When it comes to home repairs, not all of us are aficionados of the MIG welder or masters of masking tape. In front of friends and family, we’ll posture and play along to demonstrate our mechanical prowess, but there are times when videos like these serve to help us further our knowledge base.

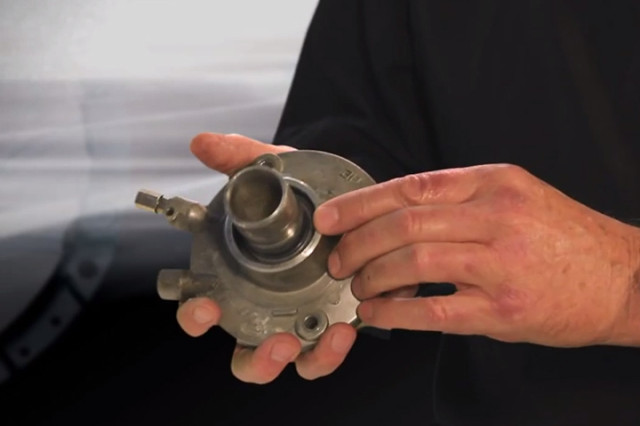

Here, we have Chris Astbury, sales manager at Mantic Clutch, giving us a quick lesson in the finer things concerning the LS line of slave cylinders as found in manual transmission applications. The scenario, such as it is, finds the slave cylinder’s thrust bearing to be worn out and causing shifting problems in the vehicle in question.

Our inner mechanic has us prop up the car on jack stands, whip out the socket wrench, and get to work popping out the slave cylinder. Hours later, the part is in hand, but this is where we might make a critical mistake that could add hours to time spent fixing the car.

Astbury explains that the new o-ring on the replacement bearing will conflict with the one already inside the slave cylinder. He removes the former and shows it clearly.

As Astbury points out, it’s possible to overlook the stock o-ring seal that lies inside the throwout bearing cylinder. When this happens and someone swaps in a new Mantic Clutch thrust bearing, the o-rings found in both old and new parts collide and perpetuate the slippery clutch problem. The simple solution is to remove the stock o-ring and slip on the new bearing, and the issue has been resolved.

It might seem like a simple piece of advice, but reassembling the clutch and transmission with both old and new o-rings in place will inevitably lead to having to do the job all over again, and nobody wants to R&R a transmission twice. Find more helpful advice and expert knowledge from Mantic Clutch on its YouTube page, and be sure to visit the company’s website for more announcements, pictures, promotions, and more.