It’s starting to sound a bit repetitive. We knew going into this project that there would be quite a few things that needed to be addressed to get Project Honey Badger back into fighting shape. In the car’s previous life, sticky tires and a twin-disc clutch dump at the dragstrip turned the rearend into box of rocks. Fortunately, both the rearend and the T-56 were rebuilt with better-than-stock parts.

However, the car never really shifted great. The shifting was really sloppy, which could easily be attributed to the remote shifter linkage inherent to a transaxle setup. However the fairly regular popping out of first gear and reverse was an indicator that besides worn out 25-year-old guts of the stock shifter, there might be other issues. Fortunately for us, Tick Performance makes a shifter that will bring crisp shifting back to our 2000 Corvette.

In order to improve on the stock shifter assembly, Tick took a clean sheet approach to the problem. Rather than just design a ball-and-stick replacement with a little geometry applied to the pivot points, the engineering team redesigned the entire shifter assembly. Not only to improve the design, but to also make sure the customer is getting all new components and doesn’t have to rely on any worn-out stock parts.

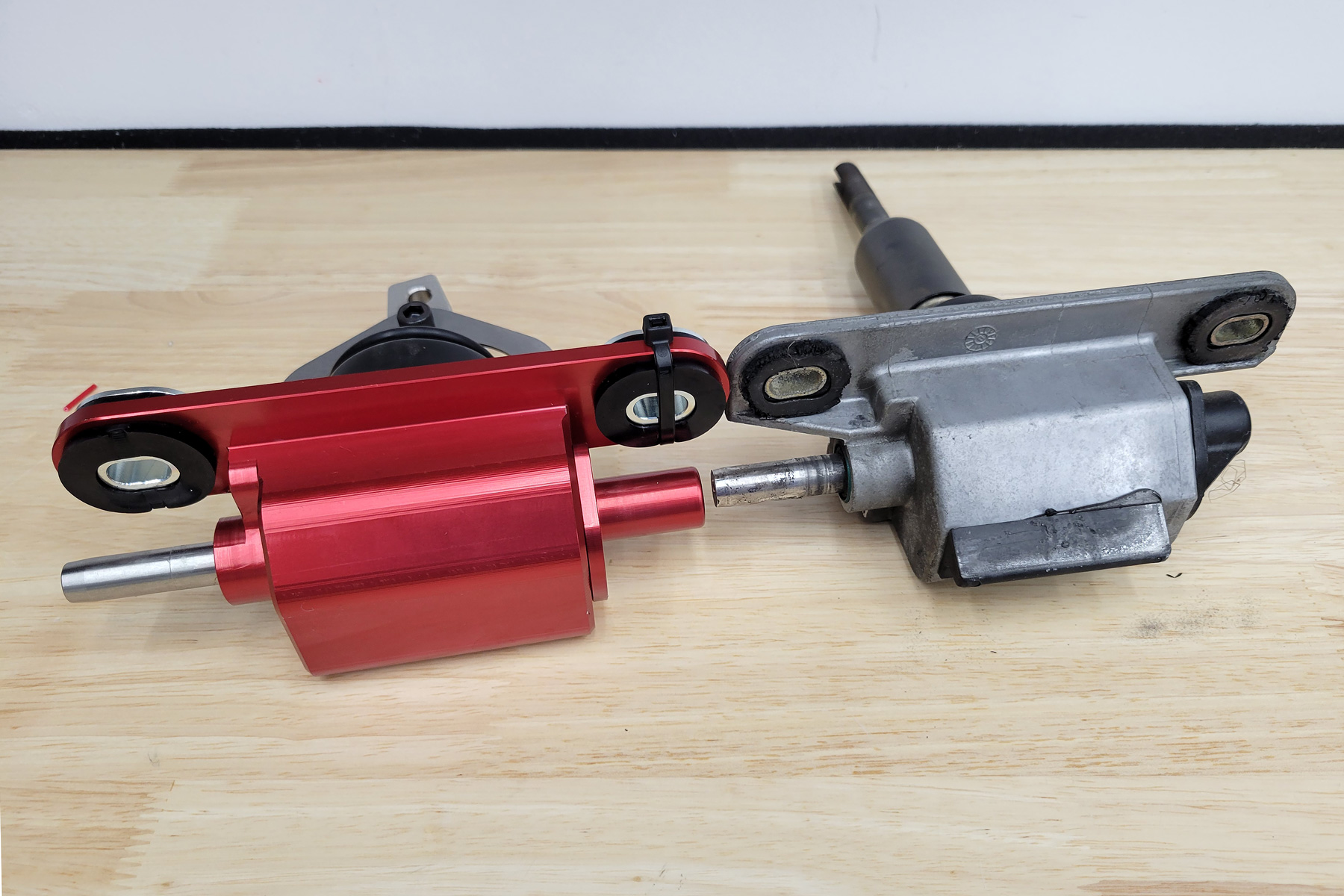

Here you can see the marked difference between the Tick Performance shifter, with its billet self-contained design compared to the OEM C5 Corvette shifter. The top of the shifters is on the left, and the bottoms are on the right. You can also see the difference in the bushings the Tick Performance shifter uses for a much more solid mount to the chassis.

Made from a billet aluminum housing with steel shift linkage, the Tick Performance shifter design is weather-sealed to improve longevity compared to the stock design. The internal components provide a 15-percent reduction in shift throw with much tighter tolerances for a tighter, more precise shift feel.

Adding to that are the redesigned mounting bushings, that use a higher durometer rubber along with steel inserts for a much firmer mounting to the chassis than the stock shifter. Another benefit of the self-contained shifter design is a simple three-bolt drop-in installation of all-new parts.

