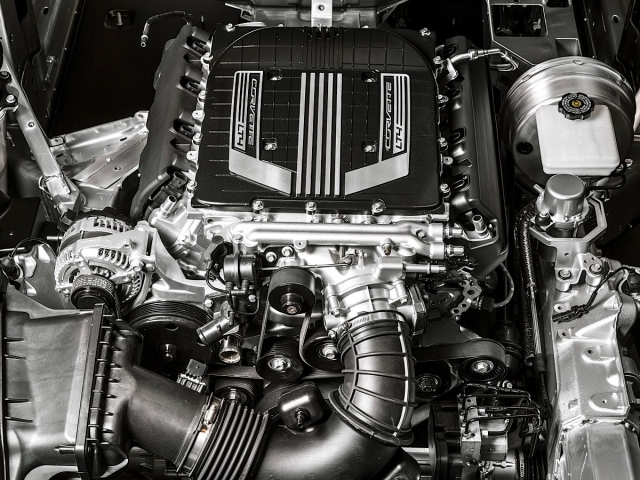

The 2015 Corvette Z06 features an all-new LT4 engine. The supercharged, 6.2L V-8 will deliver more than 625 horsepower, and 635 lb-ft of torque.

The estimated 625-horsepower figure quoted for Chevy’s new 6.2-liter supercharged LT4 at the Detroit Auto Show unveiling of the upcoming 2015 Corvette Z06 is likely to spiral upwards when the final production model hits the dealerships early next year, according to the engine’s chief engineer.

“We fully expect to beat that number, but we came up with a safe estimate for the show,” boasts Jordan Lee, program manager for GM’s small-block program, also noting that the estimated 634 lb-ft of peak torque should escalate, as well.

The LT4 not only sports a new Eaton supercharger model, but nearly every standard Corvette LT1 engine component was modified, massaged or updated to support the power and packaging goals of the LT4 powertrain team.

“The challenge for us was to add 160-plus horsepower but not get any bigger [than the LT1],” Lee tells EngineLabs. “As remarkable as the LT1 is in power density, the LT4 beats it in droves.”

The LT1, of course, is first of the Gen V small-block engines to hit the market in the new C7 Corvette platform. As EngineLabs demonstrated in previous stories covering the engine’s introduction and an in-depth analysis of the combustion strategy, the LT1 is one of the smallest and most compact engines in the world that is capable of 460 horsepower naturally aspirated. GM wanted to ensure that the engine package didn’t inflate so the Corvette could be offered for sale in Europe.

“We ended up about an inch taller only in the back where the supercharger has an airflow path into the intercooler,” says Lee.

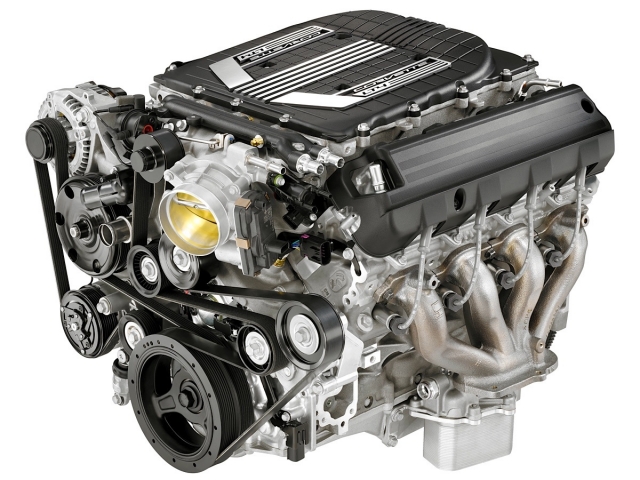

Key to the success of adding boost was working with airflow analysis and development engineers at Eaton to improve the supercharger’s efficiency, even though the blower is smaller than what GM utilized on the Gen IV LS9 engine found in the previous C6 Corvette ZR1. That 6.2-liter engine was rated at 638 horsepower at 6,500 rpm with 604 lb-ft peak torque at a stump-pulling 3,800 rpm.

“The LT4 supercharger is 85mm shorter in height than the one on the LS9, and it weighs 20 pounds less,” says Lee.

Eaton rates the new R1740 TVS supercharger at 1.7-liter, which means it moves that much air with each revolution of the rotors. The previous LS9 supercharger was rated at 2.3-liter.

“We shrunk the capacity down to 1.74 liter,” says Lee, “but we wanted the same airflow characteristics. So we had to spin the supercharger faster.”

The LT4 will weigh close to the LS9 engine, left photo, that powered the previous-generation Corvette ZR1. That engine used a larger 2.3-liter Eaton supercharger, shown on the right.

