Like the LS engine itself, the Eaton TVS 2300 supercharger rotor pack has become a worldwide favorite. You’ll find it in the factory superchargers for the late, great Corvette ZR1, as well as countless different aftermarket superchargers. The four-lobe design with a 160 degree twist gained its popularity thanks to its very high efficiency – always an issue for Roots-style positive displacement superchargers. Able to move a lot of air without making a lot of heat, it can be found at the heart of many popular blower systems.

Like the LS engine itself, the Eaton TVS 2300 supercharger rotor pack has become a worldwide favorite. You’ll find it in the factory superchargers for the late, great Corvette ZR1, as well as countless different aftermarket superchargers. The four-lobe design with a 160 degree twist gained its popularity thanks to its very high efficiency – always an issue for Roots-style positive displacement superchargers. Able to move a lot of air without making a lot of heat, it can be found at the heart of many popular blower systems.

But one of the most interesting things about the TVS 2300 rotor pack is that Eaton delivers it as just that; a bare pair of rotors, around which manufacturers are free to design their own housings, manifolds, drive setup, and everything else needed to produce a complete supercharger system. That’s led to a wide spectrum of different designs, most of which (at least in the aftermarket) have been fairly conservative and straightforward implementations of the Quick Start Guide to Twin Rotor Supercharging.

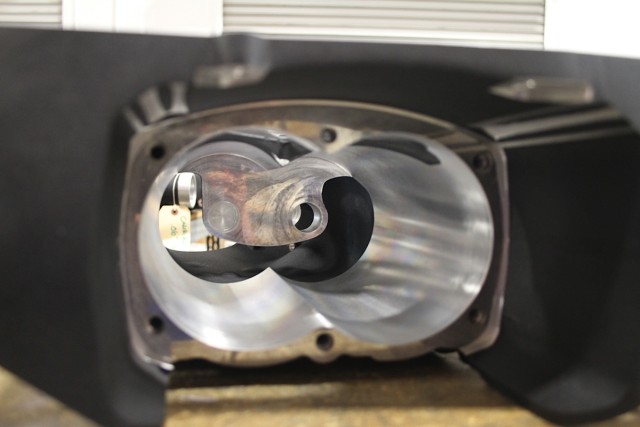

The future home of an Eaton TVS 2300 rotor pack. Each supercharger manufacturer that uses the TVS rotors builds their own housing, including GM.

While employing a “downdraft” design that exits the blower case at the bottom into an intercooler core, and from then into the individual cylinder runners is the simplest way to package all the needed components of a supercharger kit, it makes for a tall blower assembly that’s a tough fit under factory hoods. That’s one reason why General Motors went with an “updraft” design and dual intercoolers on the factory-supercharged LS9, and on the new LS4.

A New Generation

The Heartbeat was a departure for us in a lot of ways – how we design superchargers, build them, and bring them to market. – Matt Hately, Magnuson

The first question we asked was where the name came from – their previous systems have had very ‘practical’ names that were more descriptive than evocative. “The Heartbeat was a departure for us in a lot of ways – how we design superchargers, build them, and bring them to market,” Hately explains. “We wanted to give the Heartbeat a more emotional, meaningful name, and connect it back to the Chevy heritage, and allude to excitement and adrenaline (as in, gets your blood pumping). What’s funny is Australia is almost 50% of our market for the Heartbeat, but the name means something completely different. They obviously didn’t have the “Heartbeat of America” campaign down-under. Magnuson Australia uses “Get your Heartbeat racing” in their ads, and it definitely resonates with the Holden guys.”

Rather than using a jackshaft to carry power to the back of the blower case like previous Magnuson superchargers, the Heartbeat uses a front-drive system. Note how much belt wrap there is on this Camaro supercharger.

