Self-made, it’s the American dream for many. And for many, it will always be just a dream. Fortunately, that’s not the case for Brian Tooley. In a relatively short time, he has taken Brian Tooley Racing (BTR) from humble beginnings in his basement to its current 45,000-square-foot facility, which sits among the leaders in the automotive aftermarket industry. Following LS Fest East 2022, I had the opportunity to visit Brian at the newly expanded BTR headquarters and get a VIP tour from the man himself.

If you’re reading this article, you’ve likely heard of BTR. However, you may not know that Brian Tooley has over 17 years of experience in cylinder head design and development. So you could say maximizing cylinder head performance is where Brian’s heart is.

Walking in the front door at BTR, the only hints as to the magic that goes on out in the shop are the many plaques on the walls with but a few of the countless accomplishments that Brian and his team have achieved or been a part of.

Long before he created BTR, Brian started Total Engine Airflow in 1992. He had a brief stint at Holley from 1993 to 1995, where he helped develop the SysteMax cylinder head, intake, and camshaft packages. He sold his company to Summit Racing in 2004 and began helping Trick Flow Specialties develop CNC programs for existing heads as well as develop all-new cylinder heads. Brian stepped away from the automotive aftermarket in 2010, but luckily for us and the rest of the enthusiast industry, he returned after seeing a need for quality valve spring kits at an affordable price. And like that, Brian Tooley Racing was born.

Where There’s Opportunity

Initially, Brian was selling his Platinum LS valve spring kits out of his basement. He bought every bit of the spring manufacturer’s inventory and wore the phones out, calling shops to sell to. Of course, with his background, knowledge, and experience, it didn’t take long for people to ask if he would design a camshaft. The rest, as they say, is history.

In a very short time, the BTR facility has more than doubled in size. As you can see in the images, the newest additions to the building start where the new concrete exists. Of course, the BTR crew has already broken in the new space with a healthy burnout.

It was around 2016 that BTR moved into the original part of its current facility located in the bourbon capital of the world, Bardstown, Kentucky. At that time, the building was 15,000 square feet, and Brian made the somewhat bold prediction they would be out of room in five years. It only took four and half years for his prediction to come true. The reasons for BTR’s swift rise to the top are many. Two significant reasons are that Brian’s goal is to be the ultimate one-stop engine shop for customers, and he refuses to skimp on quality to make a dollar. For these reasons, BTR stocks more engine components at scale than almost any other shop in the industry.

You can’t sacrifice your reputation for money. You can always make more money, but you can’t make another reputation. –Brian Tooley, BTR

The sheer volume of inventory of BTR parts and other manufacturers’ supplied components is mind-blowing. As we casually walked through the facility, Brian pointed in one direction to six pallets of nothing but Magnuson superchargers, then pointed in the other direction at a wall stacked to the roof with Dart and GM blocks, as well as assembled short-blocks. Another aisle was lined with a year’s supply of lifters. Yes, you read that right. Upon seeing the parts shortages back in 2019-2021, rather than go with a different brand or a different supplier simply because he could get them, Brian chose to purchase a year’s supply of lifters to ensure BTR customers would continue to receive the same quality product they were accustomed to.

Remaining Loyal To The Vision

That dedication to quality is the reason for the latest expansion. Brian’s goal of BTR being a one-stop engine shop requires that much of the work for designing, developing, and manufacturing parts be performed in-house to ensure everything meets BTR’s level of quality and performance. And when Brian says he wants everything in-house, he goes above and beyond to do just that. For example, in 2018, he hired his longtime mentor and good friend, Rick Smith.

Rick Smith, center, and Brian Tooley, right, with Brian Wolfe during the 2022 PRI Show. The incredible wealth of knowledge and experience between them in air flow, cylinder head design, and making power is invaluable.

If you don’t know the name, you should. Rick Smith co-founded Trick Flow Specialties in the early 1980s and is one of the pioneers in high-performance cylinder head development. Since joining Brian Tooley Racing, Smith has been responsible for designing all of its cast-aluminum parts. Along with creating the components themselves, Smith also designs the patterns for the sand cores that a foundry can use to cast the parts. The patterns are cut on the shop’s Takumi VC1052 3-axis CNC. The only thing not under the Brian Tooley Racing umbrella is a casting foundry, but maybe one day.

The newly added machine shop space looked massive when we visited last September. Now, it's filled with equipment to build engines and manufacture parts from start to finish in-house.

