makes well over 1,000 horsepower. Oh, and it has stayed together for an entire season and counting.

Usually, when claiming a record within a sanctioning body, there are protocols to follow to verify and validate the claims, both from a performance and a rules-compliance standpoint. However “stock bottom end” isn’t defined in any rulebook that we’re aware of, and when something isn’t spelled out in black and white, many people will venture into the gray areas.

Interestingly enough, Roberts didn’t set out to set the world on fire and wasn’t even gunning for the stock-bottom-end record. “My original goal with the project was just to build something that I felt was fast enough to scare me. Also, to help me learn how to tune a 1000-plus-horsepower LS engine. I didn’t want to experiment on customer cars so I figured I would build my own and use a cheap motor so if I did mess up it wasn’t a huge loss,” says Roberts, the owner of Squirrel Tuned.

I originally picked the 4.8 only to be a troll. Almost every time an LS car would beat a Coyote car online, you see comments about the ‘big LS’ needing all that displacement. When I got with John Bewley to spec the combo, the record was in my mind but I had no real expectations of getting there.”

Stock Bottom End

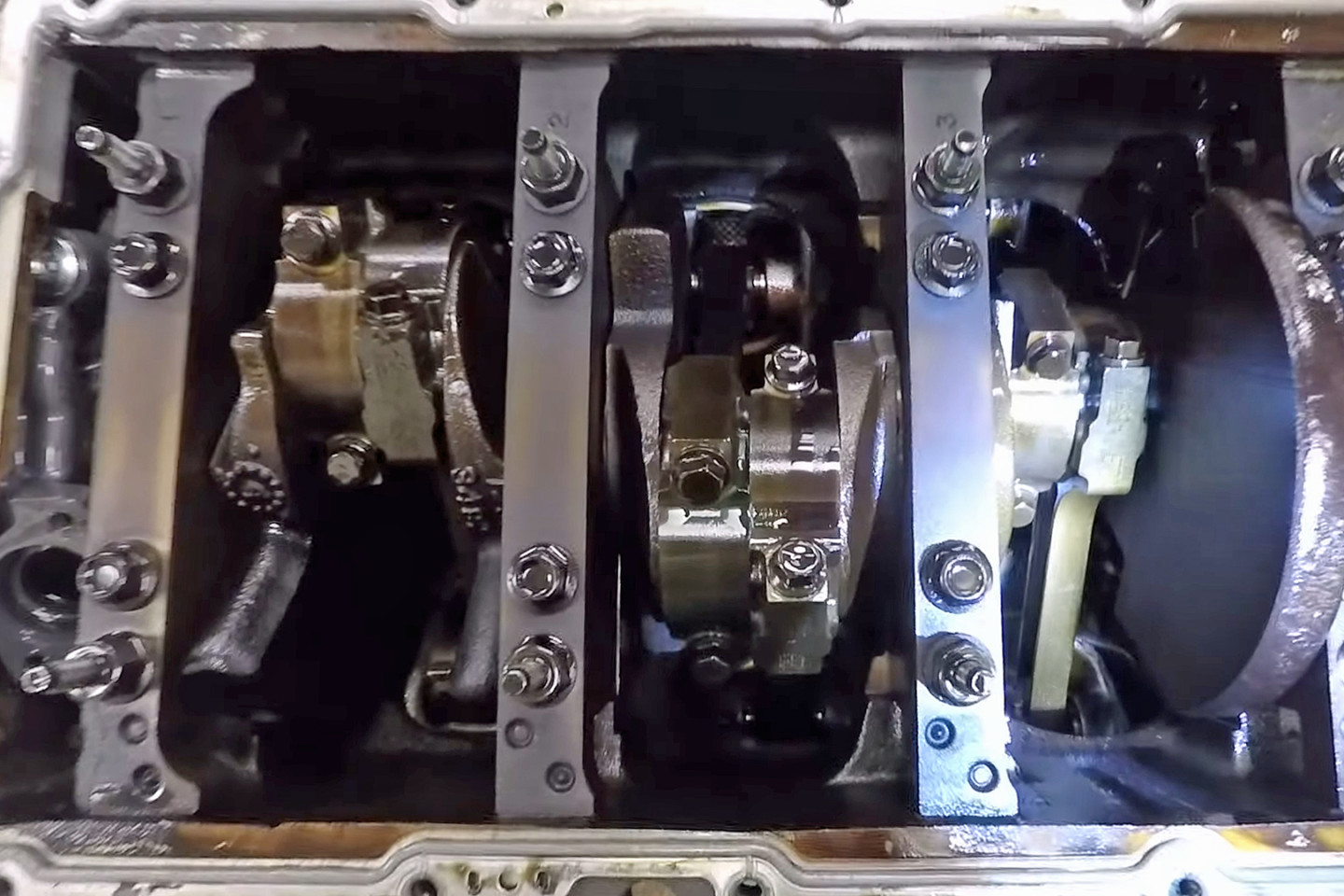

While there is no hard-and-fast definition of stock-bottom-end, there is absolutely no question that Roberts’ short-block meets even the strictest interpretation of the term. Starting with a 2005 4.8-liter LR4 long-block, Roberts pulled the heads and cam, and that’s it. With its 2005 build date, Roberts benefitted from having the upgraded Gen-IV factory crank, rods, and pistons. The short-block also has untouched main, rod, and camshaft bearings.

One area that seems to be on the gray side of things in the stock-bottom-end world, is the piston rings. It’s common practice to pull the stock piston rings and open up the gap to account for the massive amounts of boost being run. However, Roberts hasn’t even checked the factory ring gap. “The rings have been properly gapped by roughly 140,000 miles of driving,” he laughs.

He has upgraded the oil pump to a Melling 10296, which offers 18-percent more volume and 10-percent more pressure than the OEM pump, along with a cast-aluminum Holley LS Retro-Fit oil pan. “I’m currently switching to a Moroso fabricated pan to increase clearance with an engine diaper,” Roberts says.

There is no grey area in Robert’s short-block. Besides the factory Gen-IV crankshaft, rods, and pistons, the main, rod, and cam bearings are untouched, as well. It even has the factory ring gap on the factory piston rings in place. This rotating assembly is exactly how it left the plant in 2005.

Not So Stock Top End

