The day is almost upon us. LS Fest East is quickly approaching, as is our nine-day deadline, and we are working diligently towards firing up Project 899 for the first time. If we are to succeed in meeting our goals, not only do we need to have the car completed in nine days, but we also need to tune it before loading the Camaro up and heading to LS Fest East in Bowling Green, Kentucky.

To bring Project 899 to life we need to complete several things on our list. Namely, the wiring has to be finished for the car to have any chance of starting. While Chuck wired up the fuel pump, starter, radiator fans, and a few other things, Jeremy, Bob, and Rick focused on finishing everything under the hood.

?si=zCGW3QmoH7kwRpXe

Our Camaro needs fluids, and for that to happen, we needed to make several hoses to get coolant and oils where they needed to go. We used Earl’s Performance components that we sourced through Summit Racing for all of the fluid transfer duties. For oil lines, we used Earl’s Pro-Lite 350 nylon-braided hose and black hose ends. This combination is rated to handle 350 psi, making it an excellent choice for various oils, and its all-black looks go well with the rest of our engine bay. To get the E85 fuel from the cell up to the regulator and the fuel rails, we ran Earl’s UltraPro hose, which has a PTFE inner liner, making it perfect for the fuel we’re running. For the initial start-up in the car, we chose to use Driven Racing Oil‘s BR30 Break-In Oil. It’s a high-quality 5W-30 oil that Driven has engineered specifically for high-performance engines.

Bob filled the L8T with Driven Racing Oil's BR30 break-in oil for the initial start-up in the car while Rick filled the ATI TH400 with ATI's high-performance transmission fluid.

Supplying fuel to our LME-built Whipple-supercharged L8T is all Aeromotive components. We started with a fuel cell and fuel pump package featuring Aeromotive’s 5.0 GPM Brushless Gear Pump, a built-in fuel level sending unit, a rollover valve, and an -8 AN return fitting welded into the fuel cell for connecting a bypass from the regulator. The regulator is an Extreme Flow EFI return-style, and we installed a flex fuel sensor in case we ever need to run the car on gasoline. Our injectors from Fuel Injector Clinic also arrived, so we buttoned up the fuel system and moved on to other areas of the car.

Two areas that needed Rick’s fabrication skills were the exhaust and the air intake. Beginning with the exhaust, he welded up a nice-looking system using parts of the Hooker Blackheart stainless steel 3-inch X-pipe kit we ordered along with a few universal bends to get it all installed where he wanted it. Rick then welded a couple of V-bands to make the connection to the headers which will make removing the entire exhaust system a quick and easy task. He also mounted the Blackheart mufflers just in front of the rear axle with turn-downs so that nothing would interfere with the antiroll bar. With the exhaust complete, we could install the Strange Engineering driveshaft, and Rick could move on to fabricating the air intake tube and throttle cable bracket.

Rick made installing the exhaust system look like child's play.

To get the car sitting on its own feet so we could set ride height and take measurements for installing the antiroll bar, Jeremy mounted the rear wheels and tires. We chose to run RC Components‘ new Torx Heathen single-beadlock rear wheels that are 15×9 and the Torx Front Race wheels that measure 17×4.5. Handling the steering duties are Mickey Thompson 26.0/4.0-17 ET Front tires. Meanwhile, out back, Mickey Thompson P275/60R15 ET Street Radial Pro tires will give us all the hook we need.

The Torx series wheels from RC Components matched with Mickey Thompson tires are a great combination for Project 899 to look great and perform on the drag strip.

