A lot of the installations on Project C700 have and will continue to be focused on increasing the horsepower and torque that the car puts down, or improving the cooling and aesthetics of our Stingray. This install, however, will focus on some products that help increase the handling aspects of the car, which will be crucial when participating in events such as autocross, and on road-course track days.

A lot of the installations on Project C700 have and will continue to be focused on increasing the horsepower and torque that the car puts down, or improving the cooling and aesthetics of our Stingray. This install, however, will focus on some products that help increase the handling aspects of the car, which will be crucial when participating in events such as autocross, and on road-course track days.

Additionally, for those of you who prefer to do more non-sanctioned, spirited driving on your local twisties and mountain roads, the following products can be equally as important to the handling improvements of your Corvette, and may just be what you’re looking for to pick up that extra bit of rigidity and cornering speed.

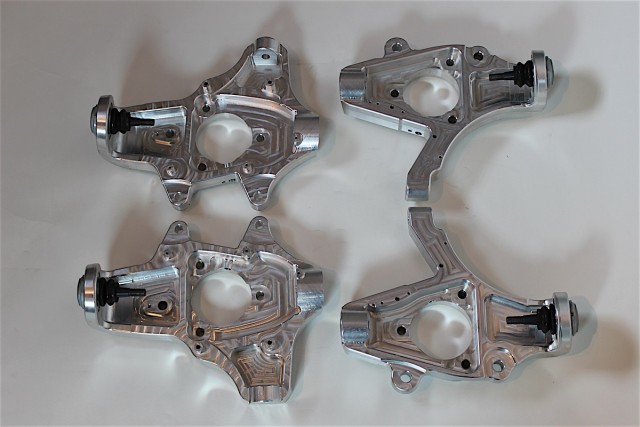

As you’ll see below, this install is comprised of two main components, both of which are produced by LG Motorsports. The first product we selected were 1-inch drop spindles, which improve handling in addition to changing the overall stance of the vehicle.

Drop Spindles

We had the opportunity to speak with Anthony Forney at LG Motorsports, who was happy to fill us in on on the new C7 drop spindles. Forney explained, “One of our key signature items here at LG Motorsports, are the billet drop and drag spindles. These have been used for well over 15 years now in some form on the Corvette platform. In recent years we developed a way to extrude the spindles to not only cut down on material loss but also machine time and thus a much lower cost to the end user. This has allowed us to drop the first sets on the C5’s from $6,500 a set to now under $3,000 a set.”

“Now you can drop the car and still have room for adjustment either with the factory leaf spring bolts or with our optional coil over kits for even further ride height changes from stock. Other benefits include a much stiffer wheel bearing mount for less deflection of the wheel and rotor assembly, and a stronger ear mount for the caliper for better pad wear.”

Fortunately, the spindles come with new balljoints already installed. Not only does this save on install time, but you don’t have to deal with removing the balljoints from the factory spindles or worrying about tearing a boot during removal.

For our installation, we were able to utilize BendPak XPR-10ALP lift to raise the car up into a standing workspace. That being said, most anyone with a floor jack, hand tools, and a can-do attitude can complete this installation without a hitch.

After lifting our Stingray up, we removed all four wheels and started upfront by removing and suspending the brake calipers out of the way. After unbolting the spindles, we pulled them free of the vehicle and set them on our bench to swap the rotors and hub assemblies over to our new billet spindles.

We then moved rearward and again removed the brake caliper. This was followed by unbolting the suspension and pulling the rotor and hub assembly free while also removing the rear axle. We then moved our parts over to the billet spindles, reattaching all suspension components along with the braking system.

You can see the transition in ride height here: Stock - Left, Lowered - Right.

Sway Control

The next LG Motorsports product we selected to improve the handling of our C7 was their sway bars. Forney went on to explain, “Our C7 sway bars were developed over months of testing with our Stingray R&D car. Even after six months of testing we were the first to market a ‘direct fit’ sway bar for the C7. We tested these with and without our G2 coilovers and on the new C7 Z06 platform after it arrived.”

Ferny continued, “We did some rather trick things – we have used on the race cars in years past to allow these new bars to fit within the confines of the OEM bracket hold downs, all the while increasing stiffness and retaining the hollow bar for weight savings. In addition we made the front bar two way adjustable so the home user can dial the car in a bit better as well. Z51 and Z06 users can see a 40 percent increase in stiffness, while base car owners are going to see their car turn into a corner animal given GM did not even grant the base car with a rear bar at all and a tiny front. Yet another product that has direct ties to our racing program.”

Effectively the way a sway bar, or anti-roll bar, functions is through twisting, versus compression like a coil spring – or in our Corvette’s case flexing the transverse mounted leaf. Cornering causes lateral acceleration which presents itself as body roll, effectively the suspension on the outside of the turn compresses, while the suspension on the inside extends. Because the sway bar is connected to both sides of the suspension, it is being twisted in opposite directions – the inside moves downward and the outside moves upward.

The stiffness or rigidity of this bar is what determines how much movement the suspension will see – the more rigidity the bar has, the less movement takes places under cornering. When placed side by side, you can see how much of a difference there is in the thickness of the LG Motorsports bars compared to the factory bars.

This is an important factor in improving the handling or cornering capabilities of a vehicle as a reduction in body roll will increase the contact patch of the tires, in addition to helping mitigate weight transfer through a series of corners, such as a slalom or chicane.

You may think that you would need a large change in diameter to change the handling of a car considering the weight, but this isn’t the case due to the the rules of torsional rigidity. If you’re into this sort of thing, the formula is: twist = (2 x torque x length) / (π x diameter4 x material modulus).

The important factor here being that if you had a round, solid steel bar of -21|mm and upgraded to a -22|mm bar, you have increased stiffness by 20 percent. A little goes a long way.

So now that you know how to make your car stiffer, you may be thinking the thicker the bar the better … well not exactly. Ride comfort and other such items aside, you are still better off with some suspension travel than none. If you select a bar that is too stiff, you will actually begin lifting the inside tire under hard cornering, and completely eliminating your inside contact patch altogether.

The next portion of our install involved unbolting the sway bars and removing them from the vehicle. Should you chose to complete this install on your own you will see that you have to twist the bars appropriately to free them, but they do come out without removing any major parts of the car.

From here, simply insert the new rubber grommets that are sized correctly for the new bars, and attach your new end links on all four corners.

The Ride

We know that we’ve technically added two variables into our experiment here, but theses two modifications go hand-in-hand for our purposes. The first thing we noticed on our ‘Vette was the new aggressive stance, and for those of us that prefer our cars low, now it looks “right.” We set the key fob under the front right corner so you have an identical reference point to see what the actual drop would look like on your Stingray.

You do have to be a little more cautious when it comes to steep driveways and transitions, but the look and improved handling are well worth performing a crooked approach now and then.

The owner of C700 mentioned, “The suspension upgrades produced a pretty impressive and dramatic improvement in handling, especially with aggressive driving. The car stayed flatter coming out of corners, and I think the sway bars and lowered ride height lowered the center of gravity of the car. The ride was firmer, and given the magnetic ride control, I’m not sure if this is a result of sway bars but I think that’s the most likely. Given that we only took the car to Willow Springs after the upgrades, I don’t have a specific after to reference, but the car was a blast at willow. Dependable, rock solid, and I could employ the throttle aggressively through a variety of different cambered curves and situations without any fear of the car coming around on me.”

We can’t wait to see how our new LG Motorsports modifications do when we hit the road course and really let our C7 do what it does best.