For the cylinder heads, there wasn’t a whole lot of consideration put into the unmodified OEM 706 castings that came with the long-block. “I think a lot of people get too into getting the best flowing head they can, when a lot of times it isn’t necessary; especially boosted,” says Roberts. However, he is in the process of swapping to a set of Wilkes Performance-ported 862 castings.

“I am not sure how much power I will gain with the new heads. I think the biggest gain for me will be the better flowing head with bigger valves helping the engine make power at higher RPM. I imagine there will be some solid gains on the same boost level though,” explains Roberts. In addition to the improved ports, the new heads also feature significantly larger 2.02-inch intake valves and slightly larger 1.57-inch exhaust valves.

Controlling those valves at 8,000-plus RPM is no small feat. “The valvetrain is definitely one of the biggest parts of the combination. I had to spend some money in that area to keep the engine happy at the speeds it’s turning.” Roberts says. To keep the valves under control, a Brian Tooley Racing Ultimate RPM spring kit is used.

Advertised as capable of handling .685 inch of lift at the valve, the kit features dual valvesprings that measure 195 pounds of seat pressure and 480 pounds of open pressure. Additionally, the kit comes with locators for use with stock guides, locks, seals, and titanium retainers. Actuating the valves is a set of stock rocker arms that have been fitted with a Smith Brothers trunnion kit.

Previously, a cam spec’d by John Bewley (under the Little John Motor Sports banner), acted as the brain of the combination. But, recently Roberts switched it out for a new cam, also spec’d by Bewley (this time under the new Full Proof Performance name) and manufactured by COMP Cams. The old cam, used to set the record, features .601/.606 lift at the valve with 227/233 degrees of duration at .050 inch, with a 111-degree lobe separation angle. The new cam specs are being played a little closer to the vest, for now. A factory timing set is used, with an Iwis timing chain.

A set of Johnson short-travel, slow leak-down, race-style hydraulic roller lifters ride the cam lobes, while a set of Brian Tooley Racing 3/8-inch-diameter, .080-inch wall-thickness chromoloy pushrods translate cam motion to the rocker arms. Something to consider with Roberts’ valvetrain, is that he doesn’t just spin the engine to see a number on the tach, but to actually make power there, but we’ll discuss that more in-depth, later in the article.

This chassis dyno graph shows the combination making 1,141 horsepower and 850 lb-ft of torque — on only 30psi. If you run the math on his record-breaking pass, those numbers jump to 1,277 horsepower.