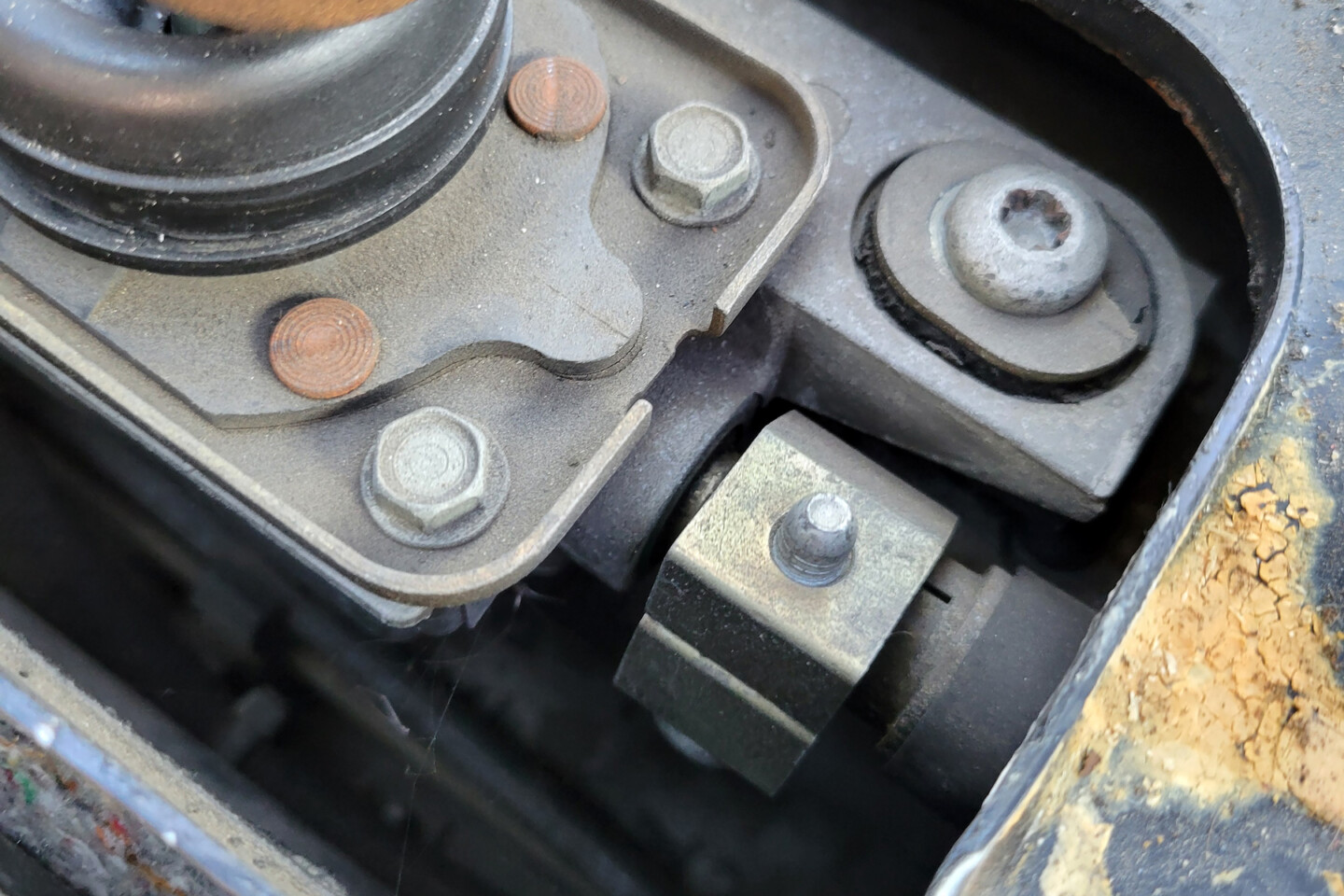

Well, the installation would have been a walk in the park, if we hadn’t found the reason for the shifter popping out of gear. After removing the console components, we found the shift linkage collar installed upside down. We determined that when the transmission was reinstalled previously, the collar was flipped upside down, so that it could be run down with an impact gun from the under the car.

This little guy added a week to the project. This collar is supposed to have the bolt facing up and is one one of only three bolts you need to remove to remove the stock shifter. We were forced to cut the old collar and bolt off and install a new one.

This caused two issues. First, there is no way to loosen the collar from the top side, because the bolt is upside down, and there is no way to get at it from the bottom, with the torque tube and exhaust installed. That also explains why the shifter pops out of gear — there was no way to adjust the shifter once everything was installed, so that misalignment was never addressed.

Once a new collar and bolt were acquired, the install could commence. Thanks to the centering bracket that comes with the Tick shifter, the install was a breeze. It was literally just drop it in and bolt it down. Once the shifter was locked into place, we removed the centering bracket and then bolted on the stick.

The shifter stick is a neat design, in that besides the traditional two-bolt stick attachment, it is also keyed, making the connection even more secure. It is also machined to accept a C6 or C7 shift knob, or any traditionally threaded knob in 9/16-18. If you want an aftermarket knob, Tick has you covered there as well.

This centering brace keeps the Tick shifter assmebly dead-center during the installation procedure, so there should be no adjustment needed once the shifter is installed.

