When Moser Engineering says its products are made in the USA, it means it. Moser has worked hard to create a logistical network that allows most of its products to be proudly made in the United States. That means, as turmoil in the world grows when it comes to products or materials, Moser will still be able to honor its quick turnaround promises.

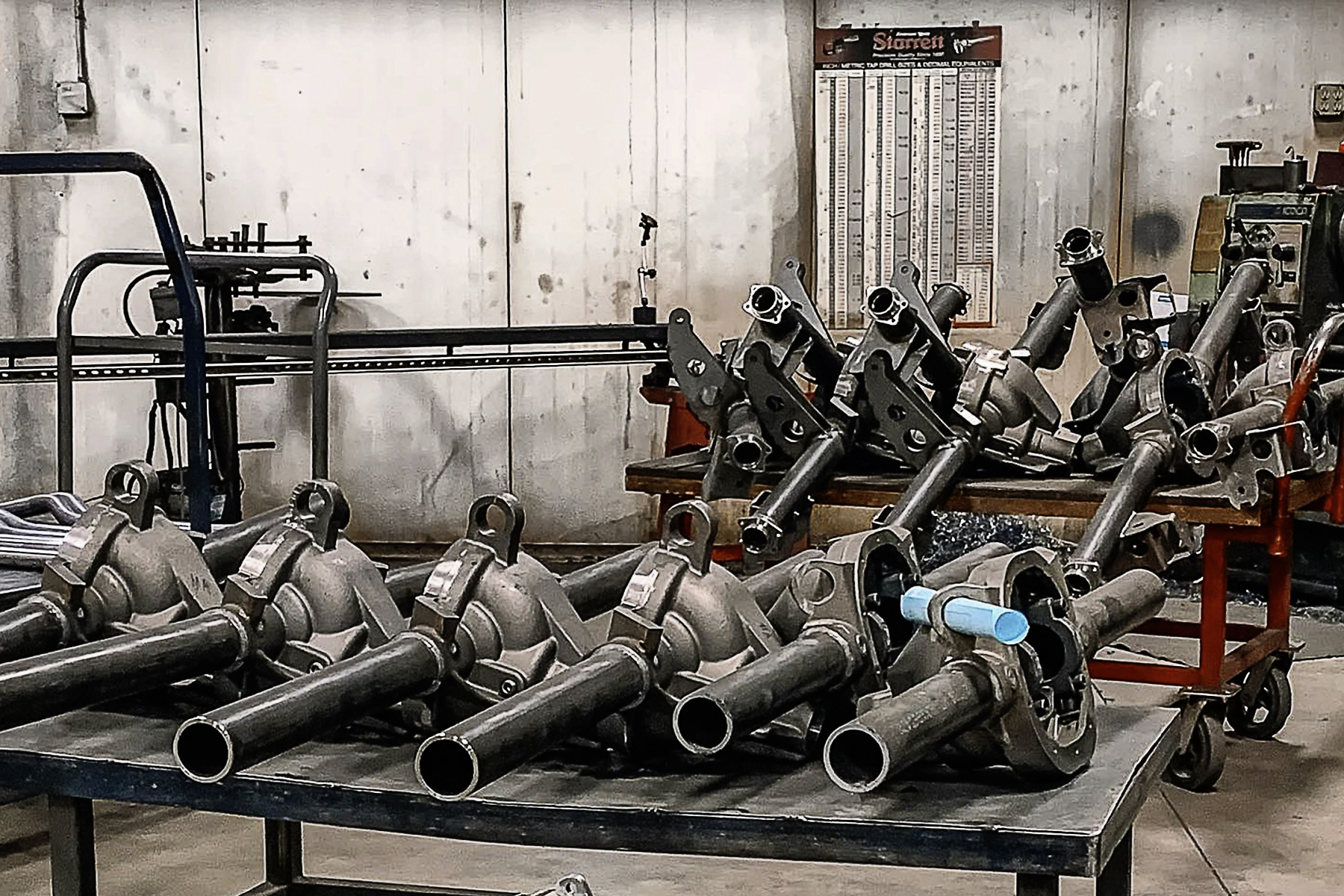

Moser has a massive facility in rural Indiana that ships out rearends, axles, and other suspension parts each day. Racers can even stop by the company’s headquarters and pick up parts they’ve ordered on the way to an event.

“All Moser Housings are made, stamped, or cast here in the USA by Moser Engineering. Our center section cases, rearend covers, eliminators, and housing ends are all made here. Our axles use only U.S.-made steel. They are forged, machined, and heat-treated here in Portland, Indiana. It is not uncommon to pull into our parking lot and hear the hammers forging our axles less than a mile from our Moser campus,” says Moser’s Jeff Anderson.

That level of investment in the local economy and workforce has aided Moser’s ability to avoid most outside pressures that tariffs can put on a manufacturing business. This is something the Moser family doesn’t plan on changing anytime soon.

Our two facilities are spread out here with well over 100,000 square feet of manufacturing space to help us meet our high standards since we started in the 1980s. What does all this mean? It shows our commitment to U.S. manufacturing and using U.S. labor at a time when some choose to take shortcuts and import. We will not feel the effects of tariffs directly, We will not have delays like so many did in the past and are experiencing now. We will still meet our standard two-day turnaround on the highest quality custom-made to order driveline components,” Anderson states.

In the video above, we take you on a behind-the-scenes tour of Moser’s facility. You get to see what goes into making the products and how hard the company works at providing top-tier service to its customers.