Performance racing bearings are one of those vital parts of an engine build that are often misunderstood and paid little consideration due to a lack-luster level of excitement. Well before you can start salivating over a big shiny power adder, laying the foundation to support the power comes down to bearings.

The bearings that came in your car from the factory were optimized for longevity and reliability. Conservative engineering is the name of the game for the OEMs in most cases, so as we horsepower junkies start to add more and more, priorities change.

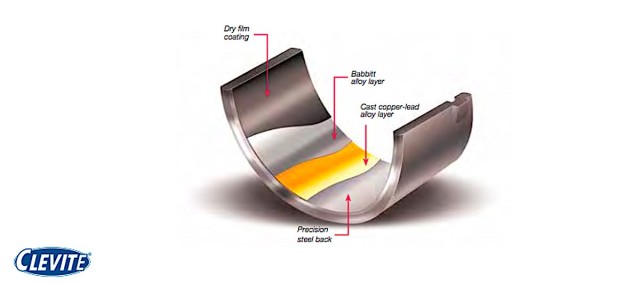

This cutaway of a Clevite bearing shows us the layers of material including the soft babbitt coating. Image source: Mahle Aftermarket

Mahle Aftermarket is a staple name in engine components and one of the authorities on Clevite race bearings. In this informative clip Bill McKnight of Mahle illuminates the reasoning behind softer bearings for race applications.

“Clevite bearings don’t come in engines in cars today, the factory bearings are made out of a material called bi-metal aluminum. The shiny metal surface is aluminum with a silicon alloy that’s extremely hard and wears like iron,” McKnight prefaced.

It may sound like a positive to have the hardest bearings in a high load scenario like a race engine but remember the bearing surface is made up of the oil film trapped between the rotating assembly and only supported by the bearings. When the power-stroke load exceeds the oils ability to stay in place metal-to-metal contact can occur, and that’s when catastrophic problems can happen.

Reduced oil film can cause wear patterns on a bearing like this. Image source: Mahle Aftermarket

“For race engines like yours you might think well why don’t I want those aluminum bearings? The problem is when you start making more than about 600 horsepower you start doing crazy things to the inside of the engine,” McKnight continued addressing “Alex the car girl.”

“The firing pressure pushing the connecting rod down on the crankshaft is really high, and the bearing is the only thing between that, other than the film of oil. As the power gets higher we start stressing that film of oil, and it gets thinner, and thinner — and it can get to the point where the bearing will actually touch the crankshaft,” he explained.With a very hard bearing there’s nothing to give and nothing to deform. If it touches the crankshaft we’re going to have aluminum bearing welded to the crankshaft.”

A seized bearing will quickly snowball into a spun bearing, deficient oiling and massive heat buildup, the impending engine failure is sure to be spectacular — definitely not something you want to deal with at the track. In order to make a high-horsepower racing engine survive a different approach is necessary.

“The H-Series Clevite race bearings have a surface material called babbitt that’s a soft material. Babbitt is actually made from a combination of tin and lead, and it actually melts at 450 degrees so if it starts to rub a little bit from the pressure of the crankshaft it will wear down or deform a little bit and the engine keeps on going,” McKnight illustrated.

The utility of this metallurgical design is made very tangible as McKnight relays an anecdote of Top Fuel teams experiencing up to .040-inch of flat spot squish on rod bearings after a flaming 10,000 horsepower, 4-second run.

So if you have a 600+ horsepower build in the works, make sure you are selecting the right bearing to keep that engine alive. Clevite can offer an insurance policy against some nasty bottom-end woes.