A business with a long history and dedication to quality American-made transmissions has flourished for over 60 years. Jim Beattie founded ATI Performance in 1961, and today JC Beattie, Jr., Jim’s son, is the company’s CEO, President, and Owner, is continuing his father’s legacy. The company is known for winning races and producing some of the best transmissions available. ATI’s tale exemplifies American ingenuity, tenacity, and innovation from its modest beginnings to becoming a market leader.

The roots of ATI can be traced back to a dream and an unrelenting individual, Jim Beattie. His dream to make superior auto parts was the driving force behind the company’s early success. Jim had an interest in both racing and engineering, and he set out to create innovations that would rattle the world of racing.

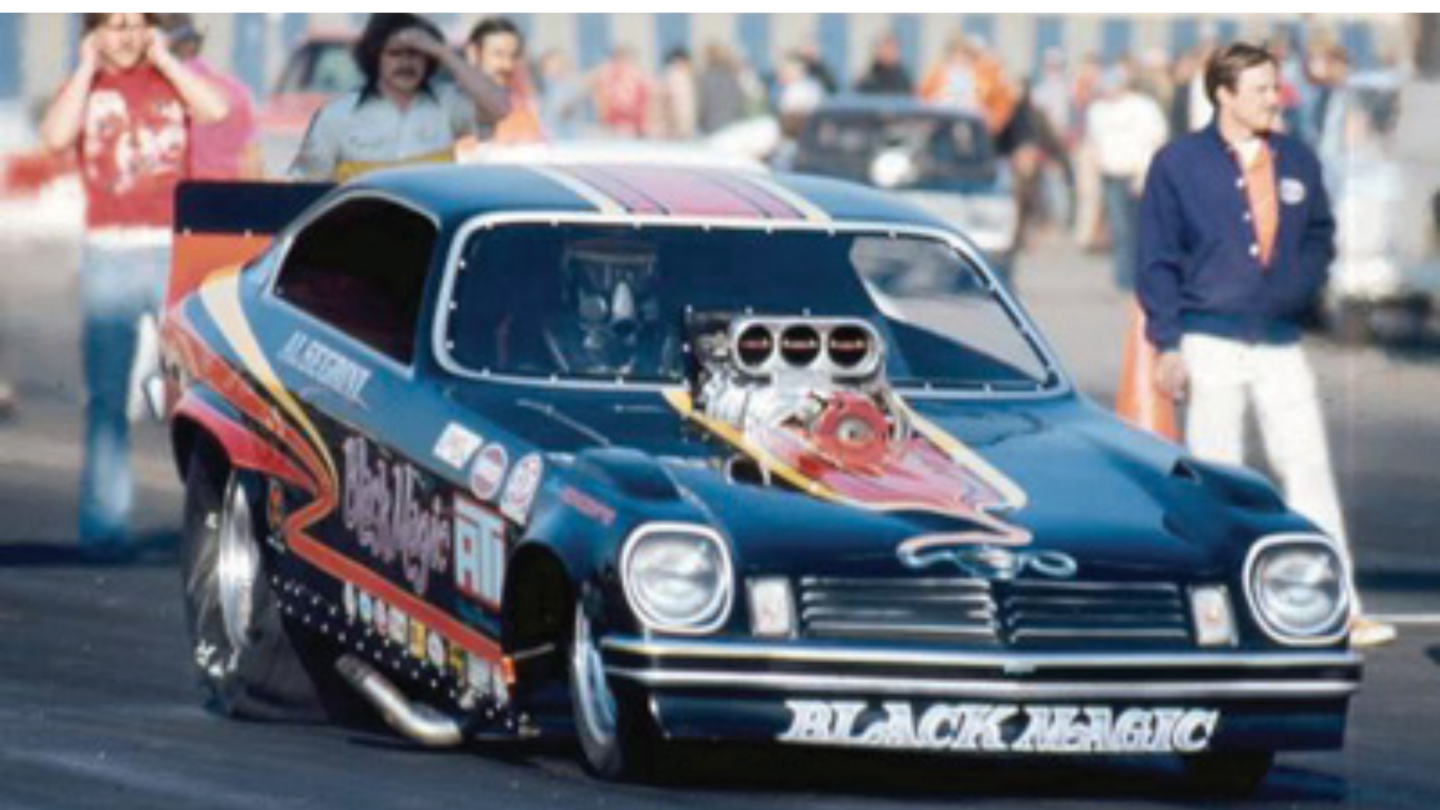

Al Segrini unveiled the ATI-sponsored Black Magic Funny Car in 1974. The car qualified seventh for the Gatornationals and clocked the third-lowest e.t. of the event during eliminations. It also won Best Appearing Car and Crew awards, a first in NHRA history for a single Funny Car team. Black Magic later won the Summernational in Englishtown, New Jersey, that same year.