“We worked a lot of the efficiencies through the supercharger to make sure the airflow was up to the quantity levels needed to make the power,” says Lee.

As with the LS9, there is an air-to-water intercooler integrated into the cast-aluminum intake manifold. But unlike the LS9, the new setup features a clamshell core design with turbolator fins inside the water path compared to a traditional tube with aluminum vanes for the core.

The Eaton twin-vortices TVS superchargers are designed with unique 4-lobe, Roots-style positive-displacement style rotors that feature a 160-degree helical twist for improved efficiency with less noise. They will be spinning up to 20,000 rpm on the 1.7-liter version found on the LT4 engine.

“It’s a very efficient intercooler,” says Lee. “It’s about 23 percent less volume but has 10 percent improvement in heat-rejection efficiency. It’s probably not thee inches long in length but reduces the temperature of the inlet charge by 150 degrees.”

Adding more air requires additional fuel. The Gen V engines feature direction injection with high-pressure feeds coming from a cam-driven fuel pump.

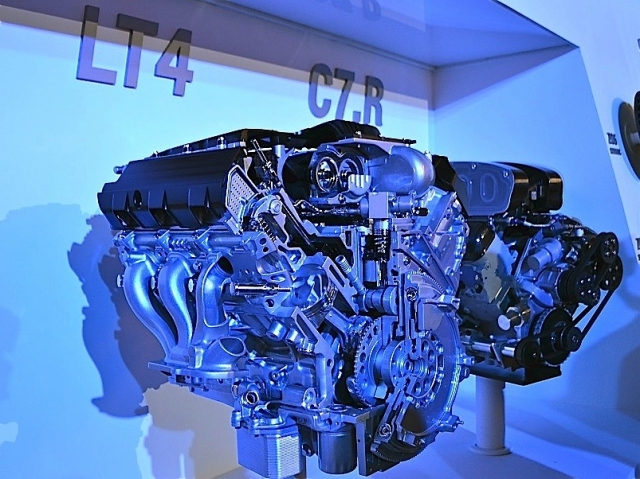

A cutaway of the new LT4 was on display at the Detroit Auto Show where the Z06 announcement was made. It’s shown next to a mockup of the 5.5-liter Gen V engine that powers the next C7.R race Corvette.

“The biggest challenge was the fuel pump itself,” explains Lee, noting that other exotic DOHC powerplants have up to four pumps to serve the fuel system. “With only one pump we had to increase the size and displacement to handle 625-plus horsepower worth of fuel.”

GM increased the piston size in the pump but didn’t have to change the tri-lobe cam design that drives the pump. Fuel pressure in the lines was increased — the LT1 fuel system operates at nearly 2,200 psi, but no figures were given for the LT4 — and the cylinder heads received larger injectors. The LT1 cylinder ports didn’t need any additional breathing room, but a lighter titanium intake valve was preferred, and the LT1 cast piston was swapped for a forged version that offers a lower 10:1 compression ratio (the LT1 was 11.5:1).

“The 10:1 is till relatively high for a boosted engine,” says Lee, adding that max boost levels will be around 9.5 psi. “We also optimized the camshaft to get the torque and power curves we wanted. The lobe centerline spacing and lift profile are a little different from the LT1.”

The LS9 was also equipped with titanium intake valves as well as titanium connecting rods.

“We didn’t need titanium connecting rods to get the balance we required on the LT4,” counters Lee.

The LT4 features dry-sump oiling, and the oil cooler has been enlarged over the standard Z51 option setup.

In addition to the forged pistons, GM did beef up the entire rotating assembly. The crank is forged with a higher strength steel alloy than the LT1, and the connecting rods are fully machined.

“We added a lot of extra machining on the flanks for light weight,” says Lee. “Also, we annodized the lands on the piston and went with a PVD-coated ring. Finally, the piston pin has DLC coating to handle the extra temperature and pressure.”

Additional durability measures include constructing the cylinder heads with Rotocast A356T6 aluminum and casting the exhaust manifolds out of stainless steel.

Overall, the engine weight will come close to the LS9.

“The 20-pound decrease in the weight from the supercharger offsets the weight from the additional technologies like the DI pump, the cam phaser and AFM. We’ll end up with an estimate round 240 kilograms (529 pounds), which is where the LS9 came in.”

Finally, GM officials refused to speculate on the future availability of an LT4 crate engine when reminded that the LS9 eventually became part of the Chevy Performance catalog. But Lee does offer a reassuring hint: “We pride ourselves on making the small-block available to the aftermarket.”