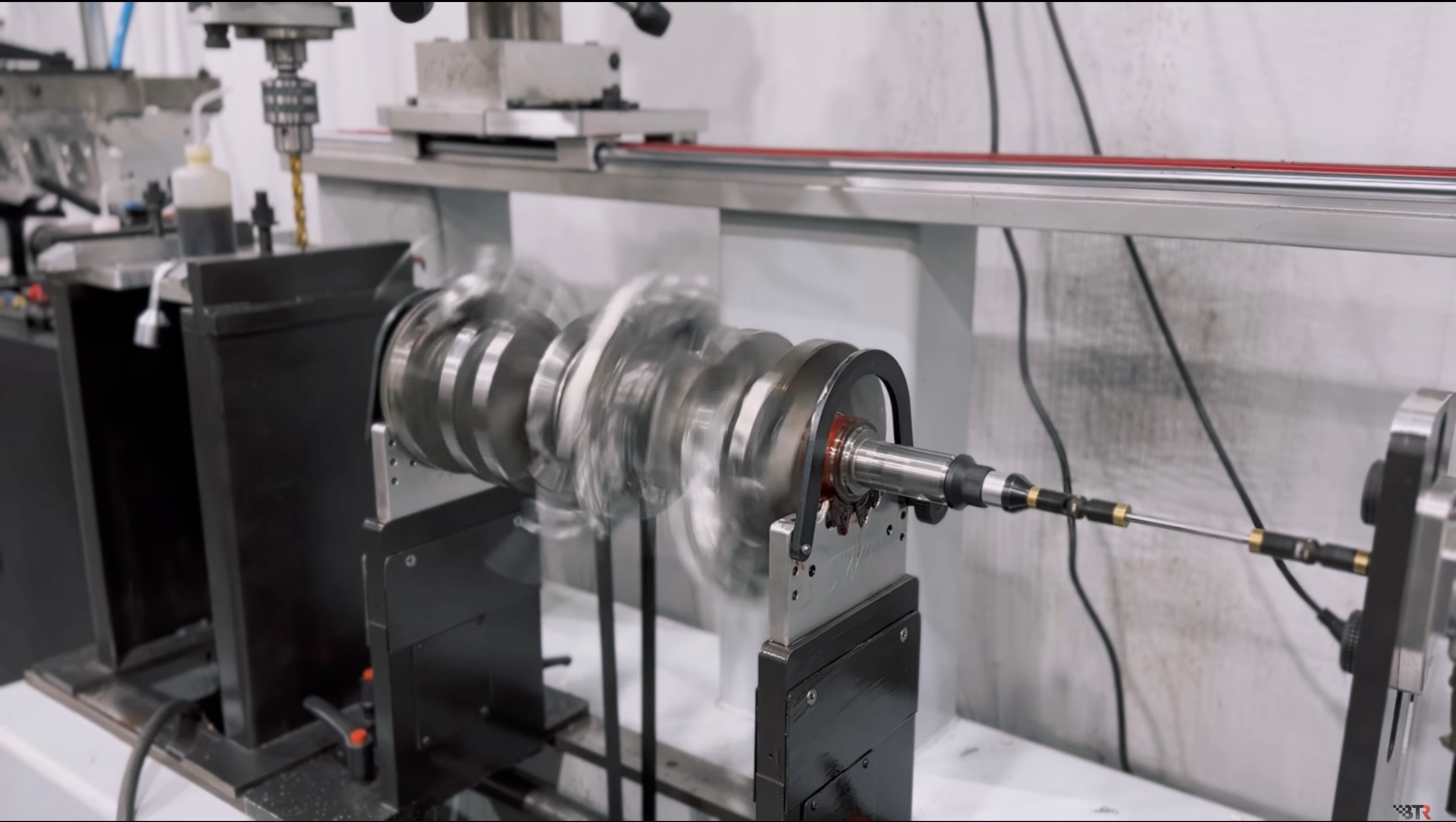

As Brian led us through the new 30,000-square-foot addition to the building, we were met with a complete machine shop scene in the making. A mix of equipment was being installed and set up while other equipment was already in use. He wasted no time diving right into explaining the operational machines on hand. The first machine we came to was an Adcole Model 911. This piece of equipment has been widely recognized as the “gauge of record,” or gold standard, for the past 40 years. It’s used to measure camshafts with exacting detail. With the ability to take 3,600 points of data per revolution, the Adcole 911 measures parameters like straightness, surface finish, roundness, runout, chatter, and cam lobe lift error. Although not entirely necessary, the machine is accurate to the hundred-thousandth of an inch (.00001 inch). As Brian put it, if you’re going to be in the camshaft business, you need this machine to test and measure your own cams and those of your competitors.

