If you search the web, there seems to be some confusion about LS swaps and the wiring in of a torque converter clutch (TCC) switch. Some people are doing it, while others or not, and there is a right and wrong way. If you’re running an early non-electric transmission like a Powerglide, TH350, or TH400, you don’t need to worry about the TCC switch. Usually, these transmissions don’t offer a torque convertor lock-up feature. However, the TCC switch is a must if you utilize a more modern electronic transmission like a 4L60-E or a 4L80-E on a Gen III engine swap. Failure to connect the switch could result in transmission failure in the long run.

If you need a torque convertor switch wired in for your LS-swap project, BP Automotive makes the process very simple with its TCC switch (PN TCC-001). It will eliminate any wiring headaches associated with making the torque converter clutch function properly.

Installation

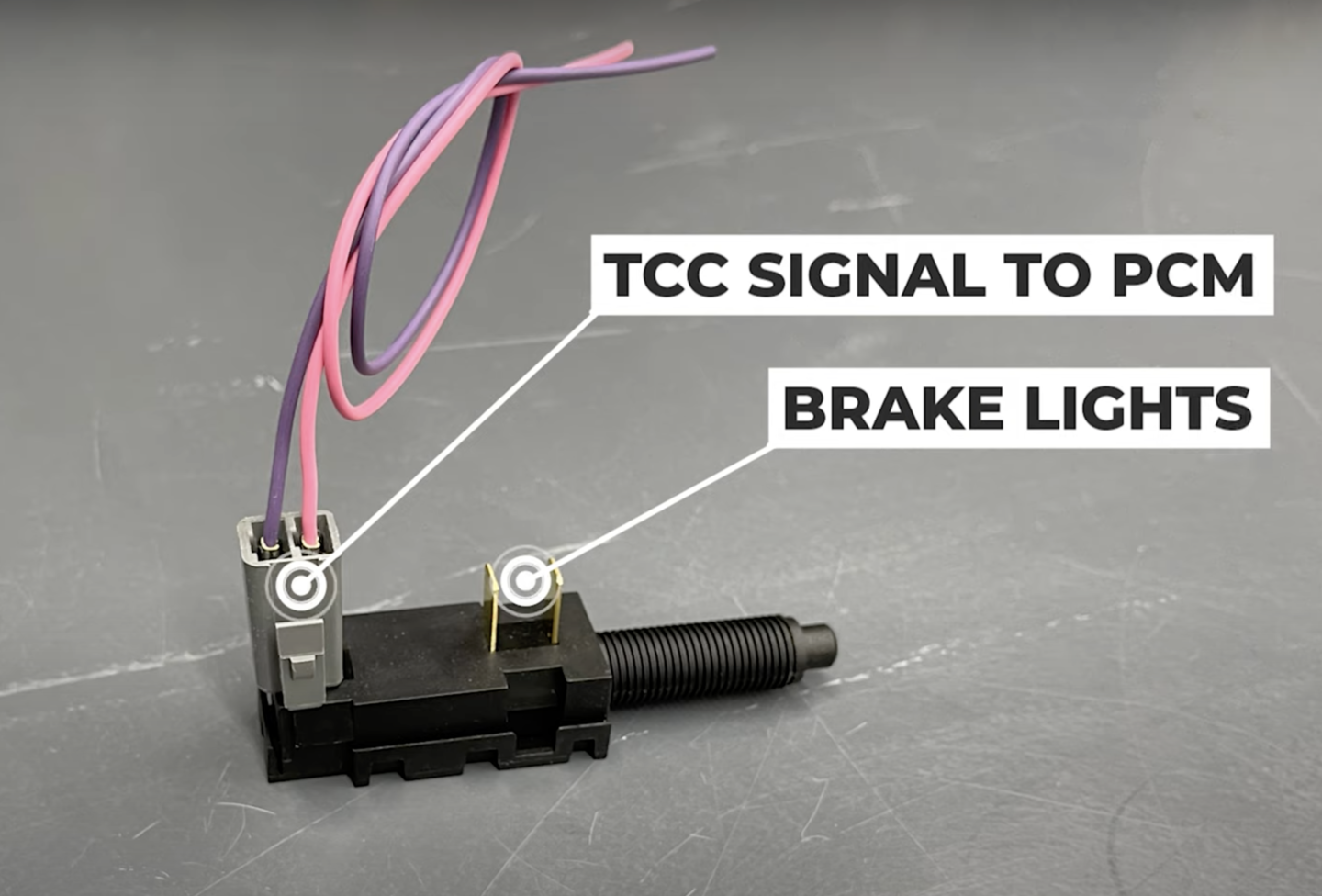

Installing the BP Automotive TCC switch is a snap if you have a brake switch with a 1/2-inch jam nut, which most GM vehicles do. First, you will remove the factory switch and unplug the wires for the brake lights. Next, you will plug the brake light wires onto the front part of the TCC switch. This will allow the brakes to work just like the factory. However, you might need to cut the plug off and add a set of female terminals in the worst-case scenario, which isn’t a big deal.