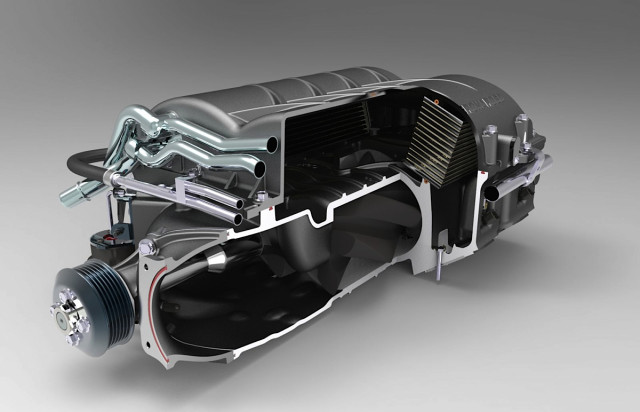

In their previous systems for these cars, the supercharger was driven from the back side via a jackshaft, and the entire blower housing sat atop the intercooler core. While that arrangement works well, and has plenty of satisfied customers, Magnuson made the commitment to spend the resources on developing a new generation of TVS-based superchargers with a very different layout. Like the GM factory Corvette blowers, the Heartbeat is driven directly from the front, exhausts upward, and features split intercooler cores to help reduce package height.

“Traditionally, our superchargers have been a top-mount, downwards discharge, meaning the supercharger blows downwards into a manifold,” Hately continues. “Many of our kits, including our GM Truck and Mopar HEMI kits are still this way. If there is hood clearance, they are efficient, cost-effective, and work great for the majority of applications and customers. When we set out to design the Heartbeat, our goal was to build a supercharger that fit under the Corvette C6 hood.”

Here’s a look at the LT4’s supercharger and intercoolers – note that the cores are in a ‘downdraft’ arrangement, and have to share space between the valve covers with the blower case itself.

Though they couldn’t have known it at the time, Magnuson’s engineers settled on a layout that splits the difference between the way GM designed the LS9 (dual side-draft intercoolers, still located entirely on top of the blower case) and the setup on the Gen V LT4 (“downdraft” intercoolers on either side of the blower case, very close to the intake ports). The Heartbeat puts its angled intercoolers mid-way between the blower outlet and the cylinder heads, trading a bit of extra height compared to the LT4 in exchange for more plenum volume, and room for bigger rotors.

One of the constraining factors in the LT4’s supercharger design was the need to absolutely minimize height, and in order to accomplish that and still have acceptably large heat exchangers tucked into the available space between the valve covers, the designers went with a TVS rotor pack displacing 1.7 liters instead of the 2.3 liters moved each revolution by the LT9’s blower. The LT4’s supercharger rotors are both shorter (7.9 inches compared to 8.3 inches) and smaller in diameter (3.9 inches vs. 4.4 inches), making more room for those intercoolers. To compensate for the lost displacement, the LT4 blower is driven 3.10 times crank speed, compared to 2.32:1 for the LS9.

Here's the Camaro Heartbeat system installed on their in-house development car. You can see that the blower case clears the factory strut bar, and there's room up front to accomodate the 2014-up hood insert.

Magnuson managed to pull off having their cake and eating it too – the Heartbeat packs the 2.3-liter TVS rotors, but will still fit without an aftermarket hood. “The Corvette Heartbeat is 1 7/8-inch taller than a stock LS3 manifold, so it fits under the hood of a C6 Corvette,” Hately points out. “On the Camaro LS3 and the ZL1/CTS-V LSA, we have a bit more hood clearance, so we can use a little taller lid, mostly for aesthetics and to get a bit more intercooler area. The Camaro unit not only fits under the factory strut-brace, but also under the new [2014] Camaro hood vent insert.”

Per Hately, “For a Corvette owner, that was one of the biggest deterrents to installing a supercharger – they didn’t want to have to replace their hood and try and paint match it. As we started designing it, we decided that since it would have to be a clean-sheet design, we may as well go all out, and build the next-generation Magnuson supercharger.”