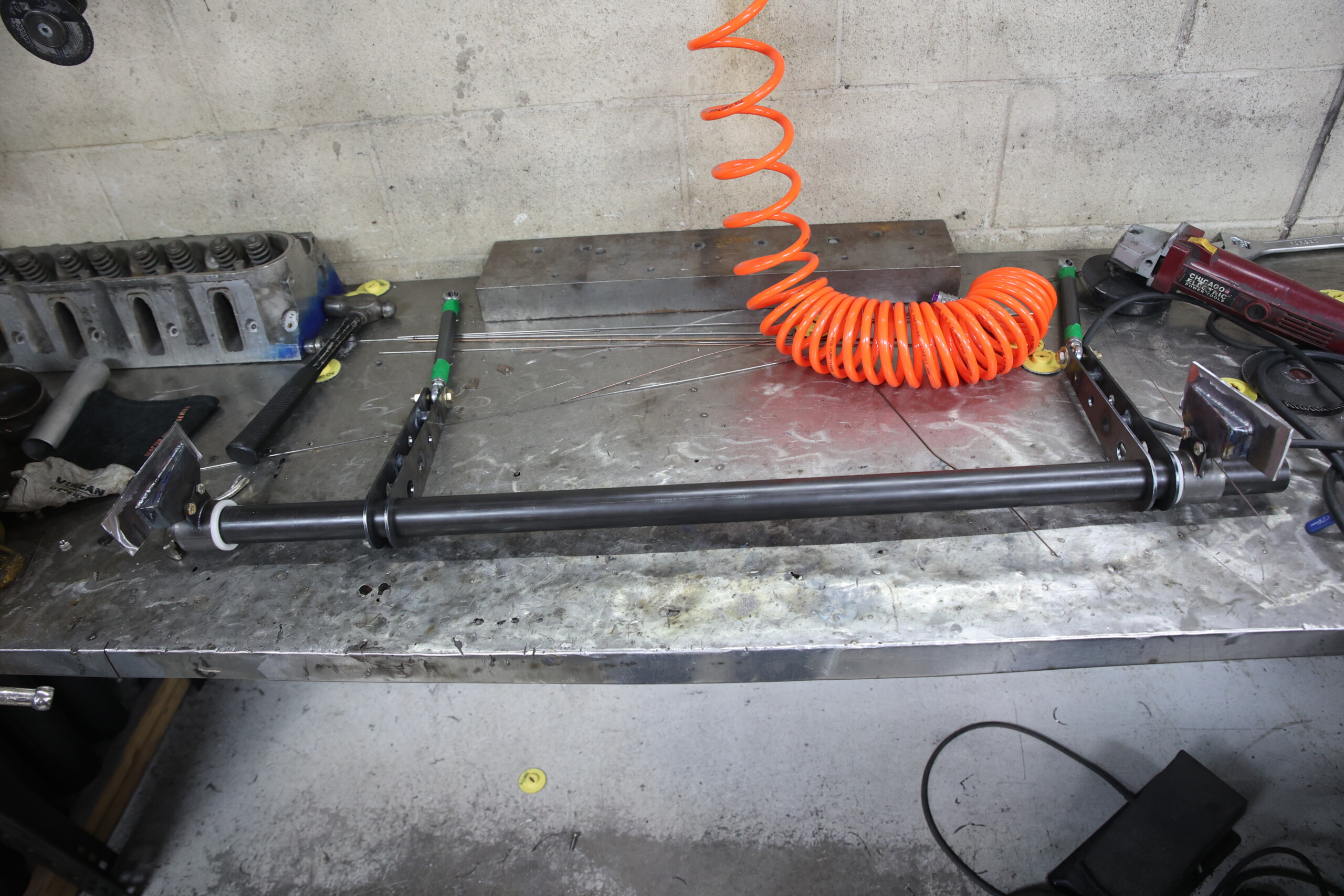

By the time day six rolled around, we could see the finish line of completing Project 899, and we were all anxious to get things buttoned up, get a tune in the car, and hear it fire up for the first time. We still needed to make several hoses and get them installed, and the last major component to finish was the anti-roll bar. Because of how the ’69 Camaro frame rails are shaped, Chuck and Rick needed to measure and fabricate offset mounting plates to ensure the anti-roll bar would mount square to the car’s chassis.

By taking several measurements Rick was able to fabricate these offset mounting brackets that were then welded to the frame rails. This ensures the anti-roll bar is square to the chassis and will operate as intended.

Finally, we were ready for the moment we had been working towards for the last week. Rick loaded a base tune into the Holley Dominator system and gave the starter button a push. With relative ease, the L8T roared to life. I’m happy to say Project 899 sounds like a hot rod should sound. The tone from the Blackheart X-pipe and mufflers is deep and the whine from the Whipple supercharger is music to the ears. Seeing the Camaro sitting on the ground idling and ready to move under its own power was an exciting moment.

What our team was able to accomplish in a week overcoming obstacles and parts delays is impressive. Now we just have to dial in the tune on the chassis dyno and see if we make more than 899 wheel-horsepower. Of course, we’ll be showing you all of the dyno testing soon. We couldn’t be more excited to see what Project 899 is capable of and we’re thrilled to bring the Camaro to show all of you at LS Fest East. If you see us and the car at the event be sure to come check it out up close and ask any questions you have.