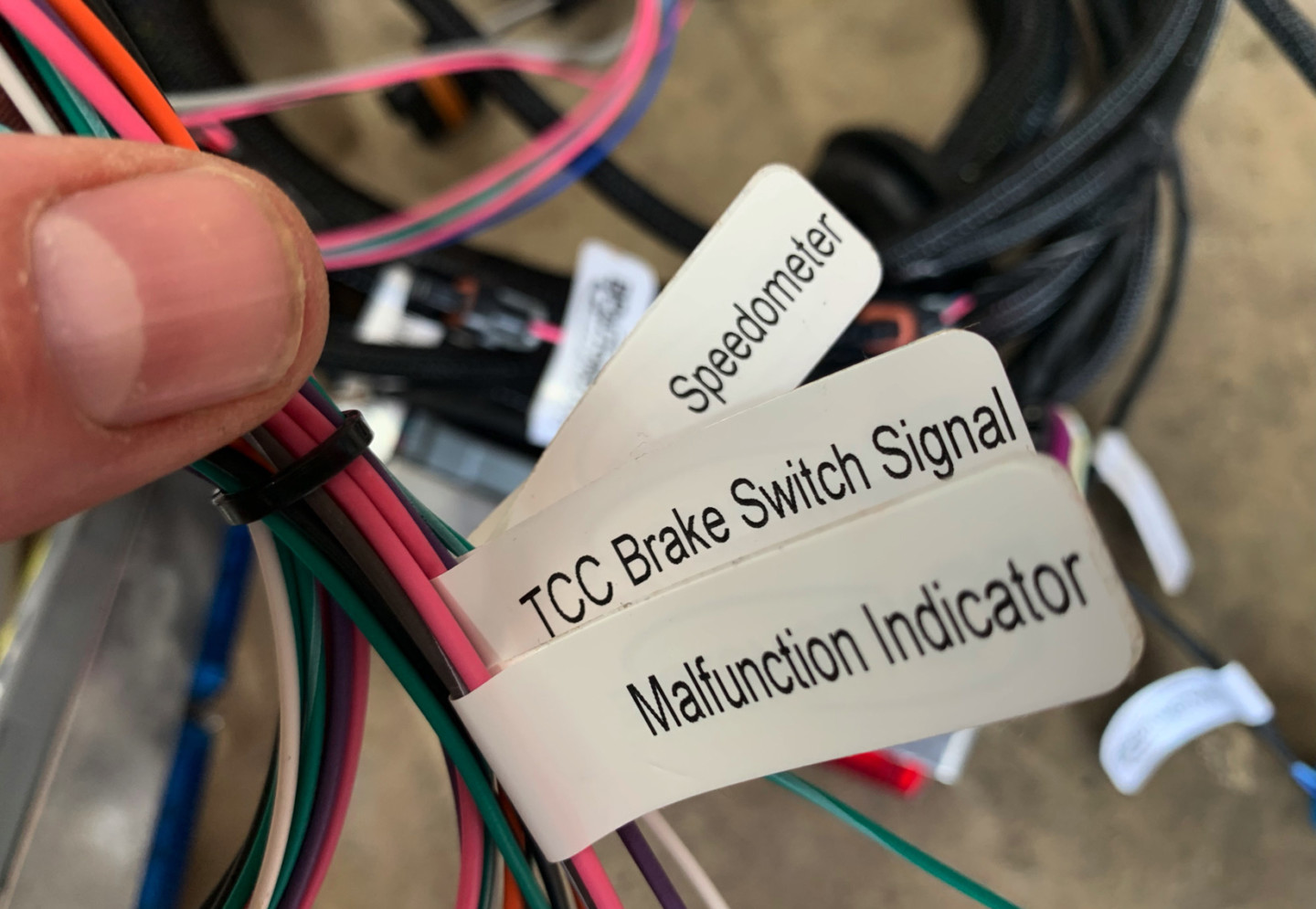

If you’re using a new BP Automotive wiring harness, the wires for the TCC are labeled and make for an even easier installation.

Then, you will take the supplied pigtail and connect the pink wire to a switched ignition source. Ensure that you do not hook this wire up to a constant 12-volt source, as it can cause quirky issues. The purple wire will then be attached to the TCC wire in the harness. With everything installed correctly, when the brake is pressed, the switch will send power to the ECU, letting it know the brake has been applied, thus unlocking the torque converter clutch.

Here you can see that our switch is all wired up and ready to go. All we need to do from here is plug the new unit in where the factory switch was located.

The TCC switch is available on BP Automotive’s website for only $25 and makes quick work of wiring in the TCC switch.