If you’ve ever rebuilt an LS engine (among others) you’ve encountered a specification called torque angle. Put into its most simple terms, torque angle replaces a maximum torque value for a fastener with a specific amount of fastener rotation. After setting a low baseline torque, just to make sure the fastener is set, the fastener is rotated a precise amount to set the final position and clamp load.

If all you care about is following the manual and moving on, watch the above video from Summit Racing, and you’re good to go. However, if you’re at all curious as to what is actually happening, and why the torque angle measurement has become more and more common in service manuals across the industry, then read on.

Why Torque Angle?

First, we need to clear up a common misconception before going forward. While many torque-to-yield fasteners used by OEMs call for a torque angle measurement, the process isn’t specific to a T-T-Y fastener. It is, however, an amazingly accurate way to stretch a bolt a specific amount, which is absolutely critical in a torque-to-yield fastener.

Since we’re going back to basics, let’s cover the basic purpose of a fastener. A bolt is used to hold two objects together. In automotive applications, there are often specifications for how tightly you want the two specific parts held together. Too tight and you risk damaging the parts or the fastener itself. Too loose, and there isn’t enough clamp load and the two parts can leak or shift under load.

The amount of clamp load (how much the fastener “squeezes” the two objects it’s joining) is determined by the fastener’s diameter, material, and how much the fastener is stretching. Since we can’t measure the actual stretch of a bolt (save for rod bolts, discussed in the linked article below) we need to find another way to measure bolt stretch.

For a lot of years, the automotive industry has used torque values to be that yardstick. The thought process being, by calculating the amount of resistance to rotation, it could be determined how much force was being exerted on the threads. While that is still a highly effective method of determining clamp load, there can be some drawbacks and inconsistencies with the method.

