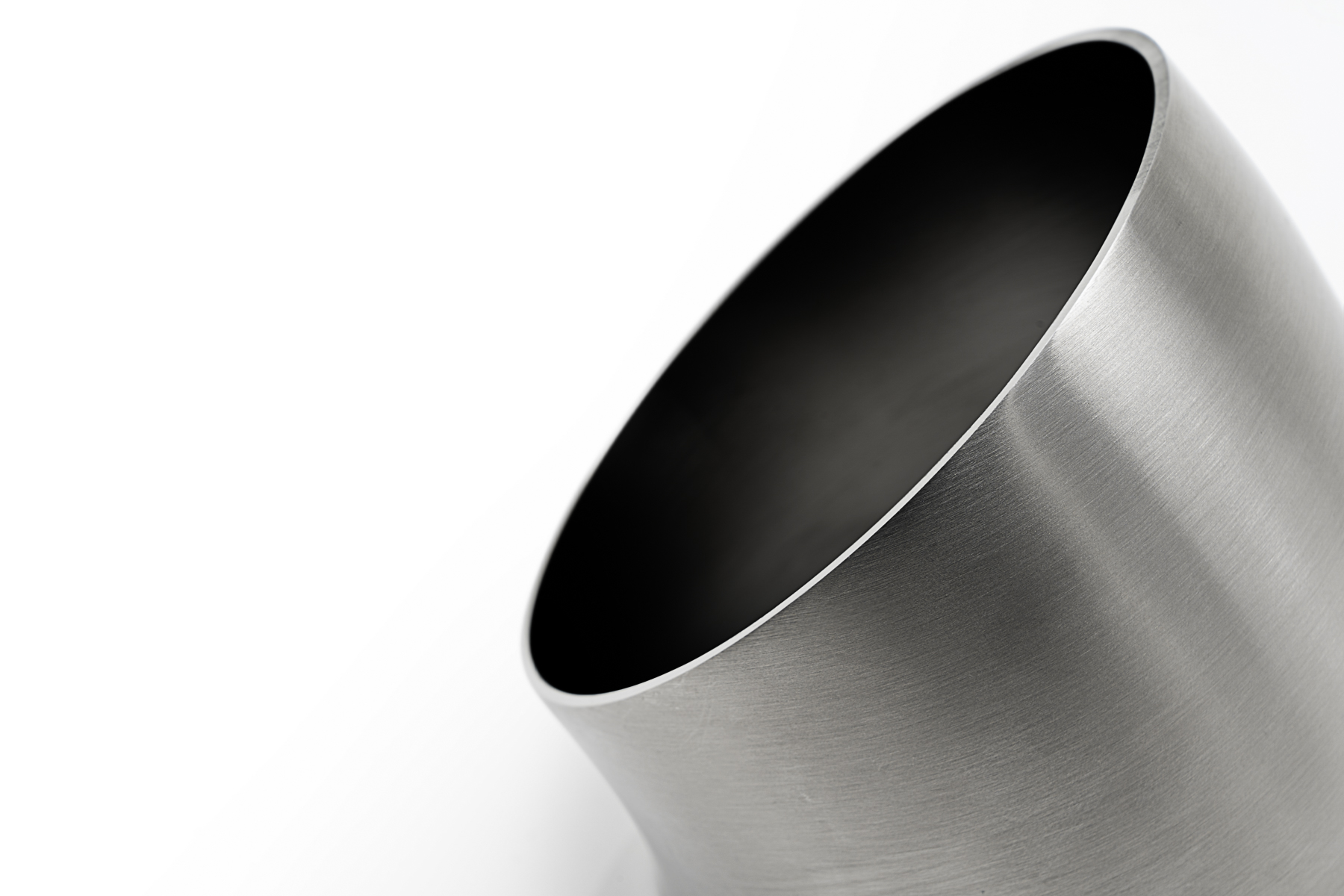

Fabricating exhaust parts is time-consuming. You have to figure out the design of the parts, prep the material, and then weld everything together after you’ve confirmed it fits. Vibrant Performance’s 304 Stainless Steel Brushed Bends will cut down on your material prep time, and allow fabricators to finish a project quicker.

These bends require little to no prep work, so you can use them as they come out of the box. The Brushed Bends that Vibrant have developed are both scratch and corrosion-resistant, which allows them to last a long time. Vibrant offers these Brushed Bends in 1-1/2” to 4” O.D. sizes. You can choose from either 90 or 45-degree right radius (1D) bends.

The 304 Stainless Steel Brushed Bends can be used to make headers, turbocharger exhaust systems, induction systems, and other parts. Vibrant’s short leg lengths help to reduce the amount of material that’s wasted when fabricating parts.

Kyle Hyatali from Vibrant Performance explains why these bends are a great choice for any project.

“Brushed bends are a great option for any application where aesthetics is a priority. These bends are an excellent choice because they transform the appearance of typical welded assemblies into showpieces. Instead of performing the additional step of brushing your pieces before you weld, you can now buy brushed bends that are ready to weld right out of the box with a beautiful and consistent finish.”

You can learn more about these Vibrant Performance 304 Stainless Steel Brushed Bends right here on the company’s website.