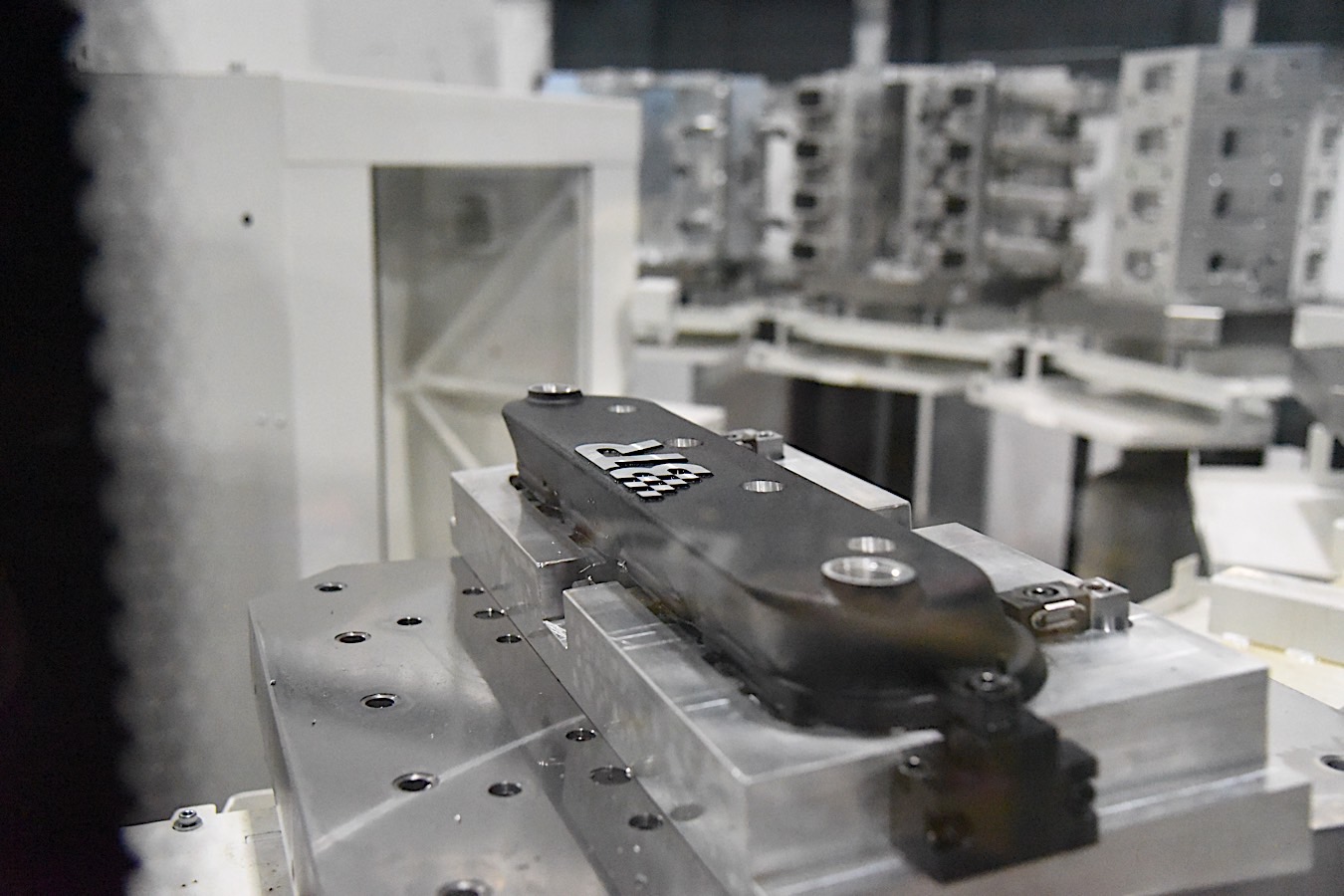

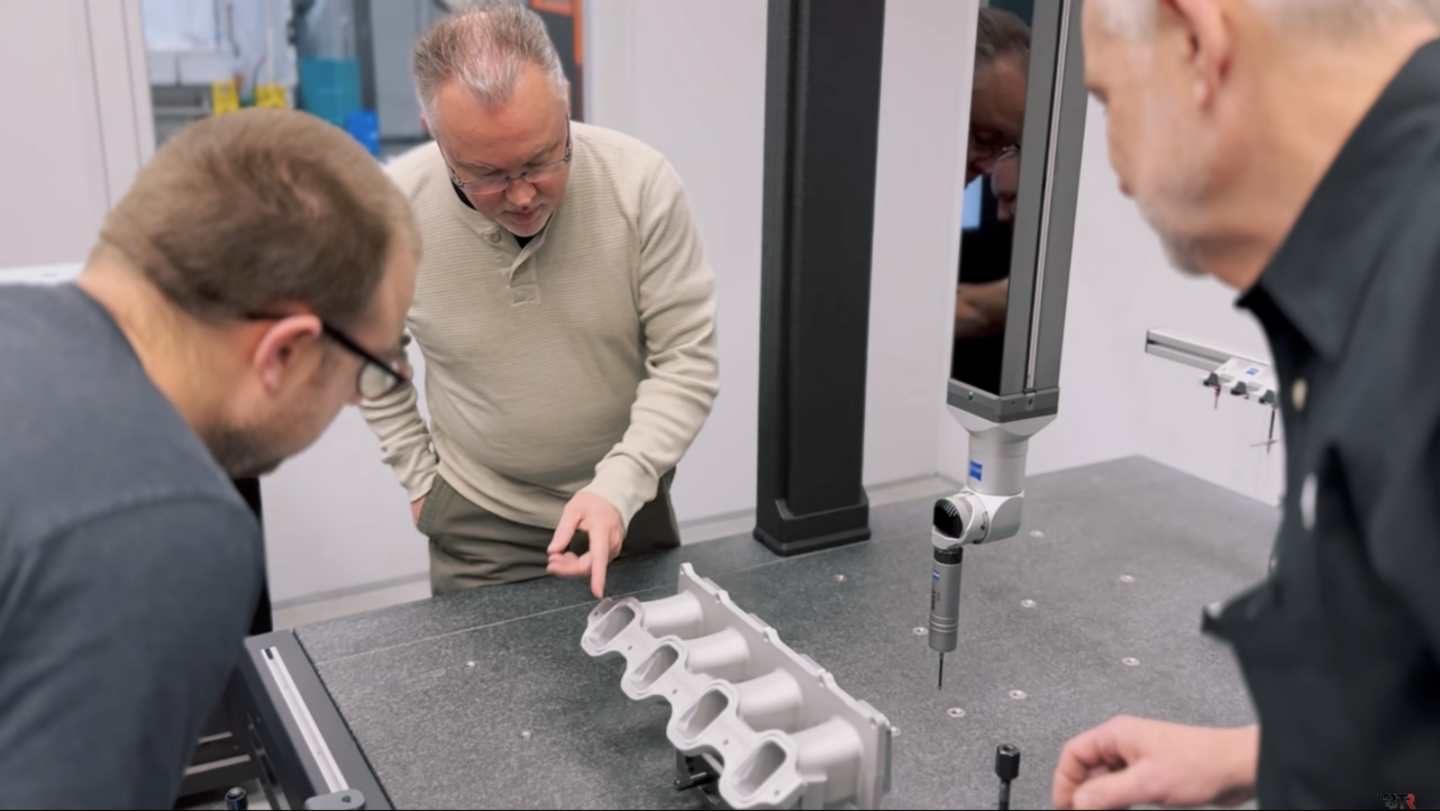

Next up on our high-tech tour was the Zeiss Contura CMM. This is another piece of equipment used for precisely measuring parts. This machine ensures castings and finished machined parts are all within spec. Unlike most manufacturers that only probe and test the initial setup part, BTR probes every component to ensure dimensional accuracy. This dedication to a higher standard has led to having the most accurate port alignment of any mass-produced cast intake on the market.

BTR goes to great lengths to ensure every part produced is the exact dimensions it’s supposed to be. This CMM machine probes each piece at many points to verify that it is dimensionally accurate.

Among the whirring of running CNC equipment were two machines in various stages of installation. To maximize efficiency while increasing production and maintaining the BTR level of exacting tolerances, Brian ordered a HURCO VMX series vertical machining center and a MAZAK Variaxis C-600 5-axis CNC. The HURCO machine is an all-in-one block machining center that can perform the processes that usually require multiple machines.

