Updating your vintage Chevy to electronic fuel injection (EFI) is one of the best ways to infuse better drivability, reliability, and an increase in fuel mileage. Tanks Inc. has been supplying fuel storage solutions for over 30 years. They offer a variety of polyethylene, stainless steel, mild steel, and alloy-coated steel gas tanks for street rods, muscle cars, and classic trucks, designed to simplify EFI upgrades. Tanks has just made upgrading your 1967-1970 Chevy Impala’s fuel supply easier with its new stock-style Impala tanks for Chevy’s B-body platform.

Tanks Inc. introduces these new EFI-ready fuel tanks for 1967 and 1968 (left) or 1969 and 1970 (right) B-body Chevys, including the Impala, Bel Air, Biscayne, and Caprice.

These new offerings from Tanks Inc. are die-stamped for that factory-original appearance, but they are totally re-engineered to simplify the installation of fuel injection onto your vintage ride. Tanks Inc. now offers EFI-ready fuel tanks for 1967, 1968, and 1969-1970 Impalas. Based on Tanks Inc.’s 1965-1966 Impala fuel tank, each tank is designed to bolt in place of the original fuel tank and is 3/4-inch deeper, and 5 inches shorter than the factory tank.

No other manufacturer goes through the expense of making the tooling specifically for an EFI application that includes internal baffling – Justin Somerville, Tanks Inc.

The benefits of swapping your Chevy Impala, Bel Air, Biscayne, or Caprice fuel tank for these modern offerings from Tanks Inc. are quite numerous. To start, these new offerings are a complete EFI-ready fuel supply that includes the tank, fuel pump, and fuel level sending unit.

An EFI-Ready Tank

More than just a box to store your fuel, these new fuel tanks are designed to make the upgrade to EFI as simple as possible. Each 24-gallon tank is made from quality, die-stamped, galvanized steel for a factory appearance. Then, the exterior of each tank is powder-coated silver for long life, a clean appearance, and corrosion resistance. Internally, each tank features baffling necessary for late-model EFI engines.

Further evidence that this is an EFI-specific upgrade can be found inside the tank, where you’ll find an extra-large, 4.8-liter dual-tube baffled fuel tray for the fuel pump and sending unit to reside. This is necessary to prevent fuel pump starvation and prevent inaccurate fuel gauge readings. It also helps keep the fuel pump cooler.

With a carbureted vehicle, there is enough fuel stored in the carburetor’s fuel bowl to allow fueling during hard lateral acceleration. The precise nature of EFI’s ability to supply fuel is a benefit but can be greatly affected if the fuel pump cannot supply a constant volume and pressure of fuel to the injectors. The fuel pump losing its fuel supply, even for a short period of time, can result in the engine stumbling or possibly stalling at the most inopportune moment. The fuel tray in these tanks is designed to keep the pump and sending unit submerged to prevent this from occurring.