Jim began his career in a modest workshop in Baltimore, Maryland, where he became known for producing high-quality transmission components and providing exceptional customer service. As word spread about ATI’s dedication to quality, its place in the automotive community was set in stone. Furthermore, ATI is not just a corporation; it’s a family affair. Jim Beattie’s legacy remains alive in the company’s core values, which guide its decisions and actions. JC’s mother is actively involved in the company’s operations. Her continued dedication is a testament to the deep-rooted commitment the Beattie family has to ATI’s employees and customers.

Despite Jim’s passing eight years ago, JC Beattie, Jr. has become a key figure in the company’s management. In 2003, JC completed his undergraduate studies and began working full-time for ATI. Jim’s legacy remains an inspiration to everyone within the organization, reminding them of the foundation on which the company was built. Under JC’s direction, ATI has continued to experience growth and technological advancement.

Whether it’s in his LS-powered Copo Camaro or one of the other ATI-backed racecars, JC Beattie, Jr. can be found most weekends in a race car at a drag strip.

ATI’s success in producing top-tier transmissions can be attributed to the company’s internal capabilities. The business maintains complete control over the manufacturing process thanks to its collection of 36 CNC machines. ATI believes that doing as much as possible in-house, from design to production, is the best way to ensure the highest quality and precision standards are met.

“The only things we don’t do in-house are castings, furnace brazing, centerless grinding, or forgings,” JC says, pointing out that all other aspects of R&D, testing, and production are performed at ATI’s facilities. With three full-time engineers, a dedicated programmer, and an in-house design team, ATI makes sure every part that has its name on it is made with care. In an industry where quality, dependability, and durability are paramount, ATI’s commitment to having experts on staff has changed the game. To ensure that customers get products that meet or exceed their expectations ATI maintains strict quality control by keeping a tight grip on the production processes.

JC Beattie, Jr. believes the best way to prove a new design is to put it into a car and give it real-world abuse. He races multiple cars to verify the products his company sells all work as advertised.

The daily challenges of maintaining a wholly American production operation can be an ever-evolving landscape. Although the cost of doing business in the United States is high compared to abroad, ATI perseveres because of its dedication to producing high-quality goods. Sourcing American-made steel bar stock, essential to ATI’s manufacturing processes, is one of the biggest challenges. Regardless, ATI continues to support American businesses and uphold the “Made in America” tradition.

Through its actions, ATI proudly serves as a safeguard of American manufacturing in a time when outsourcing and offshore production are commonplace. The term “American-made” is more than just a slogan or motto. It’s a value dear to JC and all the ATI employees. While he acknowledges that it has continually become more expensive to do business in America, JC remains aware of the importance of keeping jobs and production in the United States. So despite the rising costs of things like labor and raw materials, ATI is unwavering in its commitment to upholding the traditions of American manufacturing.

Alex Laughlin wins the 2020 Pro Mod class at the Doorslammer Nationals at Orlando while driving the ATI Performance Products’ backed Caruso Family Pro Mod Camaro.

ATI’s success lies not only in its quality but also in its ability to diversify its product offerings. Rather than placing all its eggs in one basket, the company wisely divides its business into two core segments: automatic transmissions and dampers. ATI also carries other various transmission-related parts, so be sure to check them out for all your transmission needs.

Racers and performance enthusiasts looking to maximize engine efficiency and minimize vibrations are drawn to ATI’s dampers. The transmissions and converters division provides state-of-the-art solutions to handle the high power and torque requirements of racing and high-performance vehicles. Due to ATI’s experience in this field, numerous championship-winning alliances have been formed with racers worldwide. A wide variety of additional parts are also offered by ATI, such as slip yokes, shifters, and transmission coolers.

Continuous innovation and a commitment to quality go hand-in-hand. ATI makes R&D investments to keep its products at the forefront of technological development, and it has multiple race cars, including a Pro Mod and a COPO Camaro, that are used in competition to test and improve its products. Priceless information and feedback can be gathered from using its products in real-world racing situations. This information is then used to enhance and further fine-tune ATI’s product line, ensuring that it continues to be a leader in the automotive industry.

JC Beattie, Jr. races multiple cars in a variety of classes including this ATI-sponsored Dodge Challenger in the Stock Eliminator division.

In addition to on-track testing and product development, every transmission that leaves ATI has been painstakingly tested and run on its in-house transmission dyno. Thanks to quality assurance procedures, every transmission adheres to the high-performance standards for which ATI is renowned.

As it looks to the future, ATI welcomes the opportunities and challenges that lie ahead. The company is currently retooling to add new Powerglide and TH400 cases to its product lineup. They recently unveiled new bellhousings and dampers, as well, demonstrating their dedication to staying at the forefront of innovation. ATI is well-positioned to carry on its legacy of success thanks to its constantly expanding team of knowledgeable professionals. The company’s dedication to quality, in-house know-how, and American manufacturing is proof of the principles that have guided them for more than 60 years.