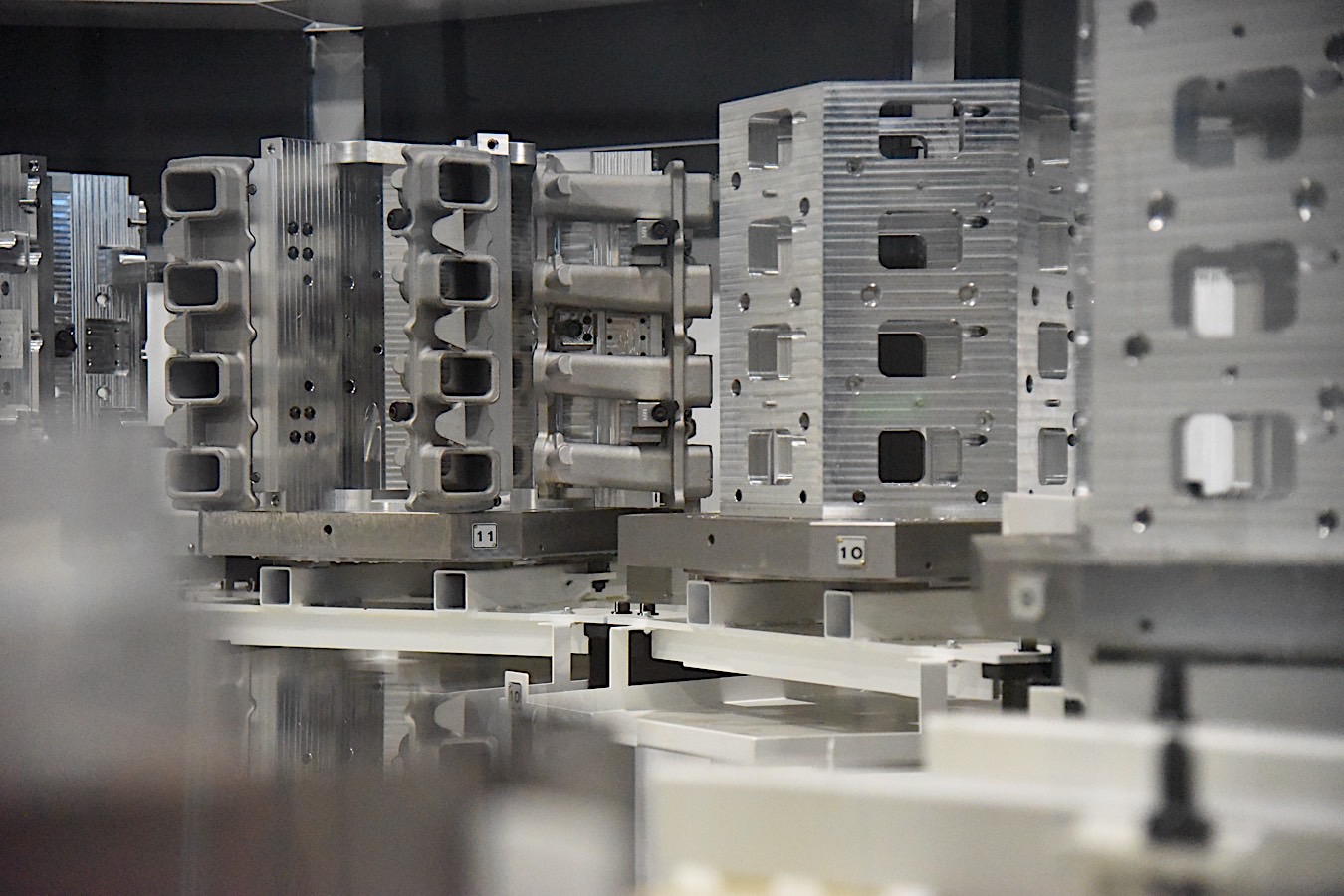

The MAZAK C-600 will allow BTR to drastically increase the production of machined parts like valve covers and intake manifolds, among other things. It can hold 90 different tools and up to 18 pallets. Each pallet can hold a number of cast parts ready for machining. Once completely loaded, it can run 24/7, only needing to stop to be unloaded and reloaded. The C-600 can also measure multiple points on a part to ensure castings are being machined to spec.

The Mazak is a large impressive piece of equipment capable of running for days once all 18 pallets are loaded with castings ready to be machined.

As you can see from the images of our tour and in the BTR shop video, all those machines and equipment that were either not yet delivered or still in crates are now unboxed, assembled, and running or on the verge of being operational. It’s been a short four and half months since we walked through what was then a primarily empty machine shop. Needless to say, things move quickly at Brian Tooley Racing.

In addition to the equipment we saw firsthand, the machine shop has since added what may be the crown jewel, at least to Brian. The Landis LT1e high-performance camshaft grinding machine is considered the best in the world for its ability to produce precision-ground high-quality camshafts repeatably. Since BTR designs all of its cam lobes in-house, it only makes sense to have the best cam grinding machine on the market in its shop.

This Landis camshaft grinder was not yet delivered when we visited, but it looks like the BTR guys are happy it’s in the shop now.

