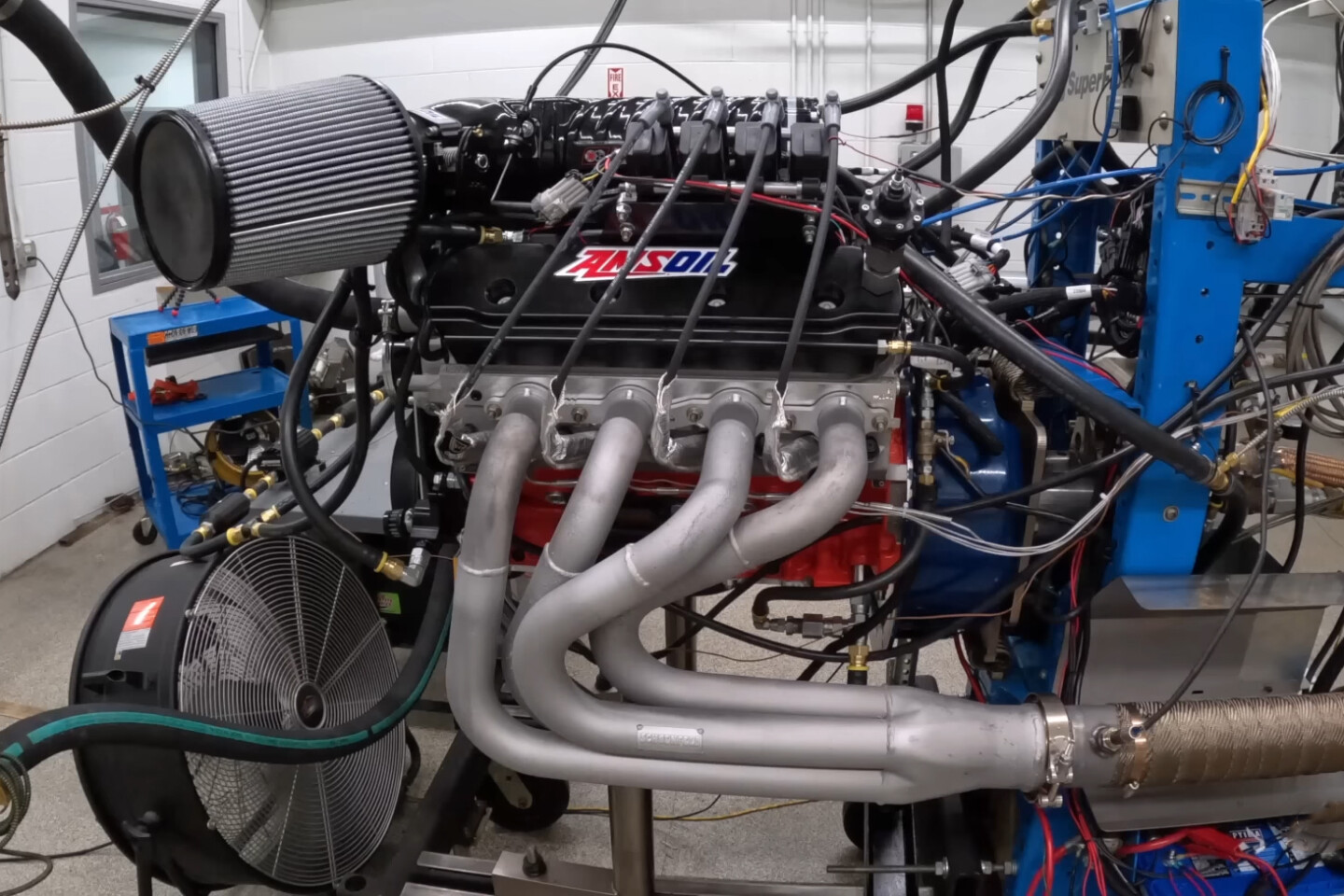

Back in the summer, we brought you this overview of AMSOIL’s 1,000-horsepower LS-based engine build designed to be a technology demonstrator for their line of lubricants. The results are in and not only did it make the 1,000-horsepower target, and easily live through all of the simulated cruising, drag racing passes, and autocross runs on the dyno without a hiccup, but now, AMSOIL is tearing the engine down to show the results of all that abuse on the internal components.

The Dyno Testing

Each test the engine was put through was individually designed to simulate a specific type of enthusiast use. The drag racing portion simulated a typical season of racing for the average enthusiast. Four weekends, with ten passes each weekend for 40 total simulated drag strip passes on the engine dyno. For the autocross simulation, the team based the acceleration and deceleration profile on Brainerd Raceway’s Donnybrook road course, with lap times ranging from 2:00 to 2:30, the test was three hot laps and a cooldown lap. That test totaled 8 hours of lap time once completed.

Chris Orr monitoring the engine during a dyno run. There were several carefully orchestrated simulation scenarios totaling up to 25 hours of run time on the engine.

For the daily driving testing, that was the tougher one to average. Combining acceleration profiles seen in street driving, highway driving, and some spirited freeway sprints (WOT, longer duration high-load pulls), that test was run for 15 cumulative test hours on the engine dyno. The total time spent on the dyno came in at 25 hours, and throughout the testing, the engine was lubricated by AMSOIL’s Dominator 15W-50 100-percent synthetic racing oil.

The Engine Results

As you might expect, once torn down the parts looked pristine. For a full breakdown of the parts used, you can refer back to the build article here, but the real keys to making the 1,000 horsepower reliably on pump gas were the Whipple 3.0-liter intercooled twin-screw supercharger and the Holley Dominator ECU. Managing intake air temps and being able to have fine control over all of the tuning parameters really takes a lot of the risk out of it.

Upon inspection of the main bearings, the only marks at all were a few small imperfections from some foreign matter contamination. “I don’t think you could get a much better result on the main bearings,” says Chris Orr, the engine’s builder and AMSOIL’s Mechanical Lab Manager. For reference, there was .0035-inch of main clearance, with a 50-weight oil.

The engine was built as a overly capable oil technology demonstrator, or, as Orr puts it, “to test oil, not parts.” The build concept worked, as the engine itself met all the design criteria while proving out the Dominator 15W-50’s mettle.

“At the end of the testing, we only have a light polishing [on the rod bearings],” says Orr. “There’s no overlay fatigue. There’s no significant wear to the upper bearing. There’s no indication that these bearings won’t live for a very long time in the engine.” Spoiler alert: that was the theme throughout the rest of the teardown. Orr stated several times, that they used good parts in the build, because they are testing oil, not parts. And, the Dominator oil kept everything in good enough condition to go right back into the engine when it’s reassembled.

So, as an engine project, the build is an unmitigated success, performing admirably in every challenge thrown at it and making 1,022 horsepower and 851 lb-ft of torque. The same can also be said as an oil technology demonstrator, as the condition of the parts shows that the Dominator oil is doing its job quite well.