Force Feeding Four Atmospheres

Topping off the long-block is an Edelbrock Pro-Flo XT intake manifold fitted with a 92mm G-Plus throttle body, and a set of Bosch 210 lb/hr injectors fed by three Walbro 450 liter-per-hour pumps. Roberts’ fuel adventures started with straight E85, then a 50-50 mix of e85 and VP Racing Fuels C16, but encountered a wall with the fuel pumps’ capabilities.

Since the new combination will be run on straight methanol, Roberts has swapped to a Waterman Racing Mini-Bertha mechanical fuel pump with a Robert Ette pump drive and added an additional eight Bosch 210 injectors.

Surprisingly, the stock coils keep the fires lit on the combination, but, arguably, the bulk of the power comes courtesy of compressed atmosphere delivered to the intake. Previously, the combination consisted of a pair of BorgWarner S366 SX-E 66mm turbochargers.

However, Roberts has recently opted for a big single turbocharger, going with a Forced Inductions GTR-88 turbo with an 88mm billet compressor wheel and a 1.15 A/R ratio. A Holley Dominator controls everything, while a set of inexpensive eBay 1-3/4-inch primary to 2.5-inch-collector turbo manifolds handle all the exhaust gasses. So far, Roberts has seen a peak boost number of 41.1 psi.

“I figured that I would be pretty safe until I started getting over 30psi,” Roberts says. “When I broke the record the first time, I thought for sure I was putting the tuneup in it that was going to kill it. I ran 32psi in my thin New Mexico air, but I knew that was going to be nothing like 35-plus-psi in -700ft DA down in Houston. The last time out, when I reset the record again with the 7.80, I hit a peak of 41.1psi and somehow all the rods are still straight and inside the engine.”

Roberts' record-breaking performances were powered by twin BorgWarner S366 turbochargers fed by a pair of eBay special exhaust manifolds. In his latest quest to either reset the record or blow the engine up, he's switched to a Forced Inductions-modified GTR-88 with a billet compressor wheel.

What Witchcraft is This?

With an older engine dyno test showing 1,141 horsepower and 850 lb-ft of torque at 30psi, and 1,277 horsepower from a calculator using eighth-mile trap speed and race weight, it’s obvious Roberts is making serious steam, so we asked him for his secret. “I don’t think there is one single thing; it’s a combination of every single part that goes into it. GM gave us a very over-engineered product to start with though. I think everyone can agree with that,” says Roberts.

For an engine that started life naturally aspirated and making 265 horsepower, to now be living with over 40psi being crammed down its gullet, and making almost five times more power, is a Herculean feat. “The biggest factors, in my opinion, are the tune, converter, valvetrain, and chassis,” Roberts explains.

“With the tune wrong enough, you can blow a motor up at 300hp. I have spent most of my time researching and testing things on the tuning side to make sure that is as good as it can be. That is also part of why I started tuning and working on my own stuff. Nobody cares about your stuff more than you, and nobody wants you to be fast more than you do.”

Roberts' new heads are a set of Wilkes' Performance ported 862s, which feature a 227cc intake runner, 84cc exhaust runner, a 62cc combustion chamber and 2.02/1.57-inch valves. Roberts expects most of his gains to happen in high-RPM airflow.

While a spot-on tune is essential, it still can’t defy physics, and eventually, something will have to give. “I have yet to find that limit myself, either on customer cars or my own,” says Roberts. “But, from watching my good friend Jonathan Capizzi push a few to the limits, I believe keeping the heads from lifting may be the limiting factor, or possibly the rods.”

“I may end up finding something from RPM, though, as I plan to take the engine up to around the 9,000-rpm range. I plan to run this little 4.8 until it can’t run anymore. I have been planning my next motor since shortly after I started with the 4.8. I never expected it to get this far, so I have had plenty of time to plan that out. The goal is to be a killer in the stock-block classes that are starting to get popular. It will more than likely still be a small cubic inch, high-RPM combination.”

As Roberts continues his quest to reset the record and find the limits of the stock bottom end, he is documenting the whole journey on his Squirrel Tuned YouTube channel. Whether he finds that limit on the next pass, or in the next year, he has already accomplished a feat that almost no one expected – making this kind of power for an extended period — all on the factory block and rotating assembly, exactly as it came off of the assembly line 15 years ago.

In this video, you can see the realtime data from Roberts’ record-breaking 7.80 @ 168mph pass. Note the brief journey to 41.1psi of boost and peak RPM of 8,342 — from a stock 4.8L LR4 short-block, that has the same bearings and piston ring gaps as when it left the factory.