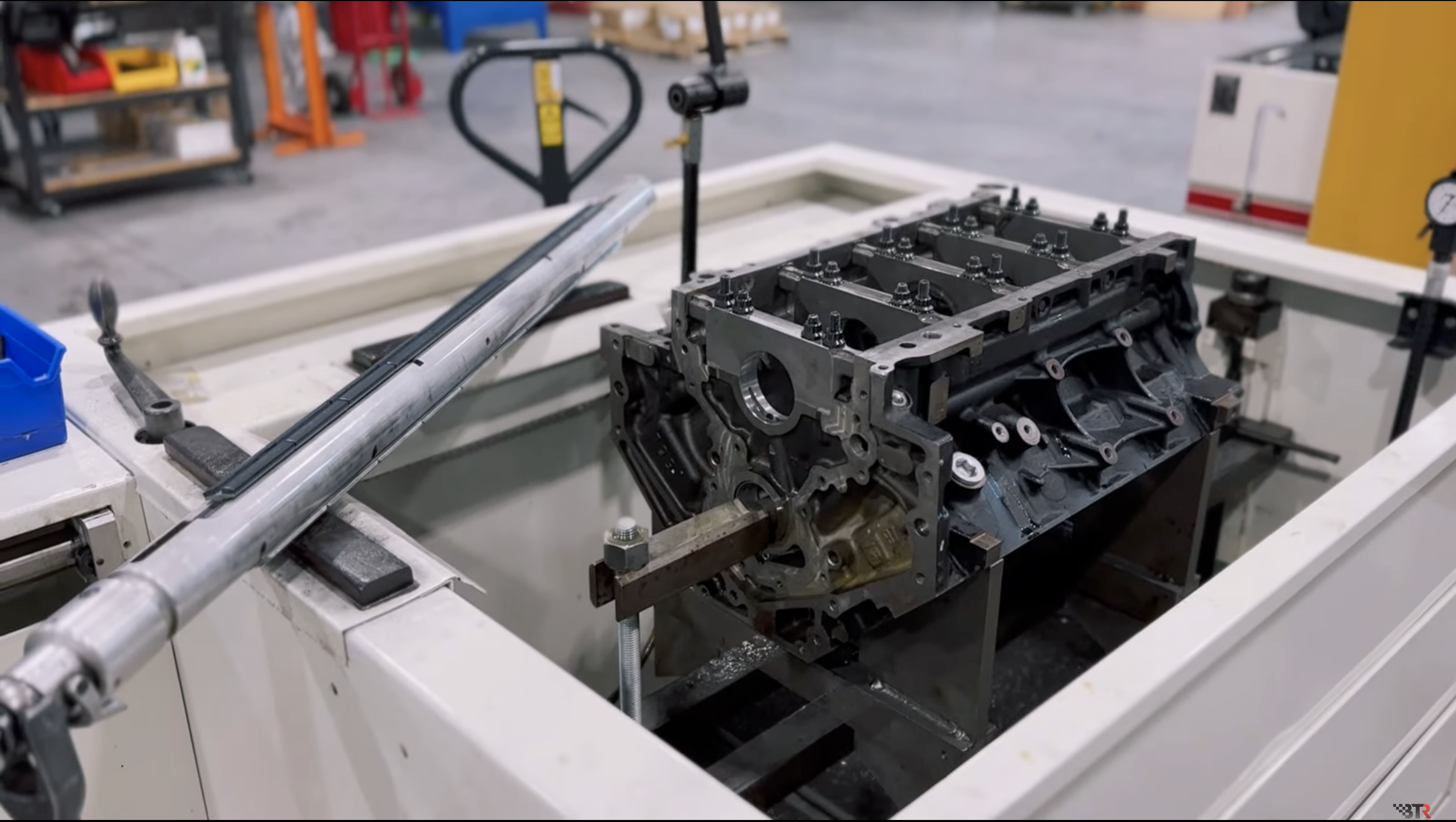

To complement the HURCO block machining center and add to the capabilities of BTR, a new Rottler H85A CNC block hone is handling any bore sizes other than the common 4.125-inch and 4.070-inch bores that the HURCO will take care of. To complete the package, there is a connecting rod hone, main cap grinder, line hone, and CWT crankshaft balancer. As a result, BTR can handle any aspect of preparing an engine block for a build.