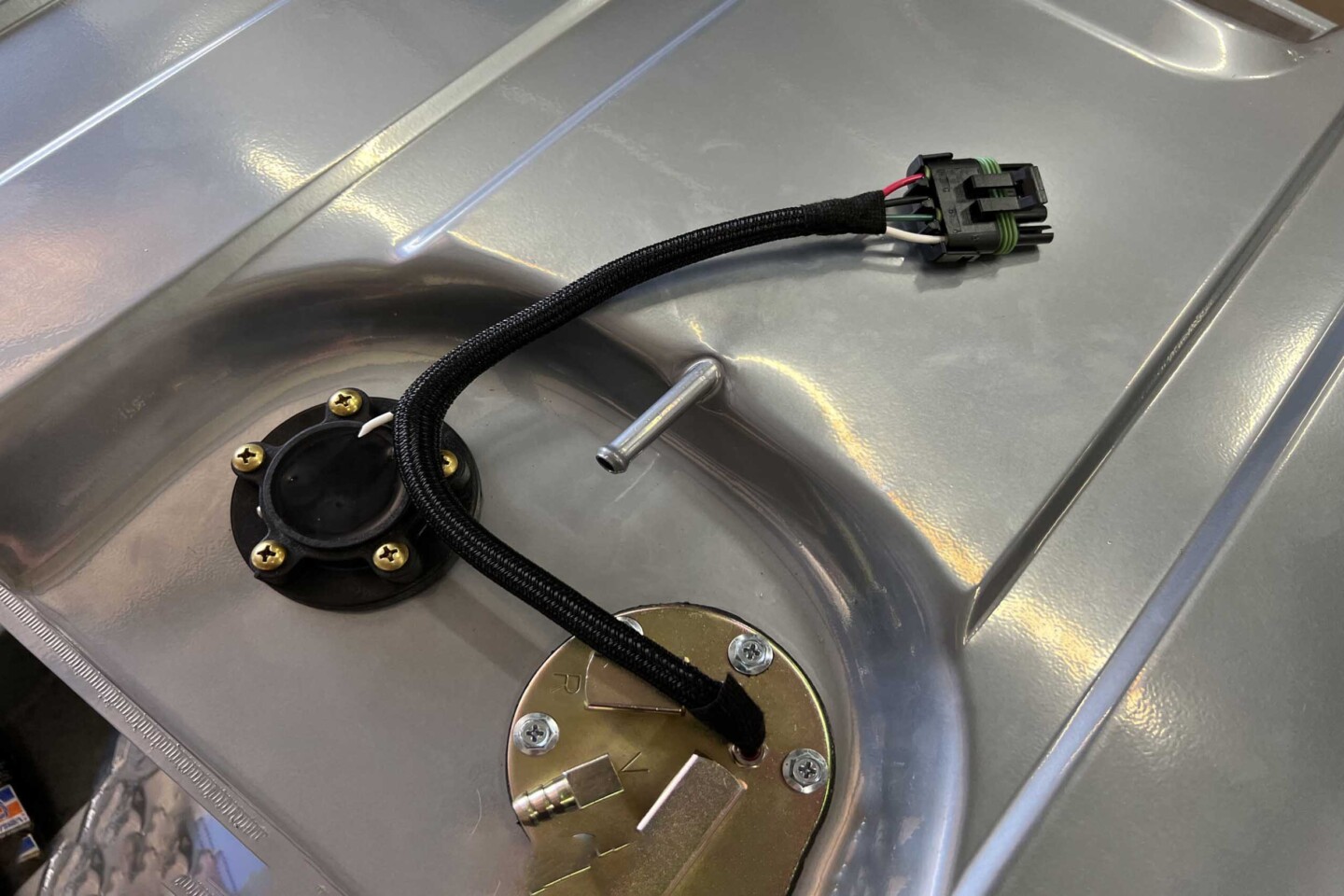

These Impala tanks are designed with a recessed area to allow for the fuel pump, lines, and sending unit.

These new tanks look factory when installed and work with the factory tank straps. They also allow easier installation because the fuel pump and sending unit are recessed into the tank body, allowing the necessary clearance so there are no modifications needed to your car.

Fuel Pump And Sending Unit Options For Every EFI

Every build is different, and these new Impala tanks allow for a broad range of horsepower and fuel gauge applications. To start, each tank utilizes a GPA Series fuel module. The heart of this module inside your Impala tank is the Walbro fuel pump, which can supply anywhere from 109 liters per hour — enough for GM’s factory Throttle Body Injection (TBI) systems — to 255 liters per hour, which is capable of sustaining up to 650 horsepower. The company also offers high-performance fuel pump module options to supply fuel for up to 1,000 horsepower. There is a handy guide to selecting the correct fuel supply for your application on the website. You can also speak with one of the company’s sales representatives to ensure you get the fuel supply necessary for your build.

When ordering your Impala tank, you can choose from a wide range of fuel pump capacities as well as the type of sending unit you need to match the gauges in your dash and your driving style.

Each drop-in pump module is made from heavy 10-gauge steel and features 1/4-inch NPT supply and return line fittings for easy routing of the fuel lines. There is also a barbed vent fitting so that your new Impala tank won’t build up pressure or vacuum during operation. The necessary internal wiring harness, supply line, return line, filter sock, and insulator sleeve are included with each fuel module.

These new Impala tanks are designed to use modern fuel-level sending units with the popular 5-bolt pattern that is so prevalent in the aftermarket. Fuel tank senders only read resistance to ground, so they work on all 6- through 24-volt systems, whether positive or negative ground.

