Hydraulic roller lifters have been a popular choice for engine manufacturers since the 1950s and are still commonly found today. Upgrading your hydraulic roller lifters is a great way to squeeze more power out of your  motor in combination with a more aggressive cam and raising the rev limit safely.

motor in combination with a more aggressive cam and raising the rev limit safely.

One of the downsides to hydraulic style lifters is that they have very small oil passages and internals. These internals are extremely sensitive to foreign material blocking oil passages and possibly causing damage to the lifters and other engine internals.

Comp Cams‘ Billy Godbold has posted a video to their YouTube channel going over the basics of handling and caring for your hydraulic roller lifters before and during the install process.

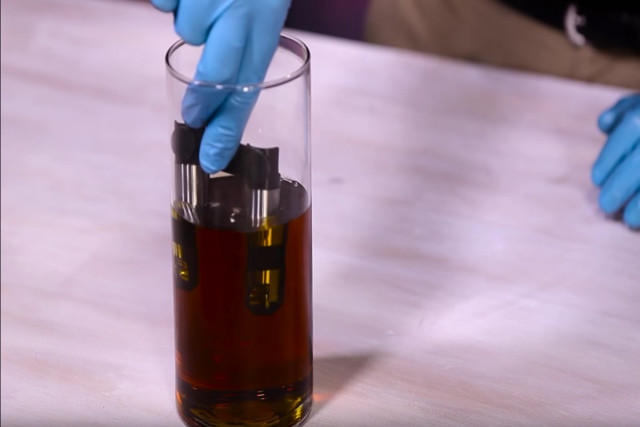

Before you begin the install, it is important visually inspect your lifters for any damage that may have occurred during shipping. Once you have verified that the lifters are not damaged, it is recommended that you dip your lifters in mineral spirits or a similar solvent to remove any contaminants and the rust inhibitor the lifters are coated in.

After they have been washed in the mineral spirits, soak the lifters overnight in a high quality break in oil. This will allow the oil to thoroughly lubricate the lifters and penetrate the needle bearings, then you will be ready to install them.

After they have been washed in the mineral spirits, soak the lifters overnight in a high quality break in oil. This will allow the oil to thoroughly lubricate the lifters and penetrate the needle bearings, then you will be ready to install them.

Once the lifters are installed, it is important to check for proper clearances and resolve any binding, locking or added resistance in the valvetrain assembly. Any problems left unnoticed will put extra strain on the lifters and will cause premature failure.

Once the lifters are installed and you are ready to button everything back up, it is important to clean the engine of any metal shavings, loose silicone or rag fibers. These foreign objects might block oil passages in your lifters before it ever sees the oil filter.