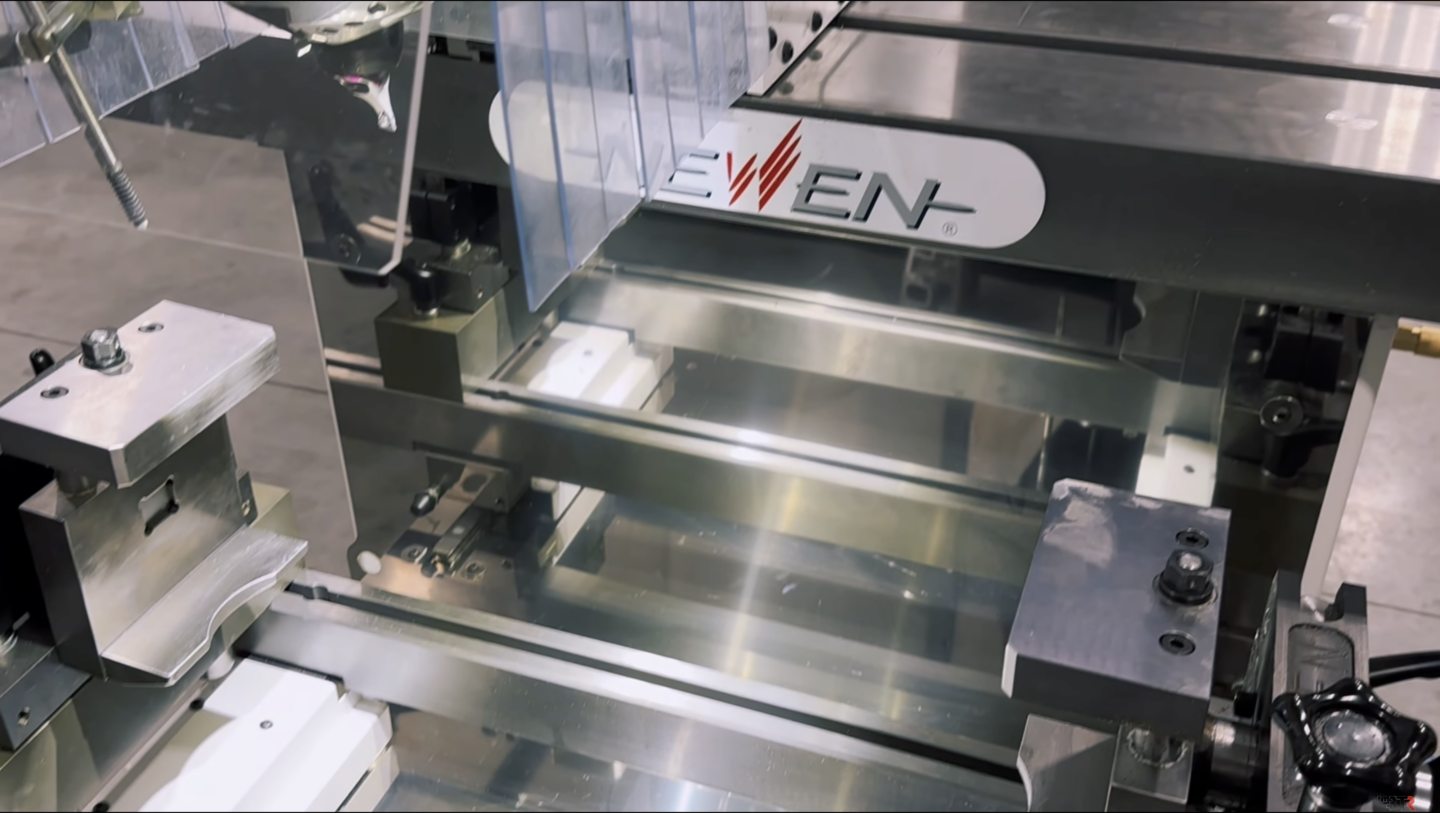

For those that watched the video and are paying attention to the one-stop-engine-shop theme here, you probably caught the part where Brian mentioned BTR now has a Newen CNC seat and guide machine. This machine can make quick changes to valve angles, widths, and radii on a cylinder head. That drastically speeds up the development stage in designing and producing cylinder heads. This means that Brian Tooley Racing will have cylinder heads coming.

The Newen CNC seat and guide cutting machine makes quick work of cutting valve jobs. This allows BTR to test various valve angles, widths, and other valve job specs on cylinder heads.

