As we mentioned in the previous C700 build, a lot of the installations on Project C700 have, and will continue to be, focused on increasing the horsepower and torque that our car puts to the ground, a couple of installations on increasing the handling or cornering characteristics, and even a few products to keep our Stingray running cooler when it’s at the track.

As we mentioned in the previous C700 build, a lot of the installations on Project C700 have, and will continue to be, focused on increasing the horsepower and torque that our car puts to the ground, a couple of installations on increasing the handling or cornering characteristics, and even a few products to keep our Stingray running cooler when it’s at the track.

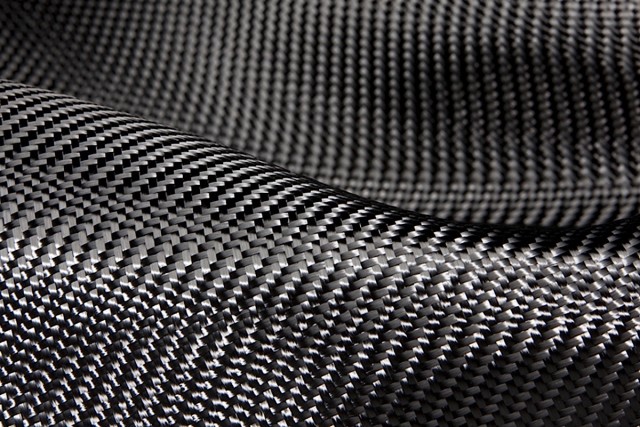

This install, however, will be focusing on components that have been crafted from many car enthusiasts’ favorite composite – carbon fiber.

What Are We Working With?

All of the components that you are seeing here are constructed with carbon fiber. Most people are familiar with the appearance of it, but for those who aren’t sure what it really is, we asked our resident composites expert to help fill you in.

Turnology Editor Trevor Anderson explains, “Carbon fiber is an industrial textile comprised of thousands of carbon filaments woven together to create cloth. It is produced in a variety of different weaves for different applications, and is only one part of a multi-part structural material known as a composite. Composites are just things made from combining the qualities of different materials to complement weakness or strength.”

Turnology Editor Trevor Anderson explains, “Carbon fiber is an industrial textile comprised of thousands of carbon filaments woven together to create cloth. It is produced in a variety of different weaves for different applications, and is only one part of a multi-part structural material known as a composite. Composites are just things made from combining the qualities of different materials to complement weakness or strength.”

Anderson continues, “In the case of carbon fiber, fiberglass, Kevlar, and other such textiles, the composite in question is known as an FRP (fiber reinforced polymer). In a FRP, cloth is used to bolster the structural rigidity of a resin substrate. Resin provides the strength in the composite and the carbon fiber provides structural integrity to the otherwise brittle plastic.” If you would like to learn more about this beautiful composite, you can delve into the topic with this article.

Just as we did previously for our drop spindles and stiffer sway bars, we sourced our products from LG Motorsports, one of the leading manufacturers when it comes to quality aftermarket performance performance products.

We had the opportunity to speak with Anthony Forney who explained, “The C7 carbon items were developed in part, before the C7 even was released to the public. Our G7 splitter and side skirt design was actually awarded the 2013 SEMA Design award for ‘Best Cheverolet Accessory’ on the C7 Corvette. It really gives the C7 Stingray a much more aggressive visual stance, along with helping aid in aero on the car by added downforce. Our underhood items are true carbon and 100 percent replacement pieces. These are not the typical hydrocarbon that you see places applying or using overlays for the factory pieces. This gives you a true carbon part with a lighter weight benefit, as well as the look!”

The Install

The installation required of our carbon fiber parts is a little different than most of the mechanical style that we’re used to. For this job you’ll want to make sure you have the time and perhaps a spare set of friendly hands as you don’t want to see any scratches or scuffs in your beautiful new carbon.

With a relatively cool engine compartment, we opened the hood and began removing the factory intake plenum cover, the intake side covers, and coil covers. There are a couple of bolts holding the coil covers in place, and the intake cover on top simply pops off of its studs. The only other piece you’ll have to remove and reattach, is the vent hose which runs through the coil cover on the driver’s side.

The soft liner underneath stays on the intake plenum, and the liners on the factory coil covers should be transferred over to the carbon pieces as well. These three parts simply snap or bolt back into place, and the new aesthetic really adds a different look to the LT1.

Our next piece to change over was the large portion in the engine bay which directs the air that has passed through the radiator, on up, and through the heat exchanger the hood. This is held on with a handful of screws that run across the upper edge of the part and make for a very quick swap. Considering the curves and functionality, this was our favorite component of the engine dress-up section.

Next up we opted to swap out our factory louvered heat exchanger, or hood vent, for the new carbon fiber part. For this portion we first removed the under-hood liner. Next, we removed the factory exchanger with a little help from a specialized automotive interior tool. If you don’t already own them you can get an entire set quite inexpensively online as they are made entirely of plastic. We were a little skeptical to apply the amount of force needed to pull the tabs free, but with a consistent application, they popped free unharmed. From there we simply slid the clips into place and set our new heat exchanger into the hood. The carbon really looks great as a centerpiece on the Stingray hood. This wraps it up for any parts under the hood, and we’re moving to the exterior.

The exterior carbon is comprised of three pieces, two side skirts and a front splitter. To make this portion of our install a little easier, we opted to drive our C7 onto some Race Ramps for easier access. The splitter bolts to the existing holes in the bumper and attaches in minutes. Unfortunately, we had to remove the protective skid plates from underneath the bumper, but they have served us well to this point.

The carbon fiber front splitter is an excellent piece, and with a shape that mostly mirrors the factory bumper, it does not seem at all intrusive when you walk past. That being said, you certainly will notice it and will see how it changes the overall appearance and attitude of your C7.

The final portion of our carbon fiber installation involved fastening the side skirts to the car. These use a combination of screws and rivets to ensure they’re properly fastened to the ‘Vette. Again, the installation went rather quickly and we found that the fitment of the side skirts left nothing to be desired.

Aside from looking great, the exterior sections of our carbon fiber kit adds aerodynamic efficiency by moving more air over and around the car, rather than underneath. Redirected air can now flow through the bumper opening and cool a few different items up front, while removing part of the airflow from underneath the car should improve high-speed stability as well. In fact, if you can remove enough air from underneath your vehicle while subsequently moving high-speed air over the surface of the car, it creates a low-pressure situation under the car. This simply increases downforce – the reason why a Formula 1 car could theoretically drive down the ceiling of a tunnel while at speed.

Left: Before Right: After

While we don’t anticipate our splitter and side skirts will push our Stingray past the points of mechanical traction, we welcome any improved stability, and advantage in aerodynamics. If that doesn’t interest you, the fact that it looks awesome should!

Conclusion

Overall we are extremely happy with the way all of our LG Motorsports carbon fiber pieces turned out. If you’re into carbon fiber like we are the parts are truly gorgeous, and the engine dress package just adds the subtle extra touch to your Stingray, even if you are one of the few that will ever see it.

The exterior parts look awesome, and combined with the lower stance from our LG Motorsports drop spindles, the car has taken on an entirely new, more aggressive look altogether. We hope to experience some increased aerodynamics and we can’t wait to run the new setup out on the road course.

Those of you that have been following along with Project C700 may have noticed some sweet new Forgeline wheels sitting in place of our factory black Z51 wheels in these pictures, so stay tuned for an in-depth look at what tire and wheel choices we made, and further testing results out on the road circuit.