Tick Performance has a number of shift knob designs, but when it comes to both style and functionality in Arizona, the only option in our eyes was the Tick Delrin shift knob. Besides the cylindrical design that appeals to our tastes, the CNC-machined Delrin material is a high-density acetal resin that is remarkably impervious to both hot and cold extremes, both of which we see here.

The host of features and ease of installation are great and all, but realistically, the main point of judgement for the Tick Performance shifter is the shift quality. Now, with a rear transaxle, shifting is an engineering challenge. Having driven quite a few front-engine transaxle Porsches in my time, my expectations were in check. However, the Tick Performance shifter provides better shifts than I could have ever have asked for. To say it is a night and day difference between the stock shifter and this is an understatement.

Besides the extremely positive engagement in each gear, the Tick Performance shifter cures the mystery neutral position the stock shifter had. The worn stock shifter had zero centering action in neutral so finding gears was a crapshoot. Now, the firm centering action makes finding gears a breeze. And, the transmission doesn’t pop out of first and reverse anymore.

This was definitely one of the most satisfying modifications I’ve made to Project Honey Badger. In a sea of doing things just to get the car back into fighting shape, it’s nice to make a bona fide improvement that can be fully enjoyed every time the car leaves the driveway.

On the left, you can see the Tick Performance Delrin shift knob. Besides being a pleasing design, the Delrin material will handle extreme temperatures without transferring them to your hand. A nice plus in Arizona. On the right, you can see the shifter is threaded 9/16-18, and also machined for a stock C6 or C7 shift knob, if you prefer something other than the Tick Performance knob designs.