More than Just Packaging

The Heartbeat supercharger family offers more than just space-saving advantages, though. The LS3 Corvette version is a full 17 pounds lighter than Magnuson’s previous “modular” TVS 2300 kit, and in back to back testing, they claim it made an additional 25 horsepower to the wheels compared to their other system. That can be attributed to a combination of better internal aerodynamics in the Heartbeat blower case, as well as the Formula 1-derived heat exchanger technology used in the intercooler cores.

In this cutaway, you can see the front air inlet, top exhaust from the rotor pack, and split dual intercooler cores.

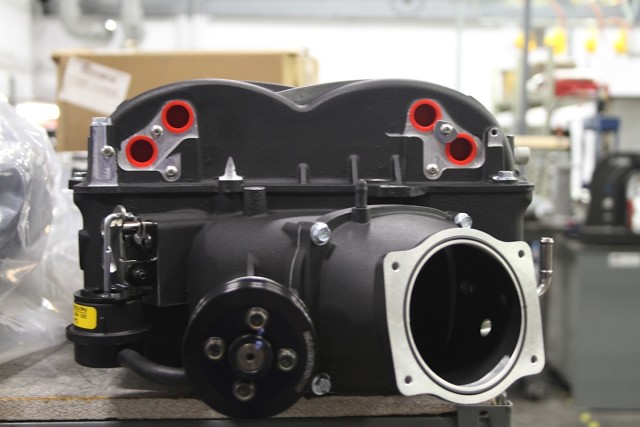

“One of the key things we were able to do is open up the intake,” Hately adds. “Superchargers will take almost all the air you can give them, and they respond well to things like larger throttle bodies and free-flowing intakes. On the Heartbeat, the air doesn’t have to go up and over the bypass port, and we have a straight shot into the rotors. We were also able to open up the frontal area of the intake – we can fit up to a 108 mm throttle-body with the right adapter. It made a huge difference in efficiency. We can make the same power, but on 2-3 fewer pounds of boost. That’s easier on the motor, and easier to keep cool.”

Many owners of factory-supercharged LSA and LS9 engines have found power increases by porting the stock inlet; per Hately, that advantage is baked right in to the Heartbeat supercharger. “If you want to get a sense for just how open the intake is on the Heartbeat, compare it to the factory LSA or LS9 superchargers, and you’ll see how much work we put into getting optimum flow in the front end.”

Front view of a Magnuson Heartbeat supercharger – note the dual intercooler core inlets and outlets on either side of the cover, and the bypass valve actuator on the left hand side of the case.

Another feature that may be seen as an advantage for some potential users is the fact that the Heartbeat design allowed an in-depth look at the noise, vibration, and harshness (NVH) characteristics of the supercharger, making for a quieter unit – great if you like flying below the radar, though some may miss the additional blower whine. In fact, Magnuson has gone to a good deal of trouble to keep the power civilized with the Heartbeat supercharger. An internal bypass valve opens during low-demand operation, reducing parasitic loss; Magnuson claims the blower consumes just 1/3 horsepower during 60 MPH cruise operation.

The Heartbeat system for the automatic transmission L99 5th gen Camaro retains the Displacement on Demand functionality, and both the Camaro systems and the 6th gen Corvette Heartbeat supercharger carry California Air Resources Board EO numbers for 50-state street legality.

Keeping Your Cool

With the Heartbeat, we spec’ed a pair of intercoolers that’s probably overkill for most people, but we wanted to try and eliminate the problem of heat-soak completely – Matt Hately

We asked Hately how the new Heartbeat intercooler compared to their previous “modular” system intercooler, and he answered, “While they perform the same function, they are a completely different design, so it’s hard to compare – it’s not exactly apples to apples. The older-style intercoolers work well enough, especially for someone that’s drag-racing or street driving. With the Heartbeat, we spec’ed a pair of intercoolers that’s probably overkill for most people, but we wanted to try and eliminate the problem of heat-soak completely.”

