There are a hundred things to remember to do correctly when you are building or re-building an engine for your ride. Of all those things, the correct valvetrain setup is important, and part of that is proper valve spring set up. In the video above, COMP Cams Valve Spring Engineer, Bradley Brown, takes us through the basic, yet critical steps to making sure you have your valve springs set up properly. Some of the key operations discussed and explained are install heights, clearances, spring loads, and break-in. Ignoring these vital aspects of valve spring installation is a common cause of engine failure.

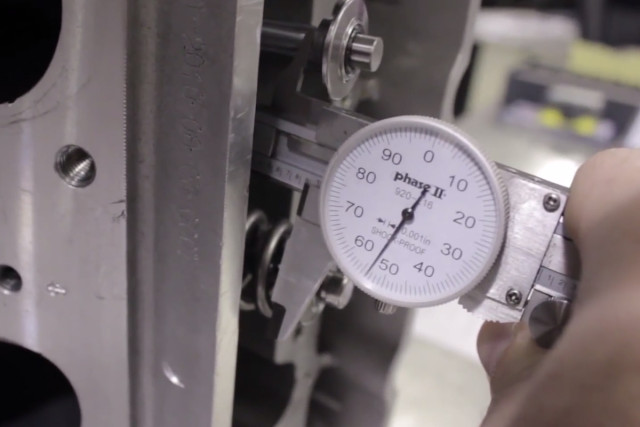

First, the springs must be completely cleaned and free of any debris. Then installation can begin with checking the install height. Bradley shows you exactly how to do this. Valve seat clearances are next. This is also a very important item on your valve spring install check list that if not done correctly can create huge problems.

First, the springs must be completely cleaned and free of any debris. Then installation can begin with checking the install height. Bradley shows you exactly how to do this. Valve seat clearances are next. This is also a very important item on your valve spring install check list that if not done correctly can create huge problems.

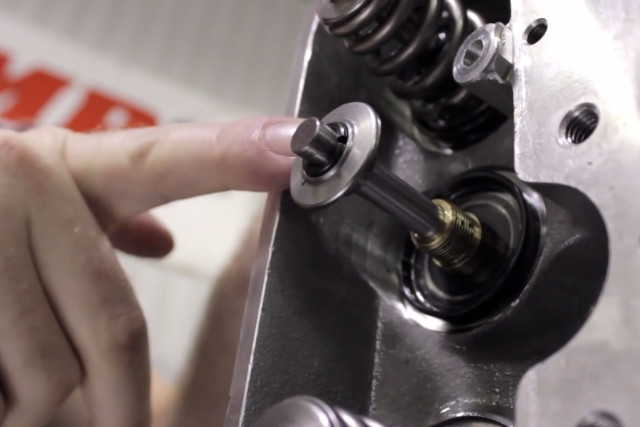

The next thing to assess is coil bind. If there is not enough room between the coils of the spring, the springs can bind and that can lead to damage and catastrophic engine failure. If the spring is binding and does not have enough space between the coils then you can do things such as change the shims, the locks, the spring, the valve, or you can go to the extent of machining the pocket to create the needed space between coils.

You should also always check the clearance between the retainers and the inside of the rocker arms once the springs have been assembled and installed. It’s important to make sure you have the correct rocker arm and retainer combination so that you have the correct rocker arm geometry.

Next is spring load. A new set of valve springs from Comp Cams will be matched for load consistencies, meaning that they have all be matched to within certain tolerances. But if you want to check the load, you can use a spring checker to be sure. This process is detailed by Bradley so you’ll know exactly how to check the spring loads.

Last is spring break-in, and this is a very important process. Once the springs have been installed they must go through a heat-set. Again, Bradley shows how to perform this simple, but critical operation in the video.