Image Source: Stuart Lieby for Revvolution.com

It’s no question that Lexus’s IS300 is an awesome platform to build on, especially with the factory 2JZ-GE engine already capable of 600+ horsepower with supporting mods, but this IS300 is different, and in the best way possible.

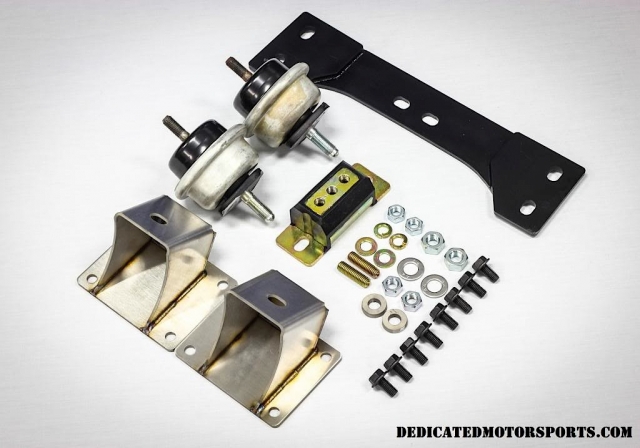

In 2010, Matt Owen was the first to complete an LS1 swap into his Lexus IS300, and it didn’t stop there. He had a deep passion for the build that he wanted to share with other IS300 owners who took an interest in his swap, so he started producing parts that would make it a lot easier for others to complete the engine transplant on their own. For about four years now, Owen has been selling the parts through his company, Dedicated Motorsports. His components have contributed to somewhere in the ballpark of 50 IS300 LS engine swaps worldwide – now, that’s impressive!

In 2010, Matt Owen was the first to complete an LS1 swap into his Lexus IS300, and it didn’t stop there. He had a deep passion for the build that he wanted to share with other IS300 owners who took an interest in his swap, so he started producing parts that would make it a lot easier for others to complete the engine transplant on their own. For about four years now, Owen has been selling the parts through his company, Dedicated Motorsports. His components have contributed to somewhere in the ballpark of 50 IS300 LS engine swaps worldwide – now, that’s impressive!

In conjunction with Dedicated Motorsports, Matt is the shop foreman, engine builder and fabricator for T1 Race Development which is where he developed and built his latest creation – a 2002 Graphite Grey IS300 powered by a twin-turbo 5.3L LC9 short block. With this build not being Owen’s first LS-swapped IS300, he knew what parts of the chassis he would need to modify to get the LC9 nestled right in there, but this time he had to account for two Precision 6266 turbos and manifolds.

Image Source: LS1Tech Forums

While Owen was waiting on more parts to arrive, he removed the ABS pump completely and got to work on tucking the chassis harness while eliminating any circuits that wouldn’t be used in the build. As you can see, tucking the harness looks like a massive headache, but Owen has done tucks on this chassis prior to this build and has most of the circuits and associated wire colors by heart – you could say that he knows what he’s doing.

Once Owen’s suspension parts started to arrive, he further continued his journey to get the proper clearance he needed for the radials. Aware of the fact that there was an aggressive amount of camber/toe sweep on the IS300s, Owen decided to fabricate his own control arms and modify the top hats to minimize the sweep as much as possible. The control arms and top hats came out great and work perfectly, keeping the tire as neutral as possible during launches and hard acceleration for ultimate traction.

Once Owen’s suspension parts started to arrive, he further continued his journey to get the proper clearance he needed for the radials. Aware of the fact that there was an aggressive amount of camber/toe sweep on the IS300s, Owen decided to fabricate his own control arms and modify the top hats to minimize the sweep as much as possible. The control arms and top hats came out great and work perfectly, keeping the tire as neutral as possible during launches and hard acceleration for ultimate traction.

As you can see, this picture was taken when Owen was testing out a tubular control arm. He scrapped this idea because of complications and fabricated some boxed control arms for ultimate durability.

The suspension Owen ended up going with in the rear was a pair of AFCO coilovers, which he inverted for a little less unsprung weight, and a pair of JIC Magic coilovers up front for the ride he desired. With intentions of putting down close to 1,000 horsepower, Owen needed to upgrade the factory rear end to handle all of the power, even though the stock differential can can handle up to 800 horsepower. He ended up going with The Driveshaft Shop‘s custom 9-inch rear end and a beefy carbon fiber driveshaft, also from Driveshaft shop.

With Trick Flow heads, an ATI Racing damper, Wiseco Pistons, Scat rods, and his own oil pan, turbo manifolds and engine/tranny mounts, Owen’s sleeved 5.3L LC9 and Tremec TR6060 transmission were ready to be nestled into its new place of comfort and coupled to a new MoTeC M1 ECU.

With Trick Flow heads, an ATI Racing damper, Wiseco Pistons, Scat rods, and his own oil pan, turbo manifolds and engine/tranny mounts, Owen’s sleeved 5.3L LC9 and Tremec TR6060 transmission were ready to be nestled into its new place of comfort and coupled to a new MoTeC M1 ECU.

The M1 ECU is paired in conjunction with MoTeC’s new C125 display LCD display, which can be used to monitor a plethora of data channels and is really easy to read – it also looks great and adds great racecar flare to the lightweight, basic interior of Owen’s IS300. Once the engine was in and connected to the MoTeC M1 via custom mil-spec harness by Race Spec, it was time for some tedious but necessary tuning by T1’s Tony Palo on their in-house dyno, and then it was off to Houston for TX2k14 – where all the fun happens!

Owen’s build is definitely an achievement – he performed all of the work necessary to make this car what he envisioned in his mind, maybe even better, and gets to showcase all of his own parts so that enthusiasts and consumers alike can see that a build like this is really possible. Not everyone has the tools to accomplish the same goals as Owen, but with his components available for purchase, an LS-powered IS300 is that much more tangible to the average do-it-yourselfer. Props to Matt Owen on the awesome build and for providing us with one of the nicest IS300’s around to lay our eyes on.

Owen’s build is definitely an achievement – he performed all of the work necessary to make this car what he envisioned in his mind, maybe even better, and gets to showcase all of his own parts so that enthusiasts and consumers alike can see that a build like this is really possible. Not everyone has the tools to accomplish the same goals as Owen, but with his components available for purchase, an LS-powered IS300 is that much more tangible to the average do-it-yourselfer. Props to Matt Owen on the awesome build and for providing us with one of the nicest IS300’s around to lay our eyes on.

Below is a video from TX2k14 where Owen’s IS300 puts down 861 horsepower on the dyno – enjoy!

Also, here is a link to the beautiful full feature of Matt Owen’s car by Stuart Leiby for Revvolution.com