Heat soak can be a major engineering challenge when you’re trying to build an intercooler that can take extended periods of hard operation. In short-duration applications like drag racing, an icewater reservoir is often used as a heat sink instead of an external heat exchanger, but when you’re running wide open for more than a few brief seconds, the intercooler system has to be able to reject heat to the outside atmosphere as quickly as the engine produces it, or performance will suffer as the intercooler stops doing its job.

Per Hately, “We wanted to build a supercharger for that guy that takes his car to Willow Springs [a road course located in California’s high desert] on a July day when it’s 105 degrees and drives the crap out of it, then takes it to a flying mile event the weekend after. The recovery times and IATs [intake air temperatures] are pretty phenomenal. The new intercoolers even have dimpled passages, so that the water turbulates and cools more completely. They’re modeled after Formula 1 oil coolers, which obviously have to work under pretty extreme conditions. You can drive wide-open (under controlled conditions on a closed-course, of course) in 100 degree heat, and see IATs of just 25-30 degrees above ambient. That sort of intercooler performance is unheard of in a Roots-style supercharger.”

Of course, once removed from the intake air, that heat has to go somewhere, and Hately says they’ve improved that as well. “In the Heartbeat systems, we’ve upgraded the front-mount heat exchanger as well, which helps supplement what the internal intercoolers are doing.”

The Hard Work Done For You

Improved performance is obviously the ultimate goal for any supercharger installation, but nobody wants a system that takes days of labor to install, or that requires a bunch of custom fabrication. Many owners aren’t shy about modding their cars, even straight off the showroom floor, but might balk at the prospect of having to cut sheetmetal to facilitate an installation.

Rather than using inexpensive rubber hose and fittings, Magnuson actually tooled up for custom hard lines to go with their Heartbeat superchargers.

Magnuson’s supercharger systems have always had a reputation as being well-engineered and straightforward to install; per Hately, the new Heartbeat kits are no different in that respect. “It’s roughly the same,” he says, comparing the complexity of installation to the older systems. “Though we’ve made a lot of improvements in the chassis kit to make it both easier to install and to give it more of an OE-look, including better connectors and hoses that are cut to length. We get just as many compliments about the overall fit and finish as we do about the performance.”

Magnuson's advanced R&D and manufacturing capabilities have allowed them to produce an OEM-quality product consistently and at an affordable price.

Taken in total, the new Heartbeat superchargers represent a huge investment in R&D, and point the way forward to what you can expect to see from Magnuson in the future. Per Hately, “The Heartbeat was over 18 months in development. The only thing that carried over were the rotors – everything else was rethought from the ground-up, right down to the way the pulley is mounted (cantilevered to put the belt load over the bearings for longer bearing life). Probably the biggest challenge was making sure we could manufacture it. At the time, it was a big departure from how we machined and built superchargers. Now, many of our new systems, like the Audi systems or the new Corvette C7 Stingray kit, use the same overall principles.”

Magnuson manufactures supercharger kits for pretty much any LS configuration, from Corvettes to trucks to hot rods.

The Bottom Line

Of course, the whole point of a supercharger upgrade is to make horsepower, and that’s where the Heartbeat shines. “Almost everyone asks, ‘How much more power does it make over your old systems, and how much power is it capable of?’,” Hately admits. “The Heartbeat makes about 40 more rear-wheel horsepower than our traditional superchargers at the same level of boost. On a LS3 Corvette or LS3 Camaro it makes about 515-530 rear-wheel horsepower when the rest of the car is stock. As for how much power it will make? The Heartbeat definitely breaks the myth that you need a 2.9-liter or bigger screw-type blower to make big power. ADM Performance built a Texas-mile record-winning CTS-V with a 427 running the Heartbeat, and it made 900 wheel horsepower. Lingenfelter made over 900 crank horsepower on a 376, and said it was the most power they’d ever made from a 2.3-liter supercharger. Where else can you make that kind of power, and have it be daily driveable?”