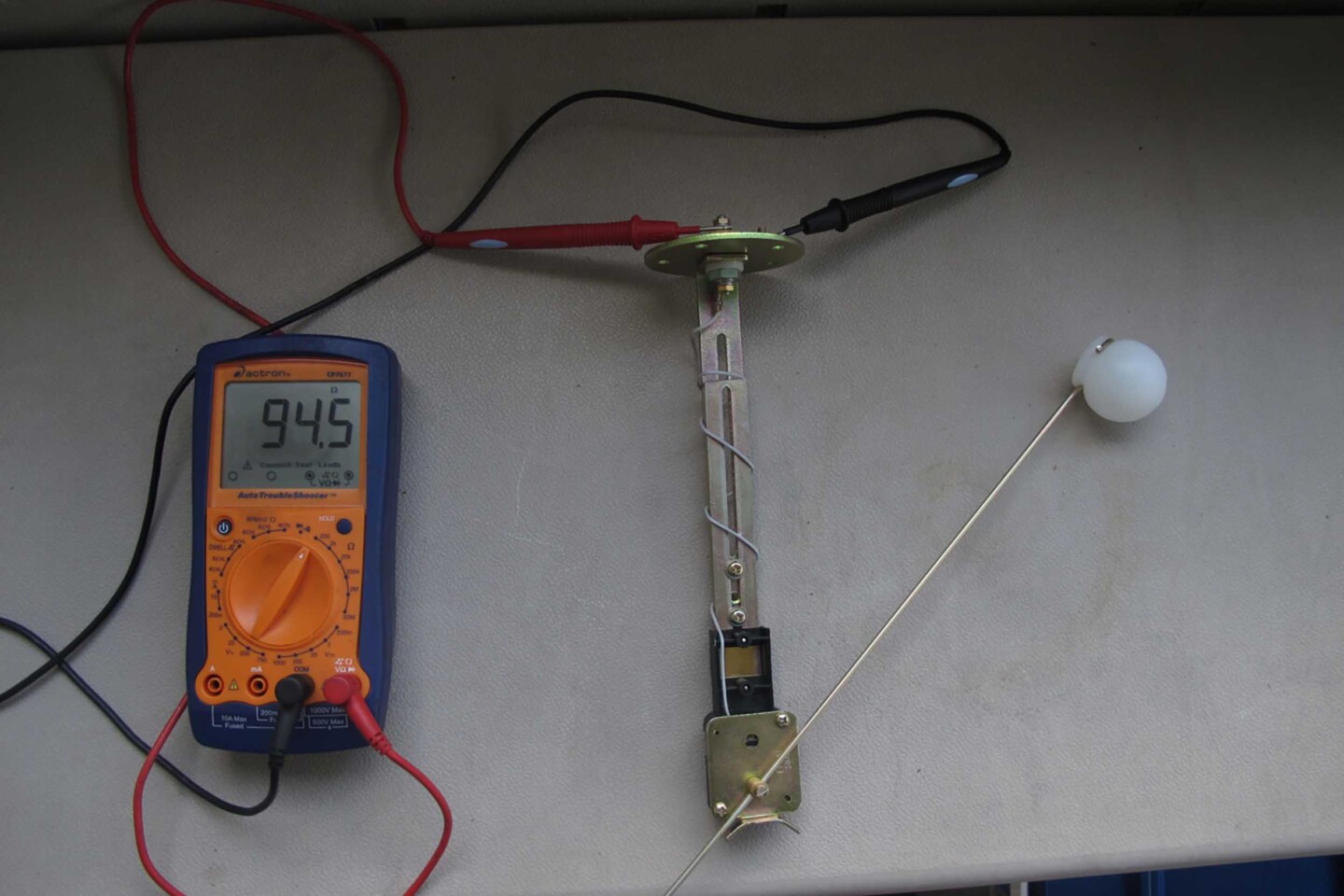

The fuel level sending unit changes the resistance to ground in accordance with the level of fuel in the tank. All gauges require a specific amount of resistance to register properly. Be sure to order the right sending unit resistance (listed in Ohms) for your gauges, through the drop-down menu on the Impala tank’s order page.

Beyond that, you can choose between a floatless type of sender or a float-arm, rheostat-style sending unit. A floatless sender has no moving parts to wear out and the tubular design acts as a damper, which prevents inaccurate readings due to fuel sloshing. A float-arm type of sender can be adjusted to work in a variety of tank depths ranging from 6 to 24 inches, whereas the floatless needs to be a specific length for the tank it is to be used in.

Fuel level-sending units are application-specific to the gauges they are designed to control. The resistance range of your fuel sender needs to match that of your gauge to get an accurate reading of how much fuel is in the tank. You will need to know what gauges you will be using to get the proper fuel level sending unit with your Impala tank. Here are many of the different gauge applications for the corresponding sending unit. The first number represents the empty Ohm reading, and the second number is the full reading.

Resistance Requirements Of Common Gauges

- Ford up to 1986 – 73-10 Ohms

- Ford 1987 & up – 16-158 Ohms

- GM up to 1964 – 0-30 Ohms

- GM 1965-1997 – 0-90 Ohms

- GM 1998 & up – 40-250 Ohms

- Mopar up to 1986 – 73-10 Ohms

- AMC 1950-1977 – 73-10 Ohms

- Autometer -240-33 Ohms is the most common however other ohm ranges are made

- Classic Instruments – 240-33 Ohms (excluding vehicle-specific gauge kits which use factory ohm range)

- Dolphin – 0-90 Ohms

- Dakota Digital – Programmable to work with most Ohm range senders

- VDO – 10-180 Ohms