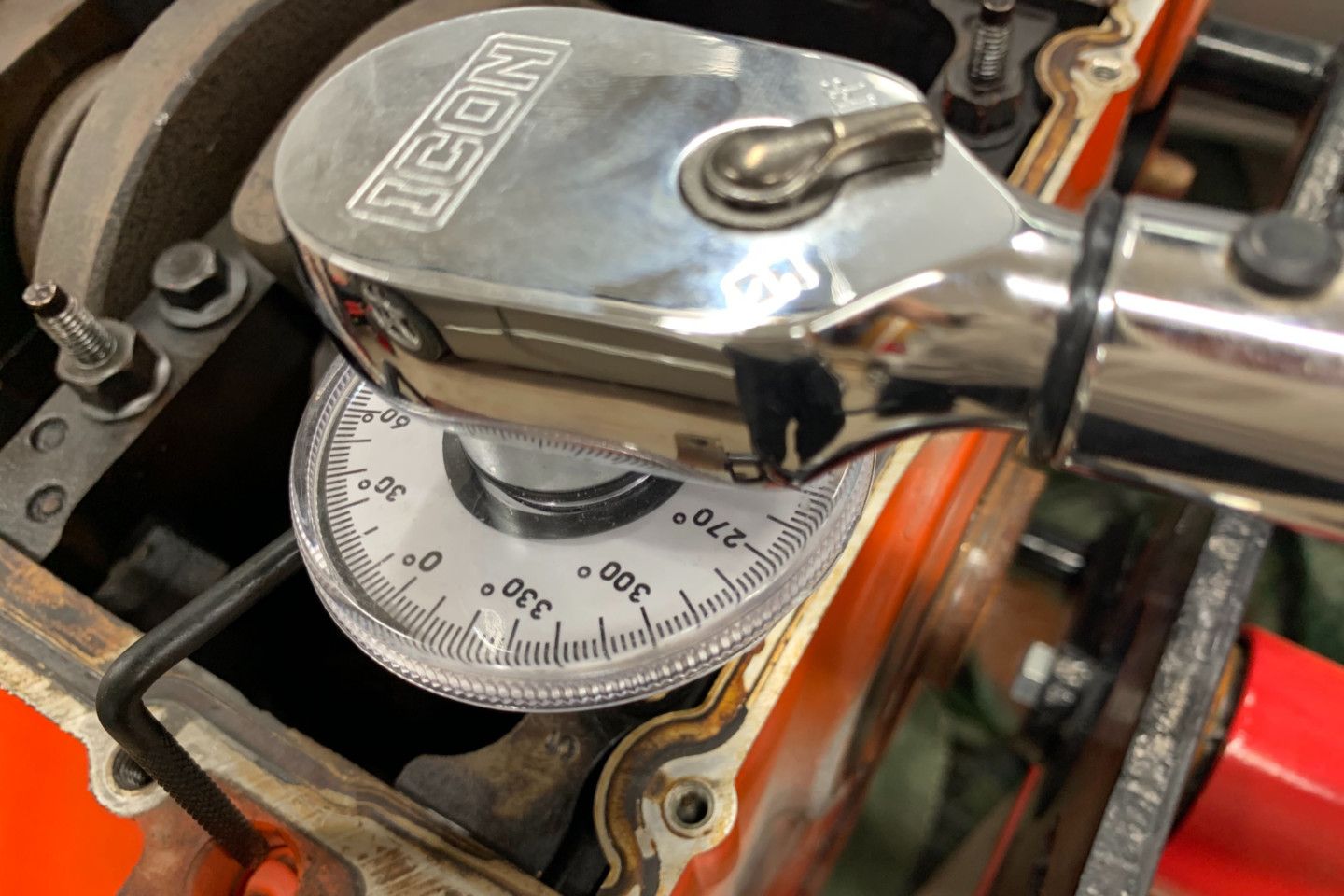

Here you can see an inexpensive torque angle gauge being used. The leg off to the left holds the body in place, while the square drive section moves the pointer as the wrench is turned.

In previous articles (like this one and this one) we’ve discussed some of the intricacies of fastener torque. While you can get lost in the weeds with those, they do illustrate some of the issues with using a fastener’s resistance to motion as a measure of its stretch.

Even though there are “dry” and “wet” torque values to take into account the absence or presence of thread lubrication, as well as thread lubricants from companies like ARP designed specifically to combat the drawbacks of dry threads, or threads using 30w motor oil, the fact is there are a large number of variables that come into play with the external torque method. Enter modern engineers who needed a more precise way to ensure an exact amount of fastener stretch.

How Torque Angle Works

To explain how torque angle works, we need to work backward. Engineers first determine the desired clamp load for the items. Once they know that, they can run the numbers based on fastener size and material to determine the required bolt stretch to achieve that clamp load. From there, it’s simply a matter of taking the thread pitch of the fastener and determining how many degrees of rotation are required for the fastener to be stretched the desired amount.

While it seems complicated, the reality is that all of the big-brain calculations are done by the engineers of the application ahead of time. All you have to do is be able to accurately set the first-stage torque (which is usually relatively low, in order to be able to better withstand any variations in conditions) and then properly measure rotation from that point forward.

To accomplish that, there are tools at both ends of the price spectrum, ranging from home-made templates crafted with a protractor, marker, and paper, to inexpensive dial-gauges that fit between your ratchet and socket, all the way up to digital torque wrenches with built-in angle gauges.

Will we see torque angle measurements take over the automotive industry? Probably not any time soon. However torque angle specifications are becoming more and more prevalent, so understanding and knowing how to properly use them will be a valuable skill in your mental toolbox.

Threads of an SAE fastener are measured in threads-per-inch. Let’s assume this was a fine-thread 3/8-inch-diameter bolt. That would mean there are 24 threads-per-inch. If we divide one by the TPI count, we get the amount of distance the bolt travels in one rotation (.0416 inch). If the engineers calculated that they wanted, say, 0.010-inch of bolt stretch beyond whatever is induced by the 15 lb-ft baseline, the math calculates out to 86.4 degrees of torque angle.