The Original Brian Tooley Racing Science Lab

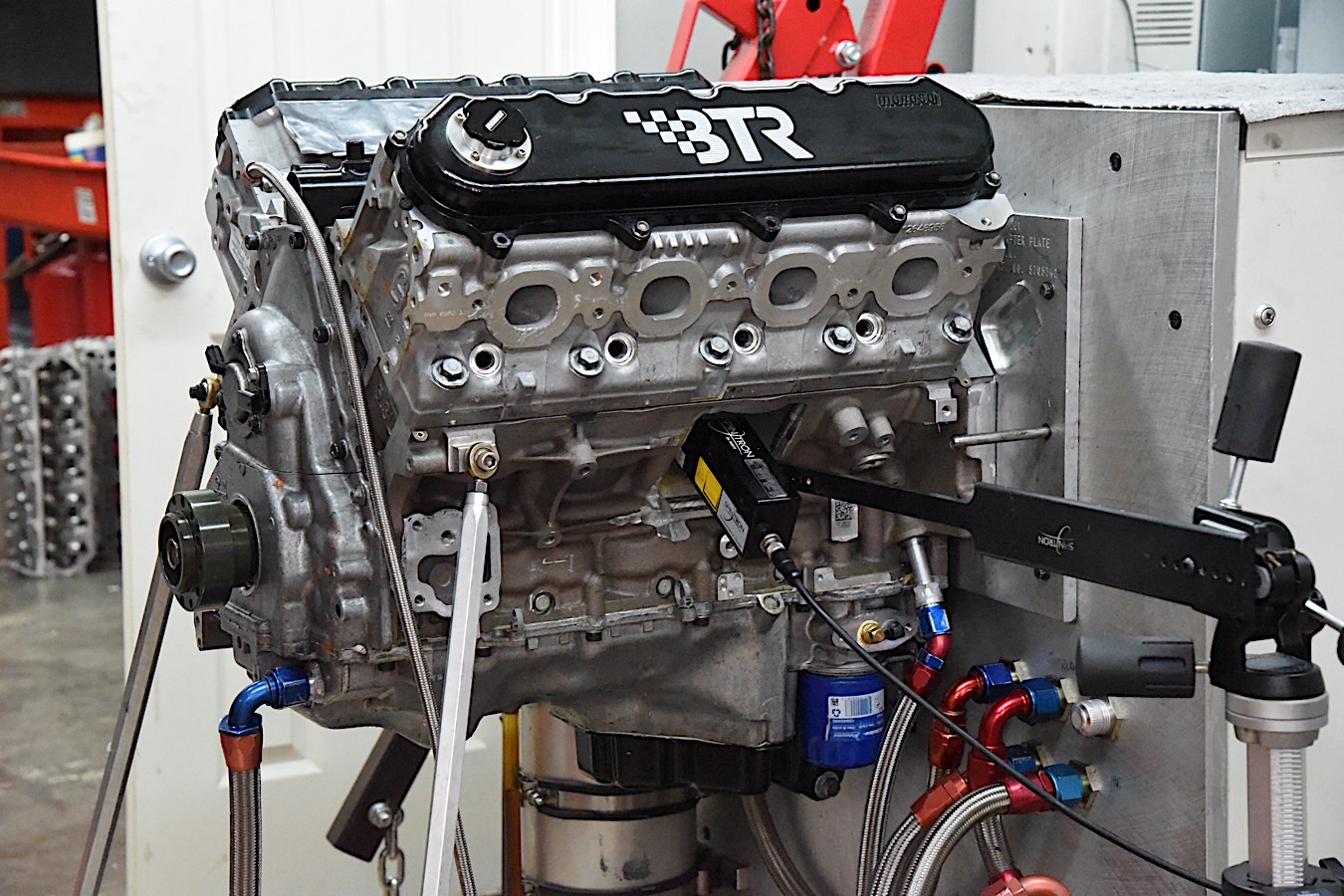

As we walked out of the machine shop in amazement, the tour wasn’t over just yet. Brian led us across the street and through rows of storage units to a much smaller building. While the current facility is more than impressive, you could say that this building tucked away behind a bunch of storage units is the science lab where Brian can put all of the ideas he and his team come up with to the test. This building houses the BTR Spintron machine as well as an engine dyno.

The Spintron tests camshaft lobe design by using an electric motor to spin an engine attached to the machine. Using a laser inside the modified block, the movement of the valvetrain components is precisely measured at various engine RPM. According to Brian, the Spintron is essential to designing camshafts. For a more in-depth look at the Spintron and an explanation of its capabilities straight from Brian, check out his video below.

As the tour ended, I wasn’t quite ready to stop listening to all the ideas pouring out of Brian’s mind. His passion for developing high-performance parts that efficiently produce lots of power is evident in the path he has led BTR along to this point. Brian and his team are making all the right moves to reach its goal of being a one-stop-engine shop and remain at the front of the industry. In addition, being able to design, manufacture, and machine everything in-house gives BTR a level of quality control that is hard to beat.

I can’t wait for the next opportunity to visit Brian and his team and see what they are coming up with now that all the pieces are in place to take Brian Tooley Racing to the next level.